Pressure sensor arrangement for detecting a pressure of a fluid medium in a measurement chamber

A pressure sensor and fluid medium technology, applied in the direction of measuring fluid pressure, measuring instrument components, measuring devices, etc., can solve the problems of high component cost and connection process cost, reduced connection stability, cracking, etc., and achieve simplified weight and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

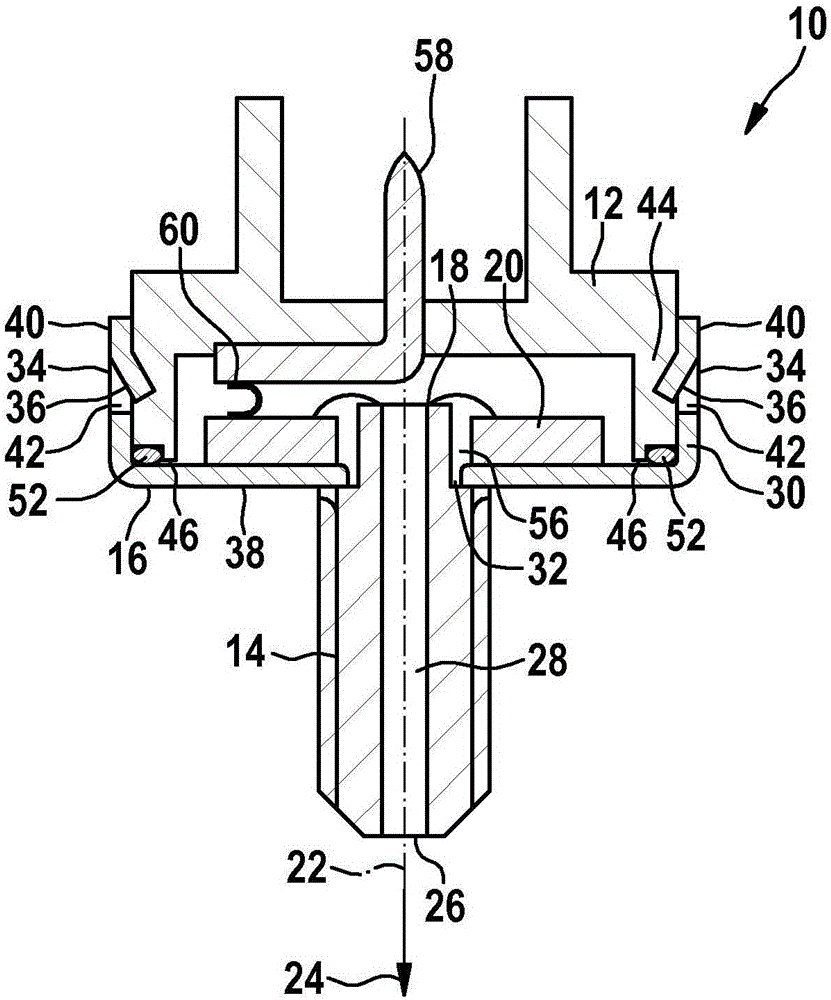

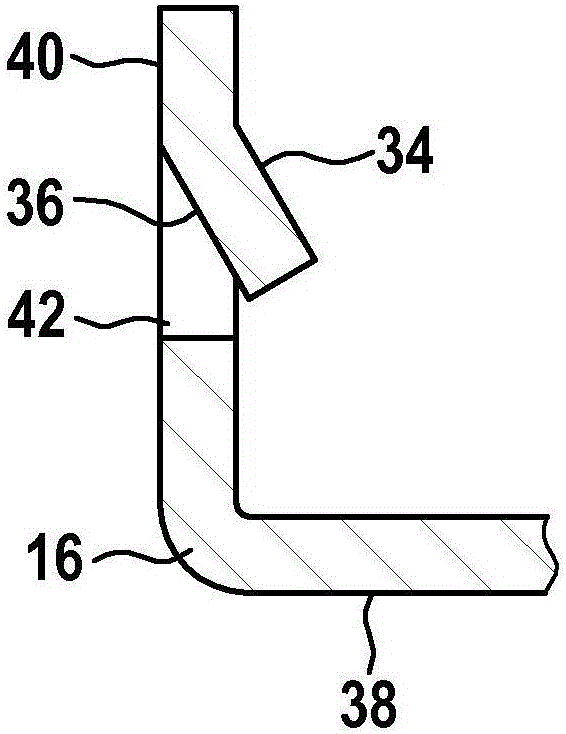

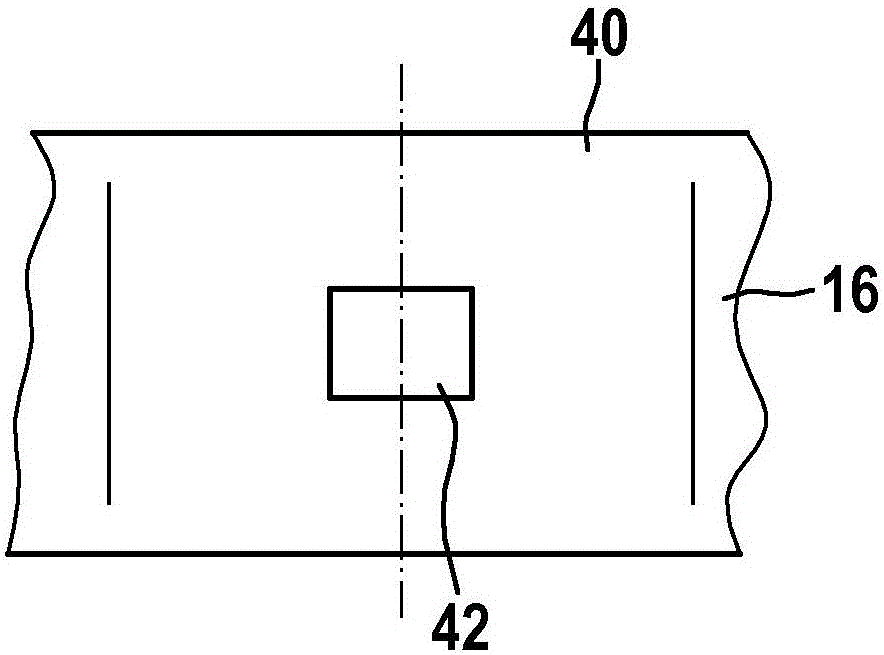

[0020] exist figure 1 A cross-sectional view of an exemplary embodiment of a pressure sensor assembly 10 according to the present invention is shown in . The pressure sensor assembly 10 can be designed, for example, to sense the fuel pressure in a fuel line of an internal combustion engine. The pressure sensor assembly 10 includes a sensor housing 12 , a pressure fitting 14 , a housing base 16 and a sensor element 18 . A printed circuit board 20 with an evaluation circuit (not shown in detail) is mounted, for example glued, on the housing base 16 , which is provided for outputting a signal indicative of the pressure acting on the sensor element 18 .

[0021] The pressure connection 14 can be made of metal and can be designed as a cylindrical pressure connection, in particular a screw connection, the cylinder axis 22 of which coincides with the longitudinal extension direction 24 of the pressure sensor assembly 10 . At one end, the pressure connection 14 has an opening 26 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com