Guide rail-type construction hanging basket for chimney beacon paint and construction method

A guide rail type and chimney technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of unstable center of gravity of construction workers, small painting area, and difficult construction, and achieve disassembly and assembly Convenient and fast, improve construction efficiency and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

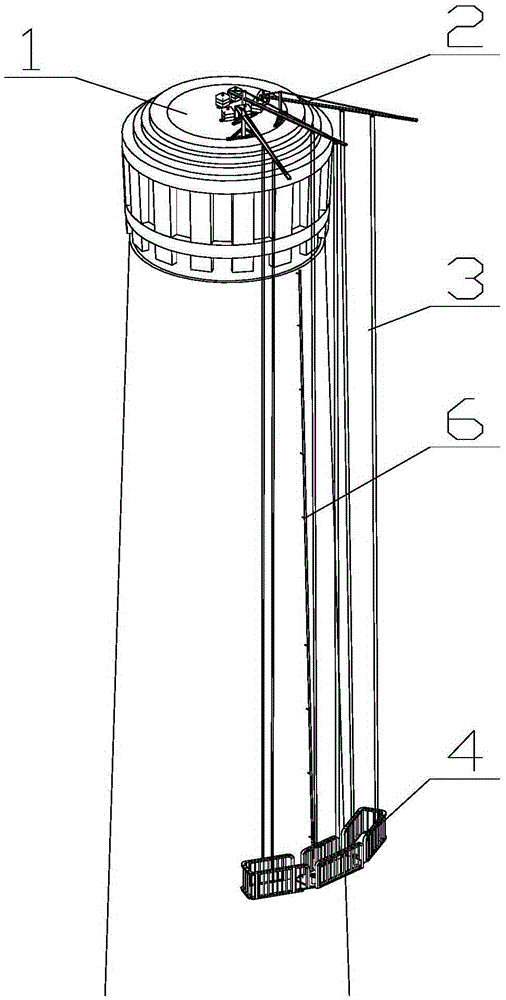

[0039] In one embodiment of the present invention, the implementation method of using the chimney navigation mark paint guide rail type construction hanging basket includes the following steps:

[0040] 1) Hoist the device to the temporary platform erected on the top of the chimney, and first connect and fix the rotating platform 1 to the top of the chimney;

[0041] 2) Determine the positions for fixing multiple hangers 2 according to the actual size of the site, and fix the hangers 2 on the rotating platform 1;

[0042] 3) One end of the hanger 2 is connected with the hoist on the hanging basket platform 4 through the wire rope 3;

[0043] 4) After hoisting the hanging basket platform 4 to a height of 50 mm from the temporary platform by the hoist, the construction personnel enter the hanging basket platform 4 together with construction tools and guide rails;

[0044] 5) The hanger 2 extends outward to move the hanging basket platform 4 towards the outer wall of the chimney...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com