Connecting rod type wind turbine blade adjusting mechanism and using method

A technology of adjusting mechanism and wind rotor blades, which is applied to wind turbines, wind turbine control, motors, etc., can solve the problems of difficult blade angle control, large blade shaking, poor reliability, etc., to achieve easy adjustment of the angle and reduce production and maintenance. Cost and effect of reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings, but it should be noted that these embodiments do not limit the present invention. Effective transformations or substitutions fall within the protection scope of the present invention.

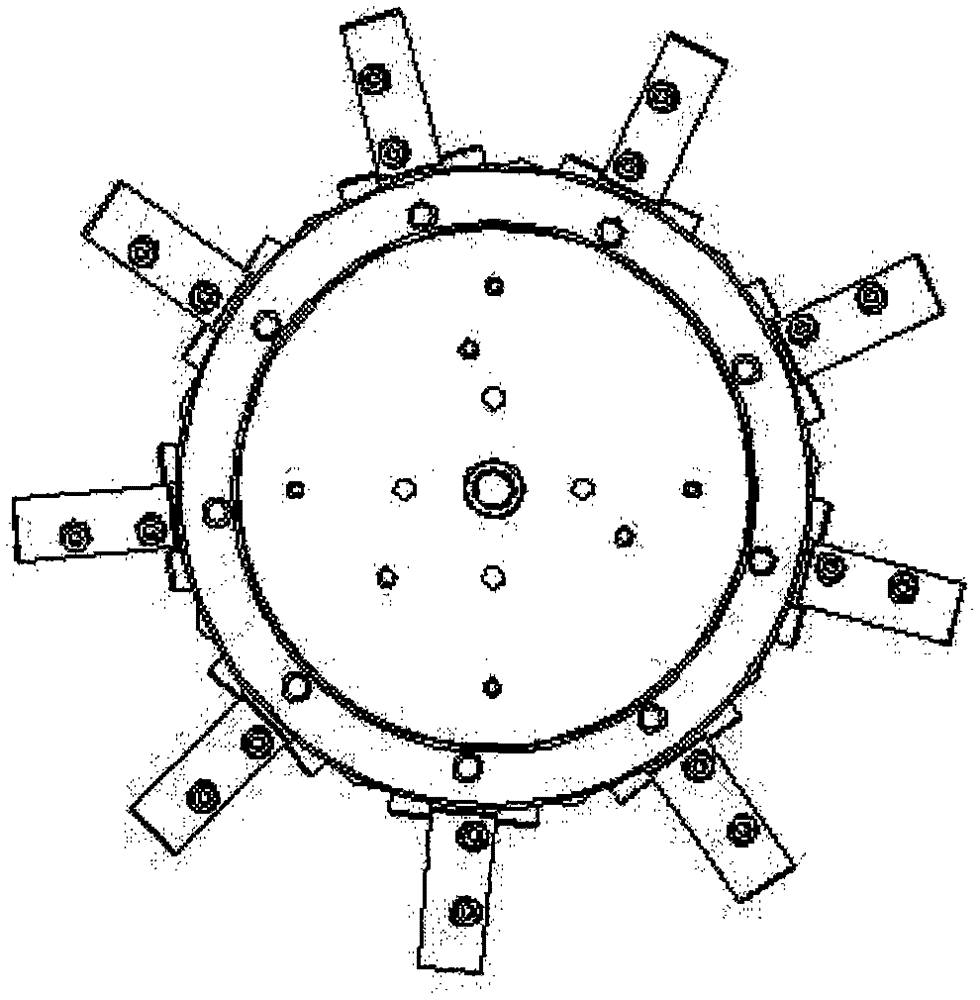

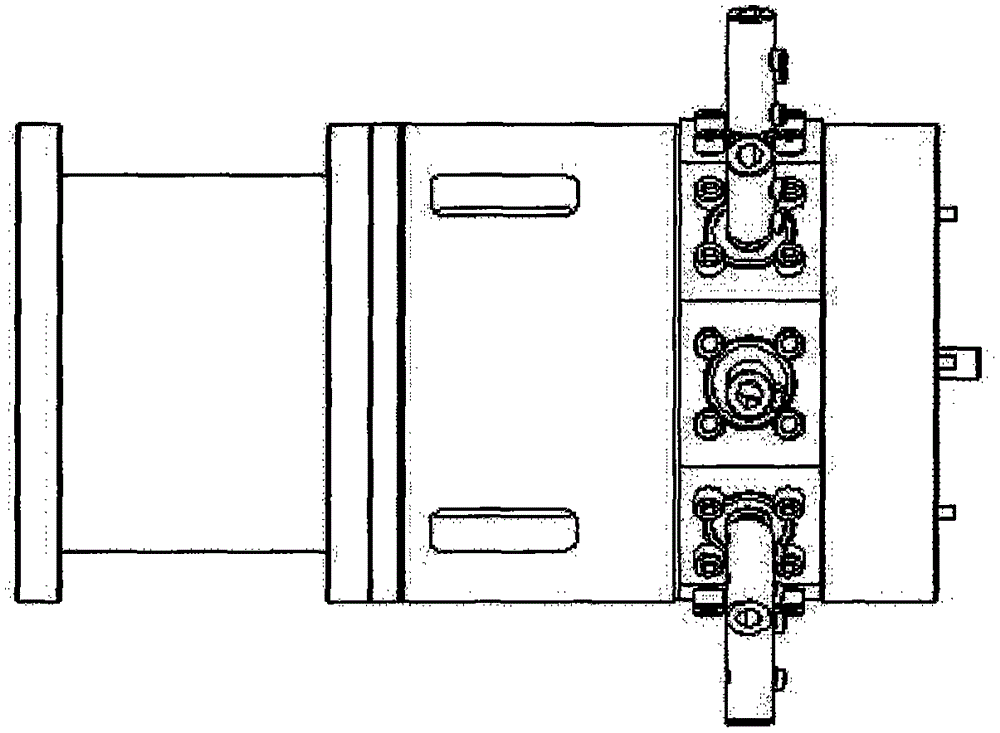

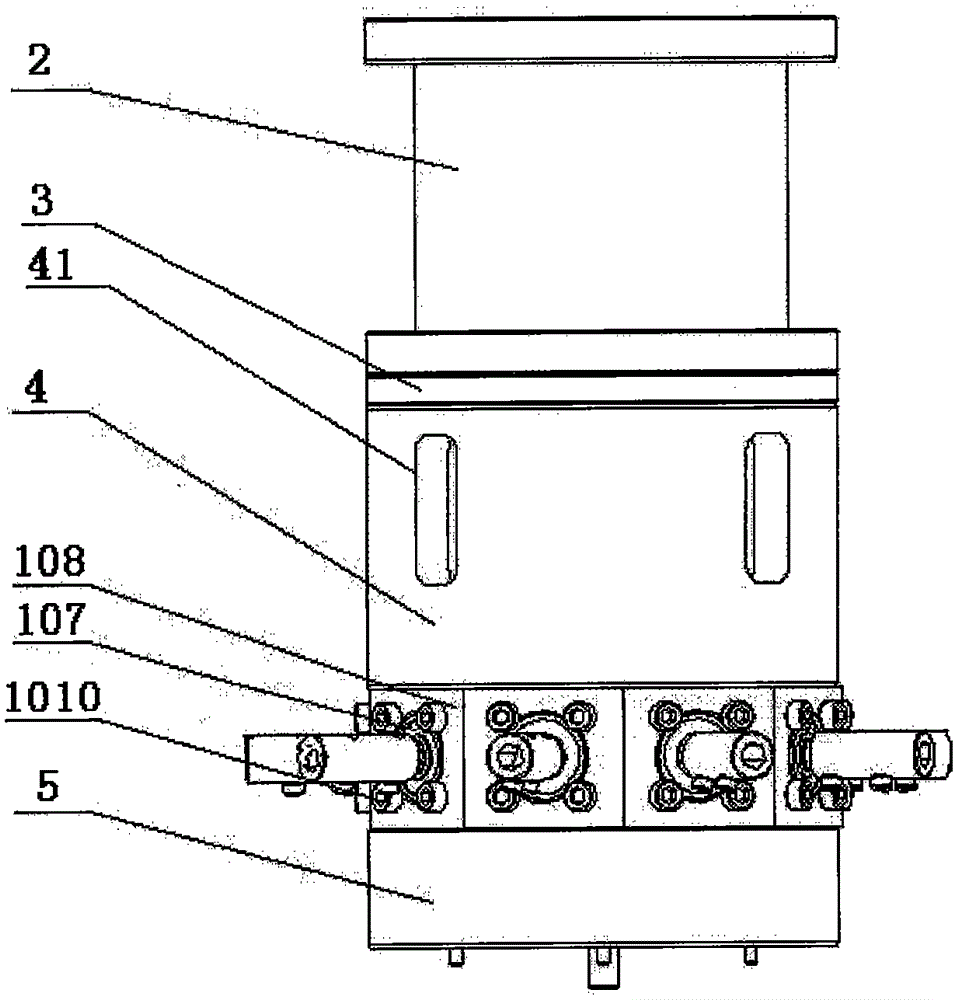

[0028] The present application provides a link-type wind rotor blade adjustment mechanism, which is composed of Figures 1 to 7 It can be known that a link-type wind rotor blade adjustment mechanism includes a power unit 1 with the main shaft horizontally arranged, a machine base 2, a drive motor fixing plate 3, a cabin wall 4, and a front end cover 5. The main shaft is horizontally arranged. The power unit 1 Located inside the base 2, the power unit arranged horizontally by the main shaft is an engine, the base 2 and the cabin wall 4 are connected with the drive motor fixing plate 3 through bolts, and the front end cover 5 is connected with the cabin wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com