Connecting rod type composite adjusting mechanism for angle of fan blade

A technology for adjusting mechanisms and fan blades, which is applied in the control of wind engines, machines/engines, and wind engines. It can solve problems such as large transmission friction coefficient, low transmission efficiency, and unsatisfactory control of blade angles, and achieve transmission ratio. Larger, lower failure rate, and convenient daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

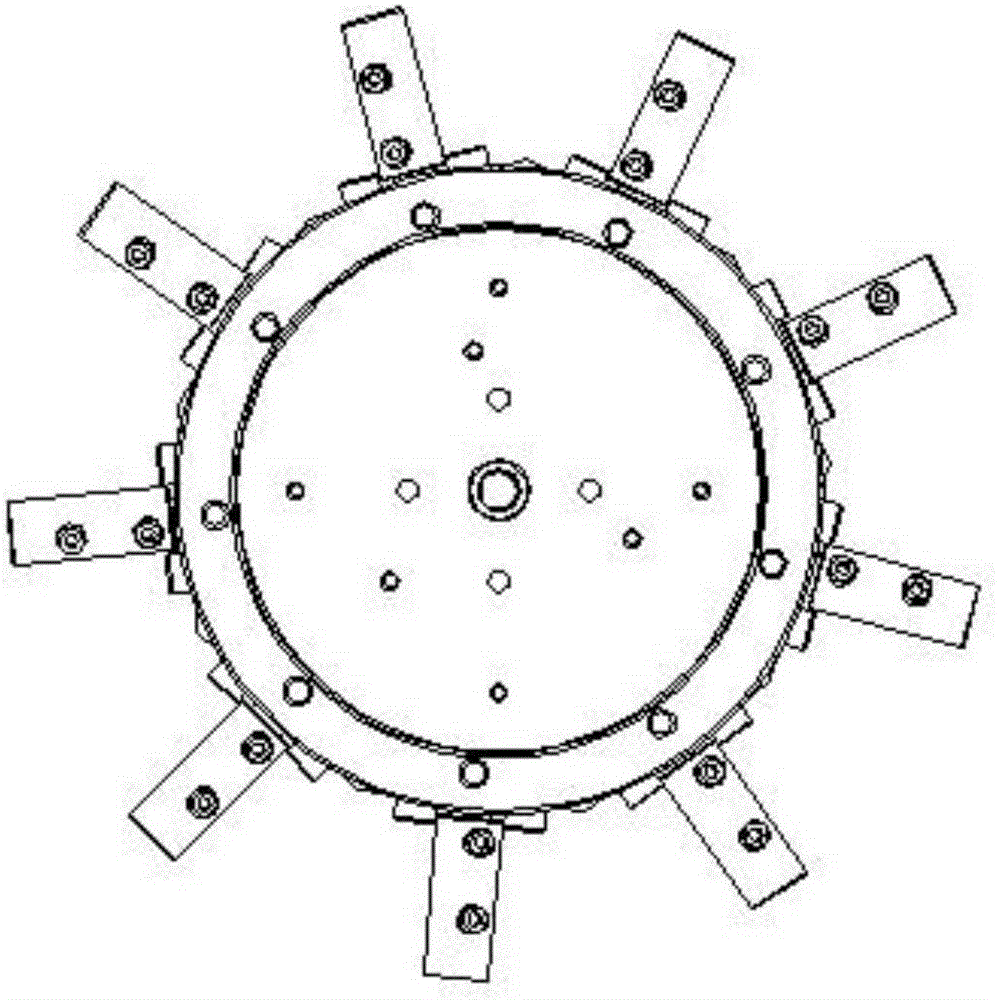

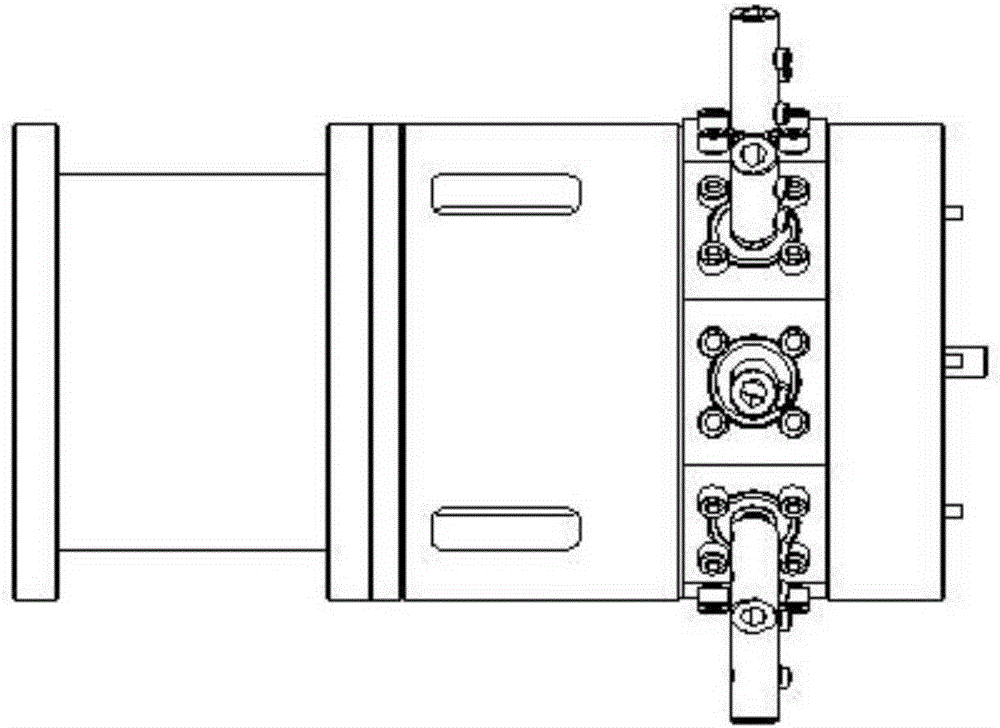

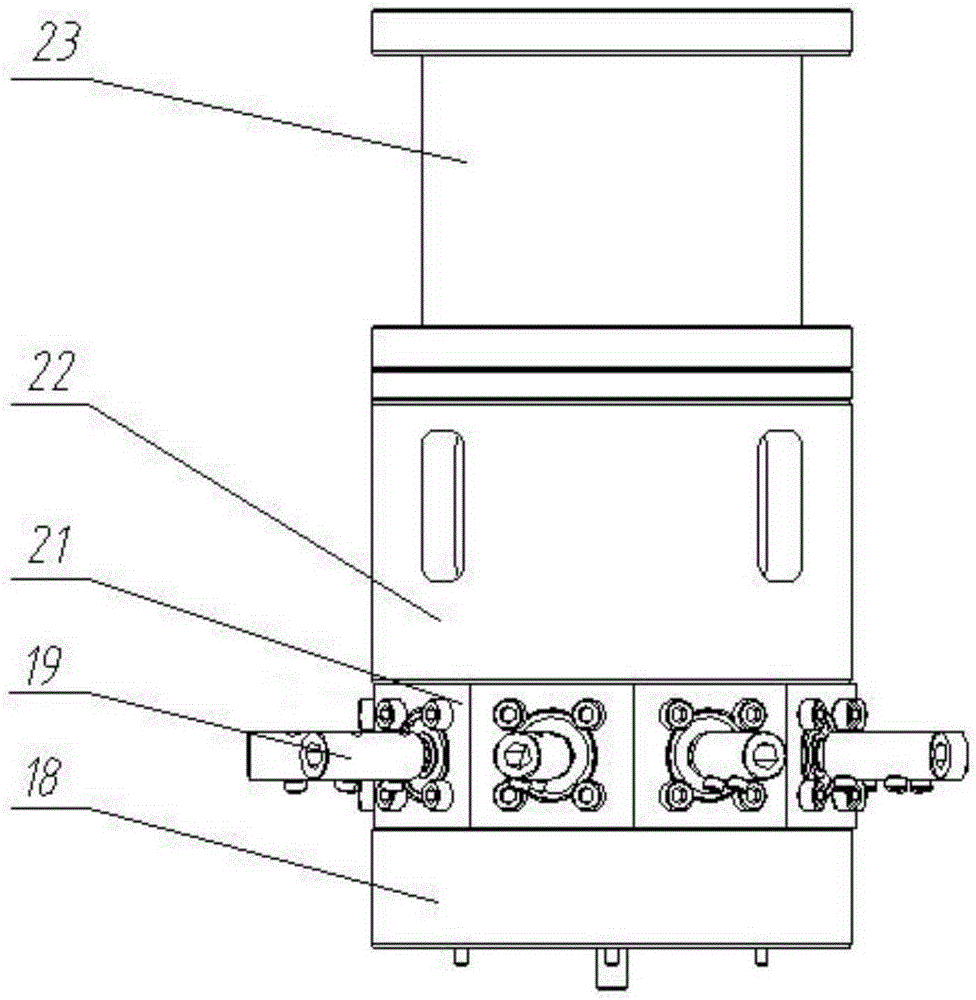

[0029] Depend on Figure 1 to Figure 7 It can be seen that the technical solution of the present invention includes a power unit 17 arranged horizontally on the main shaft, a rear bearing housing 1, a screw 2, a shaft coupling 3, a front bearing housing 4, a nut 5, a sliding rod bearing 6, a sliding disc 7, and a connecting rod 8 , rotating arm 11, transfer shaft 12, slide bar 13, support disc 14, support rod 15, drive motor fixed disc 16, front end cover 18, blade bushing 19, transfer bearing seat 21, cabin cylinder wall 22, machine Seat 23.

[0030] The adjusting mechanism is a link-type composite adjusting mechanism; the power unit 17 for adjusting and controlling the blade angle in this embodiment adopts an electric motor; the cabin cylinder wall 22 of the adjusting mechanism is a circular tube, and the support rod 15 is fixed on the drive motor fixed disk 16 , the support plate 14 is installed on the support rod 15, several slide bars 13 are evenly installed on the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com