Insulation Adhesion Test Radial Cutting Device

A cutting device and adhesion technology, applied in metal processing and other directions, can solve the problems of low work efficiency, high labor cost, safety addiction, etc., and achieve the effect of improving cutting efficiency, simple structure of the whole machine, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

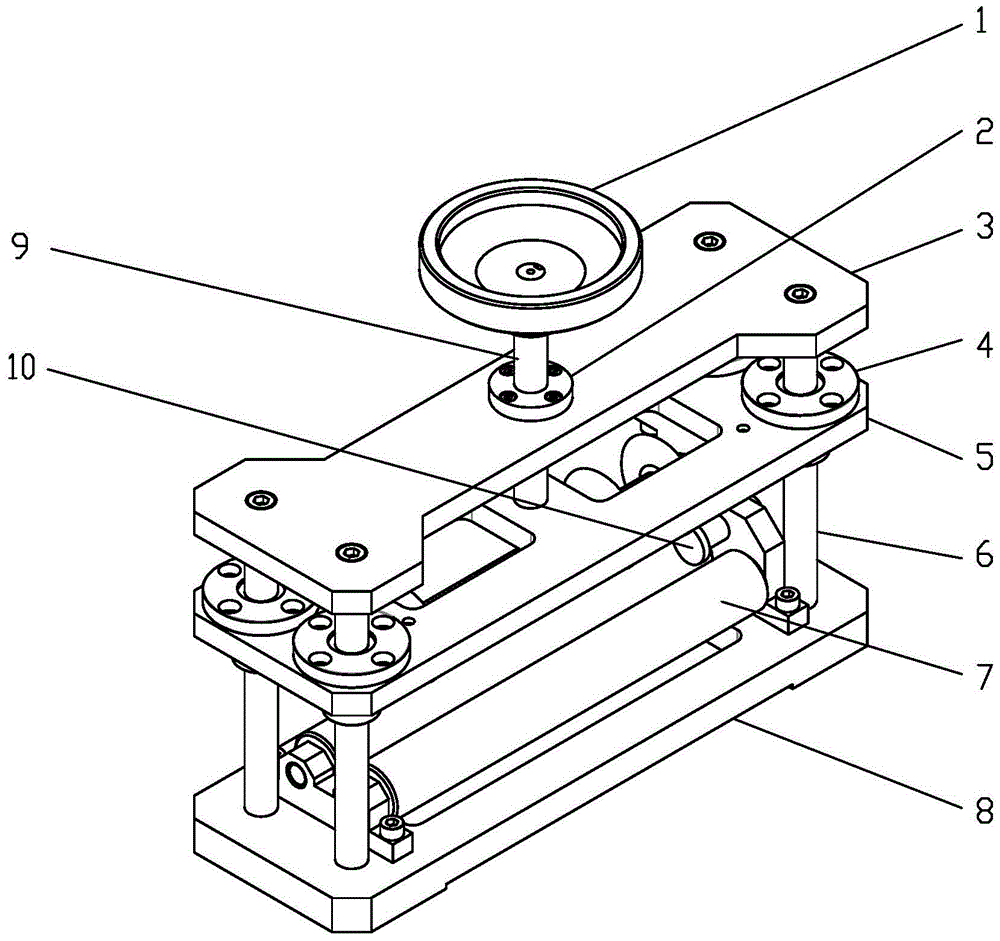

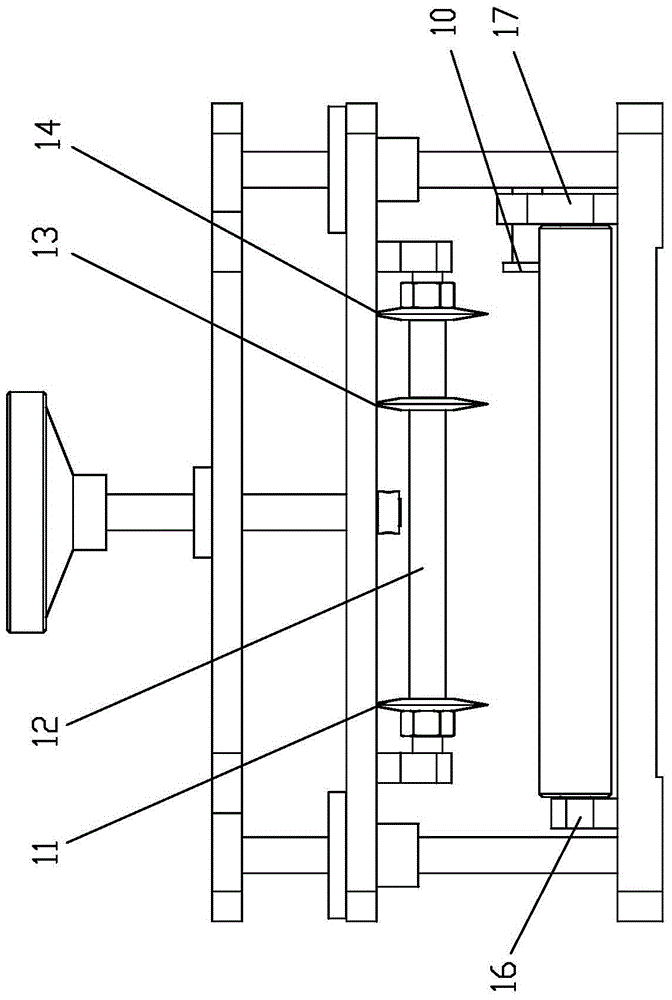

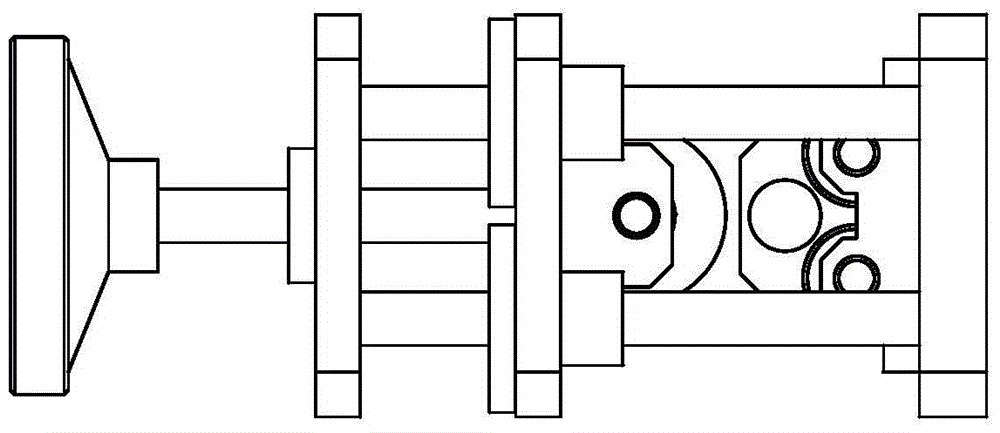

[0028] refer to figure 1 , figure 2 and image 3 , The radial cutting device for insulating adhesion samples of the present invention includes a base 8, a top plate 3, a movable support 5, a column 6, a hand wheel 1, a wheel shaft 9 and a pair of rolling shafts 7. There are four columns 6, and the two ends of each column 6 are respectively fixed on the base 8 and the top plate 3. The movable bracket 5 is sleeved on the column 6 . The wheel shaft 9 is arranged on the top plate 3 , the top is fixedly connected with the handwheel 1 , and the bottom is screwed with the movable bracket 5 . The bottom of the movable support 5 is provided with a blade shaft 12, and the blade shaft 12 is provided with three blades 11, 13, 14; the distance between the blades 11 and 13 is 100 mm, which is the insulation layer test length specified by the national standard. Both ends of the base 8 are respectively provided with a rolling shaft mounting block 16, 17, the pair of rolling shafts 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com