Fluidization unit and discharge system

一种流化、排放管的技术,应用在化学仪器和方法、运输和包装、分离方法等方向,能够解决低效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

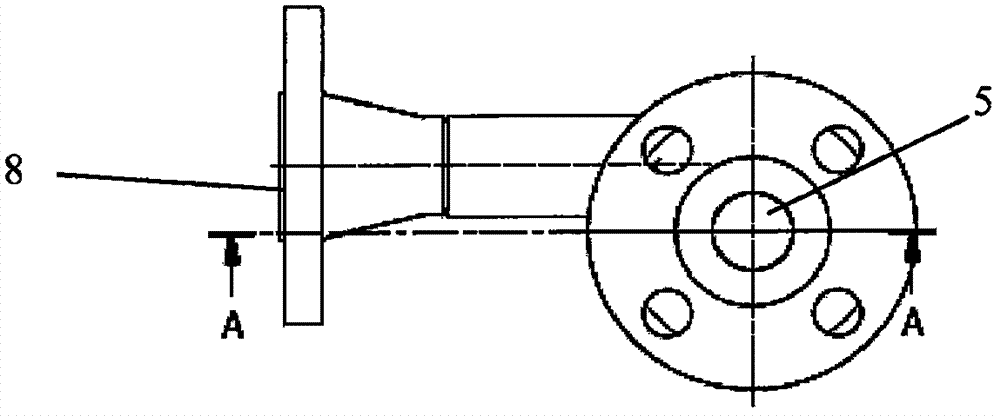

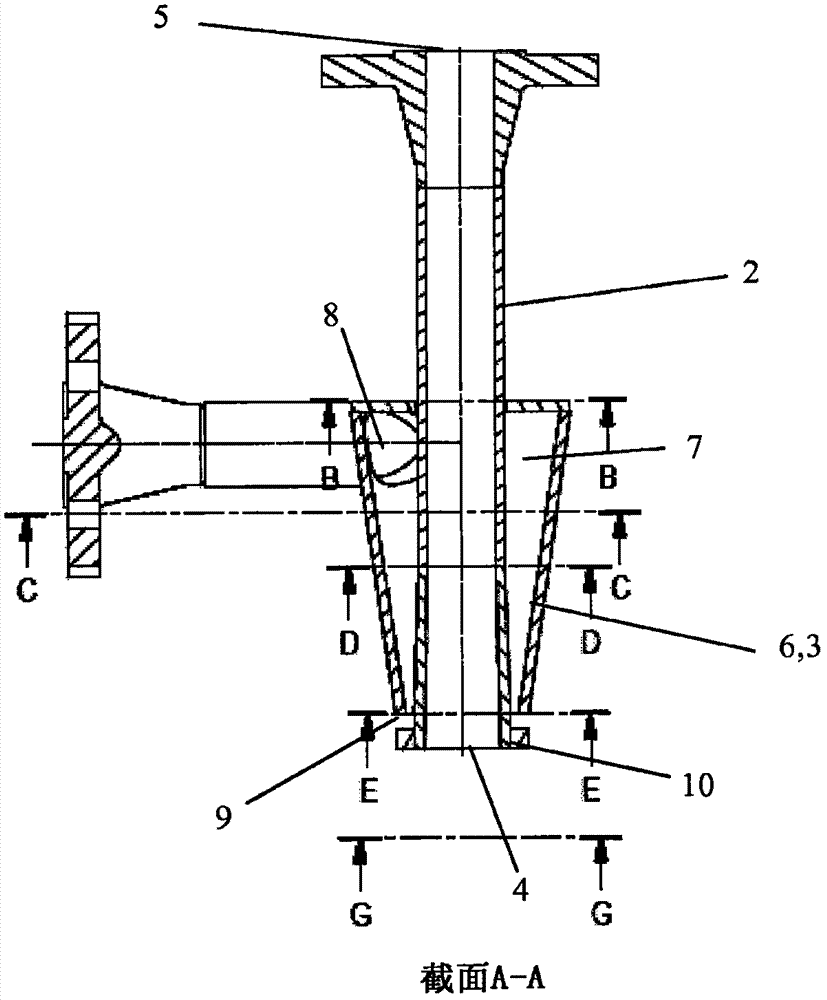

[0027] figure 1 An embodiment of a fluidization unit according to the invention is shown. The unit is designed to be incorporated into a vessel desanding system for removal of accumulated solids / sand. The unit can be operated in on-line desanding mode, or in batch desandering operation during routine maintenance. The unit includes a discharge pipe 2 for removal of fluidized solids. The suspension including fluidized solids is sucked into discharge inlet 4 and removed through discharge outlet 5 . Solids are fluidized by the use of pressurized liquids, usually water. This liquid is introduced into the supply conduit 3 through the inlet 8 . The supply conduit 3 comprises a casing 6 arranged around the discharge pipe 2 . The inner surface of the casing and the outer surface of the discharge pipe provide an annular space 7 between them. see Figure 6 and 7 , in a plane substantially perpendicular to the centerline of the discharge pipe, the cross-section of the annular spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com