A multi-level worm wheel blade adjustment mechanism

A worm gear and adjusting mechanism technology, which is applied to wind turbines, control of wind turbines, engines, etc., can solve problems such as poor synchronization, unsatisfactory power generation cost, and unsatisfactory blade angle control, achieve a large transmission ratio, and improve wind energy utilization. Efficiency and convenient routine maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

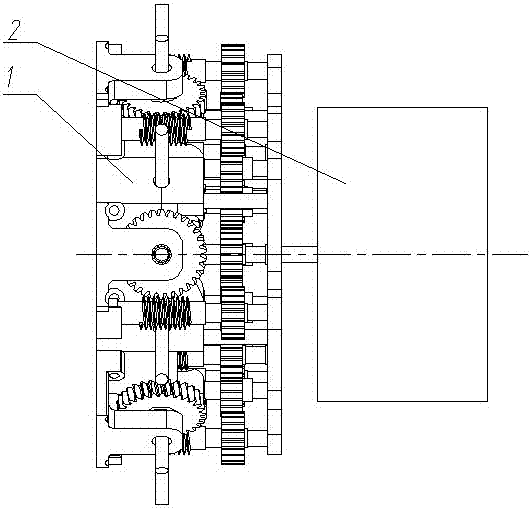

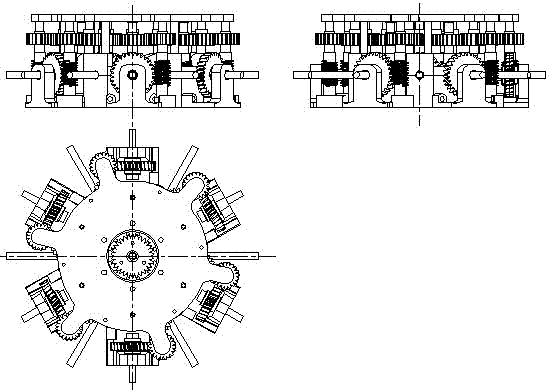

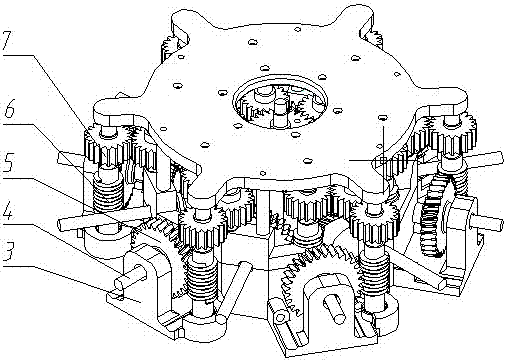

[0018] Depend on Figure 1 to Figure 4 It can be seen that the technical solution of the present invention includes a worm gear seat 8, an outer support frame 3, a blade shaft 4, a cylinder wall 9, a drive motor fixed plate 12, an outer worm wheel 5, an outer worm 6, an inner worm 10, The inner worm gear 13, the main transmission gear 11, and the gear 7; the power unit 2 is placed on the side of the drive motor fixed plate of the adjustment mechanism 1 as a whole;

[0019] The overall adjustment mechanism 1 is a worm gear adjustment mechanism; the power unit 2 for adjusting and controlling the blade angle in this embodiment adopts an electric motor; The transmission gear shaft is located in the center of the inner side of the worm gear seat 8, and the cylindrical wall 9 of the engine room is connected to the fixed plate 12 of the driving motor. There is a hole for assembling the blade shaft 4, the outer support frame 3 is evenly installed on the outside of the worm gear seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com