Oil field well head sleeve tube gas sampling equipment

A gas sampling and casing technology, used in wellbore/well components, earthwork drilling, etc., can solve problems such as production failure, personal safety risks, interference with analysis results, etc., achieve tight sealing, ensure personal safety, The effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

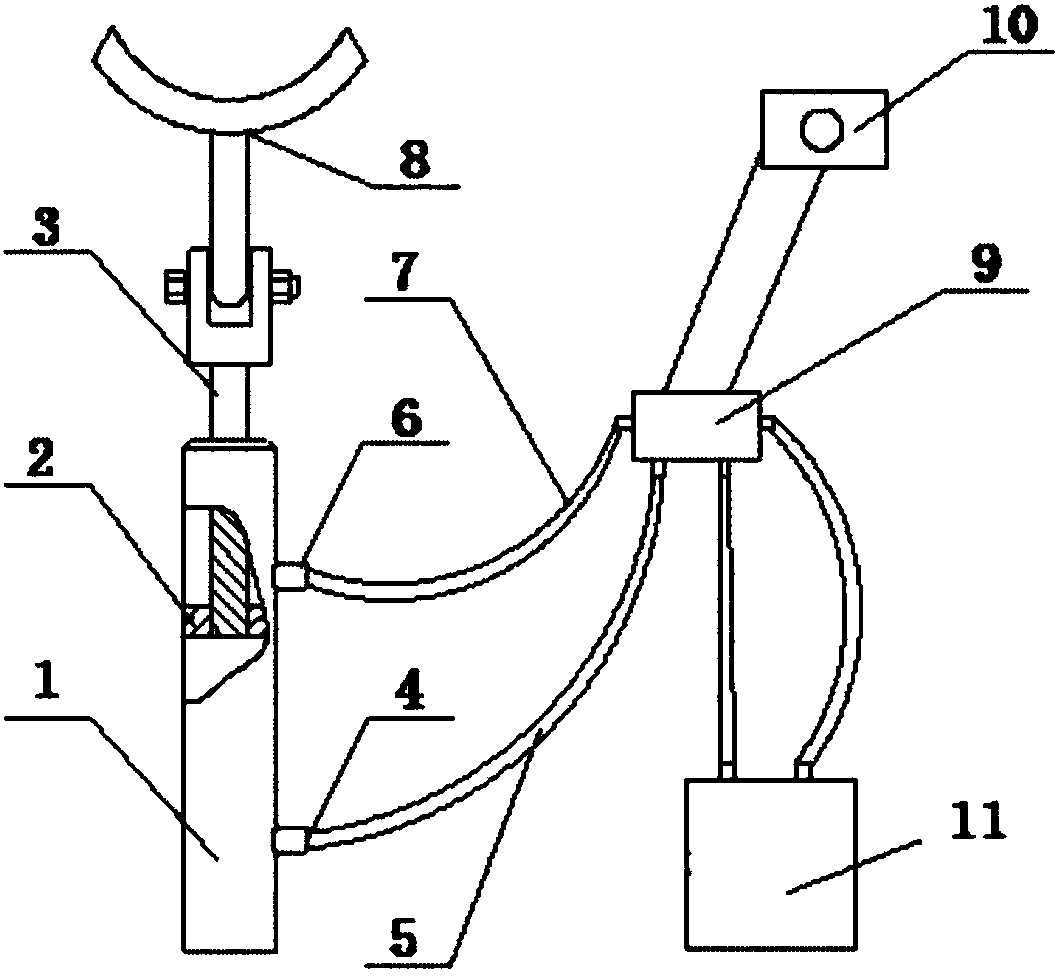

[0016] see figure 1 , the invention discloses an oil field wellhead casing gas sampling device, the sampling nozzle 10 has a tubular sampling nozzle body 1, and the two ends of the sampling nozzle body 1 are respectively a fluid inlet port and a fluid outlet port; the fluid inlet port An interface 2 that can be connected with the wellhead casing of an oil well is formed, and a sampling interface 3 that can be sealingly connected with a sampling bag 7 is formed at the fluid outlet end. The interface 2, the sampling nozzle body 1 and the sampling nozzle 3 form a fluid channel. During the process of collecting the gas sample of the casing, the fluid flows through the fluid channel, which can effectively prevent air from mixing into the collected samples, thereby avoiding air to the casing. The component results of gas sample analysis and analysis cause interference and mislead production.

[0017] In a specific embodiment, an external thread matching the internal thread of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com