Transmission shaft torque calibration method

A calibration method and transmission shaft technology, applied in the field of transmission shaft detection, can solve the problems of troublesome calibration, poor detection accuracy and low reliability of transmission shaft torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

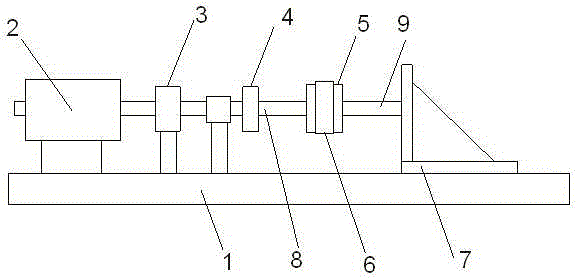

[0029] Example: see figure 1 , a transmission shaft torque calibration method, in the calibration process, a special transmission shaft torque calibration test bench is required, and the test bench includes a base plate 1, a loading motor 2, a torque sensor 3, an angle encoder 4, and a Measure the transmission shaft 5, the strain gauge wireless measurement system 6 and the fixing seat 7. The loading motor 2 is installed on one end of the base plate 1 through the motor base, and the fixing seat 7 is installed on the other end of the base plate 1; during specific implementation, a guide groove is provided on the base plate 1 along its length direction, and the guide groove runs through The bottom plate 1 is far away from the end of the loading motor 2; the fixing seat 7 is connected with the guide groove through a slider, and can be fixed with the bottom plate 1 . The motor shaft of the loading motor 2 is connected to the measuring shaft of the torque sensor 3, and the measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com