Punching and cutting die for end portion of wire collecting pipe

A tube end and punching die technology, applied in the field of terminal and controller matching processing device, can solve the problems that the quality of crimping cannot be guaranteed, the reliability cannot be guaranteed, and the production efficiency is low, so as to change the chaotic situation, resist the Guaranteed tensile strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

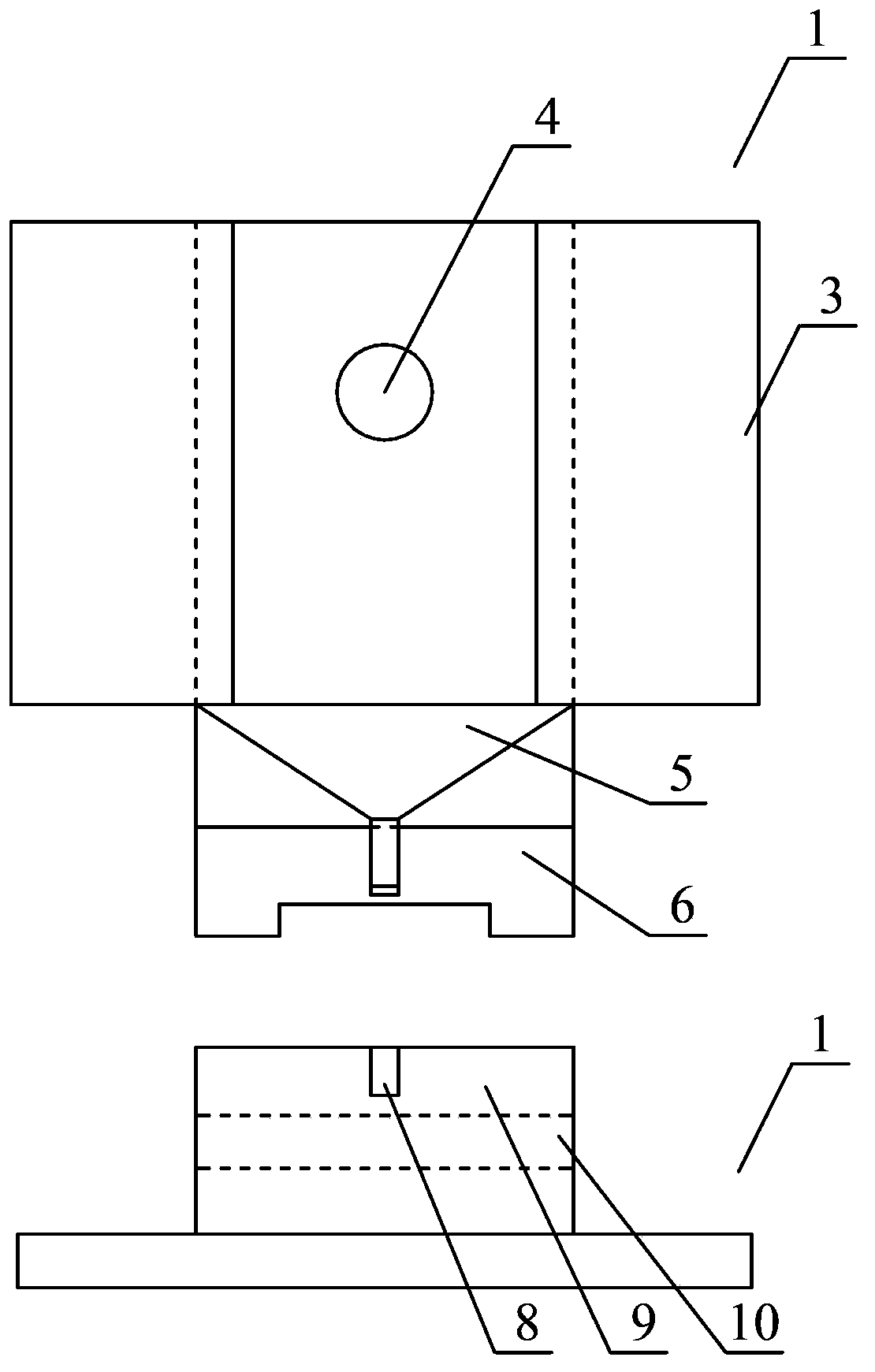

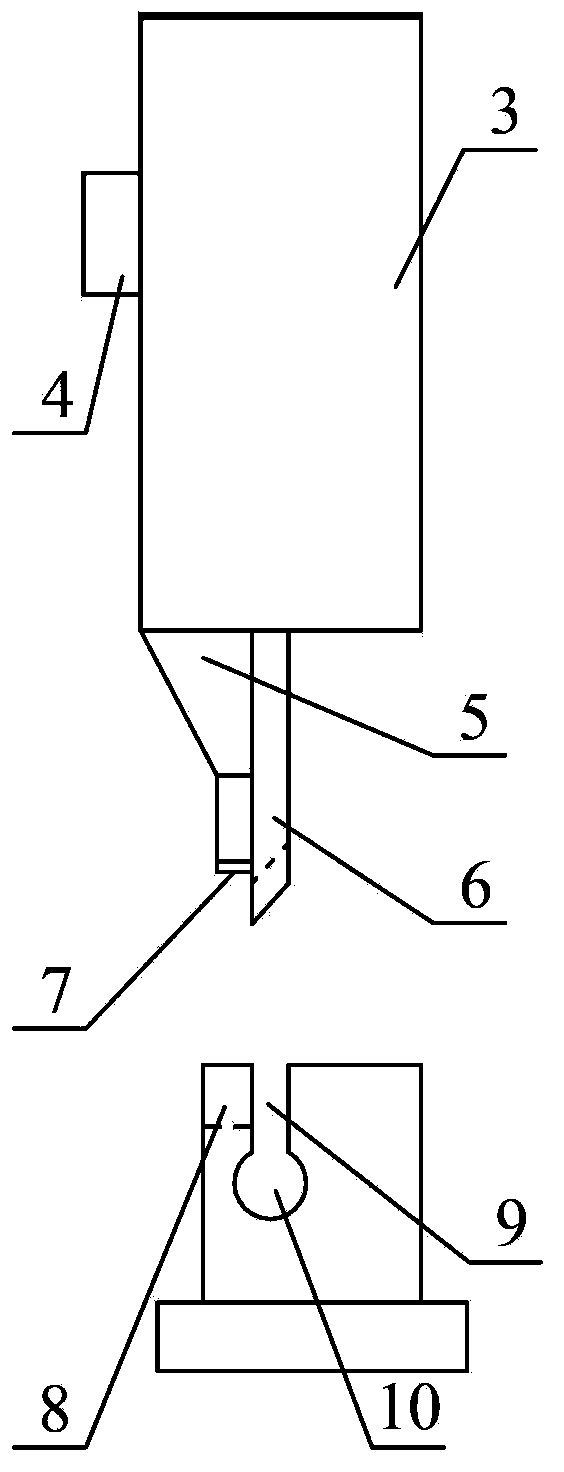

[0016] Such as figure 1 with figure 2 As shown, the present invention includes an upper die 1 and a lower die 2, and the upper die 1 includes a mounting part 3 and a punching die 5 and a cutting die 6 installed on the mounting part 3 by bolts 4, and the punching die 5 is located in the Cutting die 6 outside, and the center line of described punching die 5 and described cutting die 6 is on the same vertical plane, described punching die 5 lower end surface is provided with the bar-shaped protrusion 7 parallel with described punching die 5, so The position of the lower die 2 corresponding to the die 5 is provided with a vertical groove 8 , and the position corresponding to the cutting die 6 is provided with a horizontal groove 9 .

[0017] The lower end of the horizontal groove 9 is provided with a cylindrical through groove 10 .

[0018] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com