Damping roller type electric two-way tamping machine

A vibration-damping roller and tamping machine technology, which is applied to the upper structure of the track, roads, tracks, etc., can solve the problems of easy swing, the tamping machine cannot meet the operation requirements, and affect the working efficiency of the tamping machine, so as to improve the use of the tamping machine. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

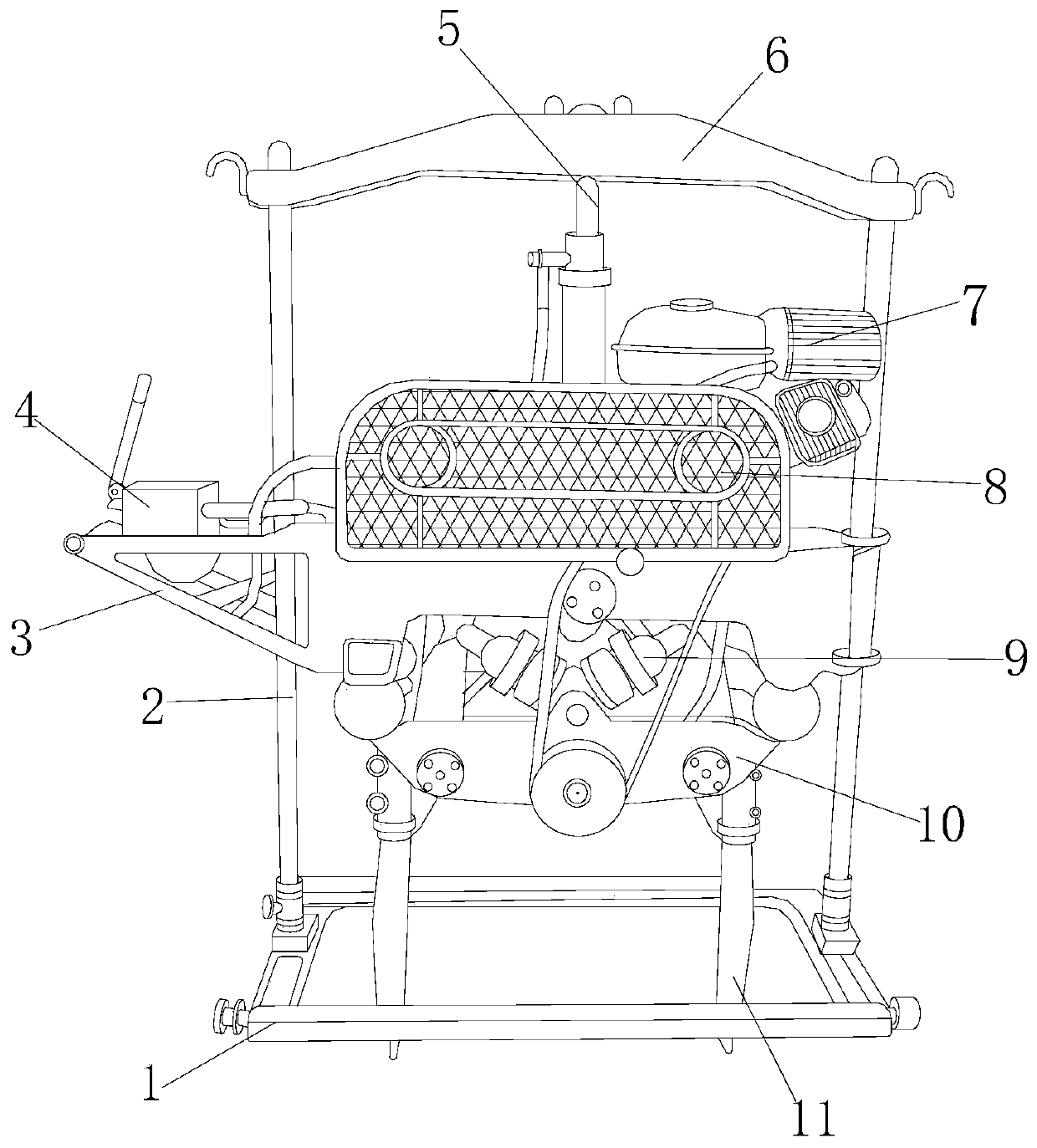

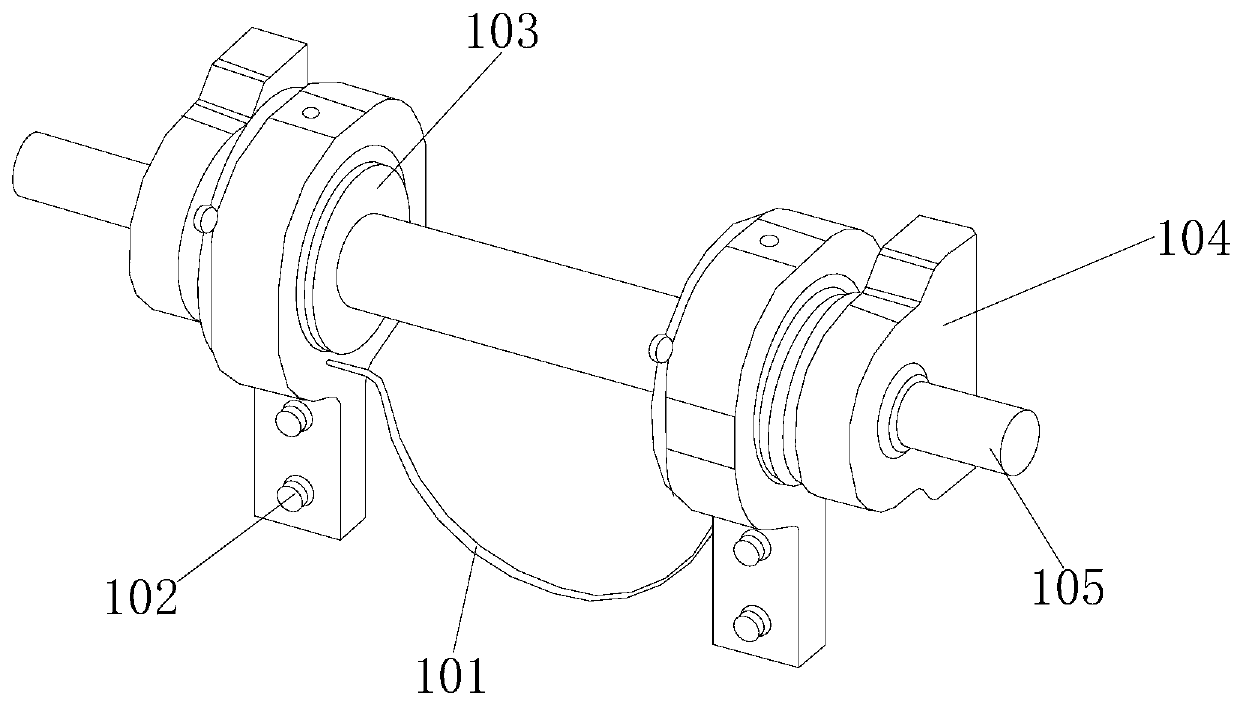

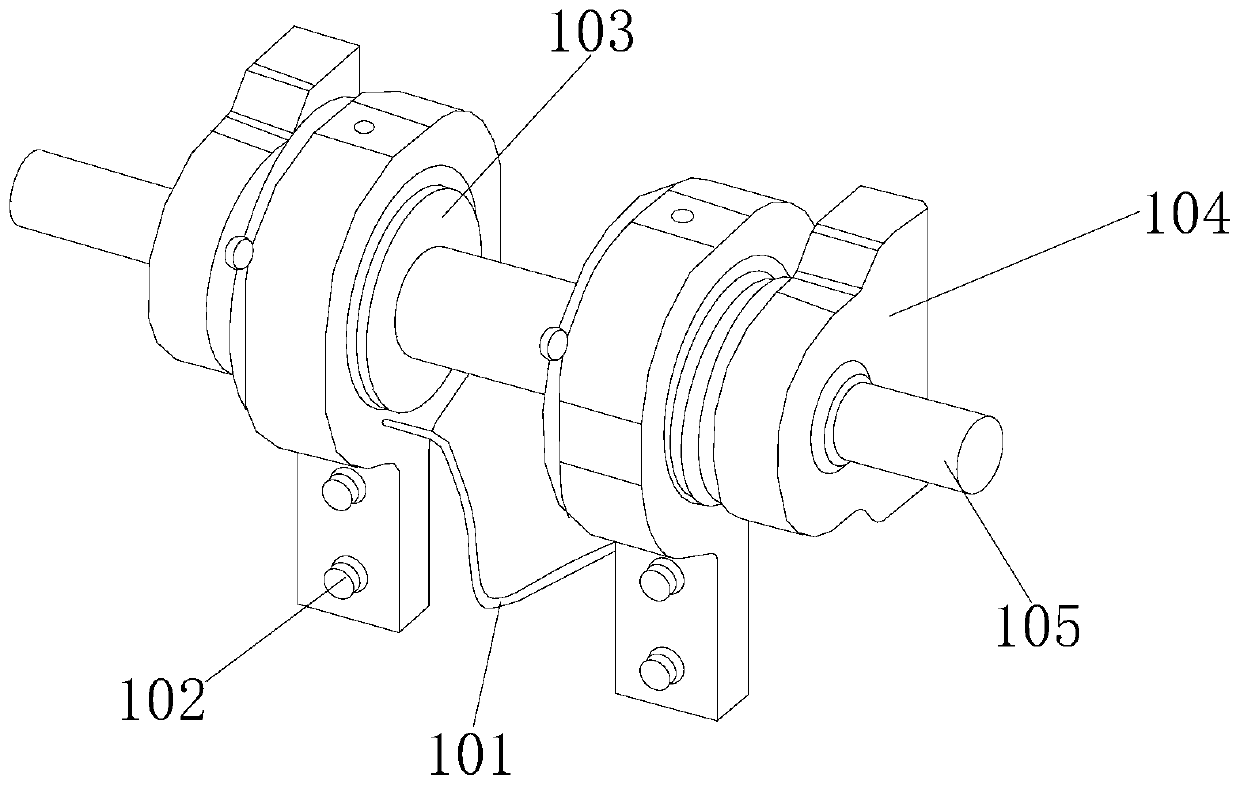

[0032] see Figure 1-Figure 8, the present invention provides a reduction technical solution: a vibration reduction roller type electric two-way tamping machine, its structure includes a fixed frame 1, a sliding rod 2, a sound insulation board 3, a control rod 4, a piston hammer rod 5, a fixed plate 6, Motor 7, muffler 8, driving mechanism 9, adjusting device 10, tamping device 11, described sliding rod 2 is connected on fixed frame 1 by lower end slide block and carries out forward and backward movement, described sliding rod 2 tops and fixed plate 6 Connected in a penetrating manner, the sliding rod 2 is arranged on the left and right sides of the sound insulation board 3, the left side of the sound insulation board 3 is provided with a control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com