Patents

Literature

89results about How to "Avoid Calibration Errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

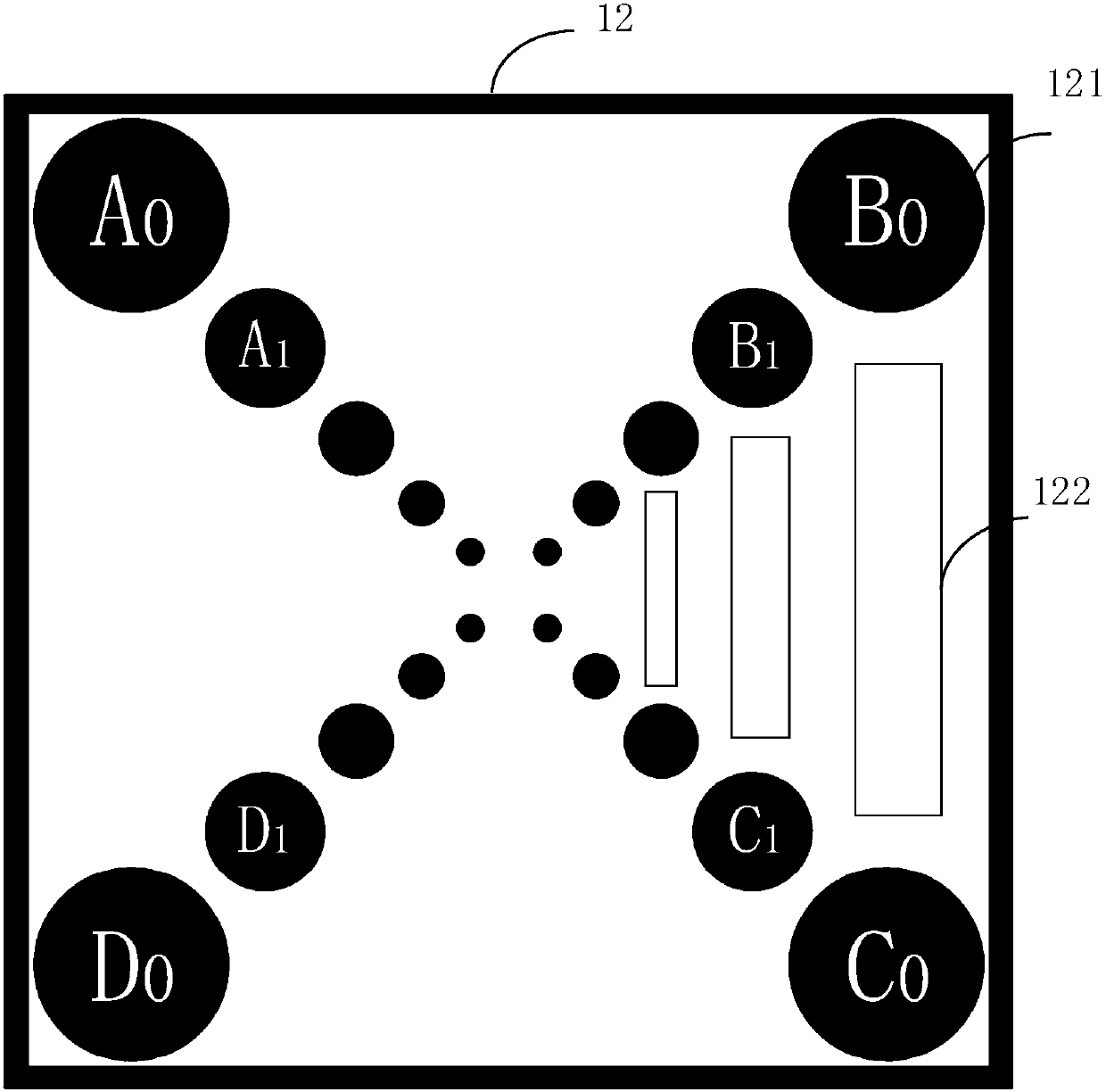

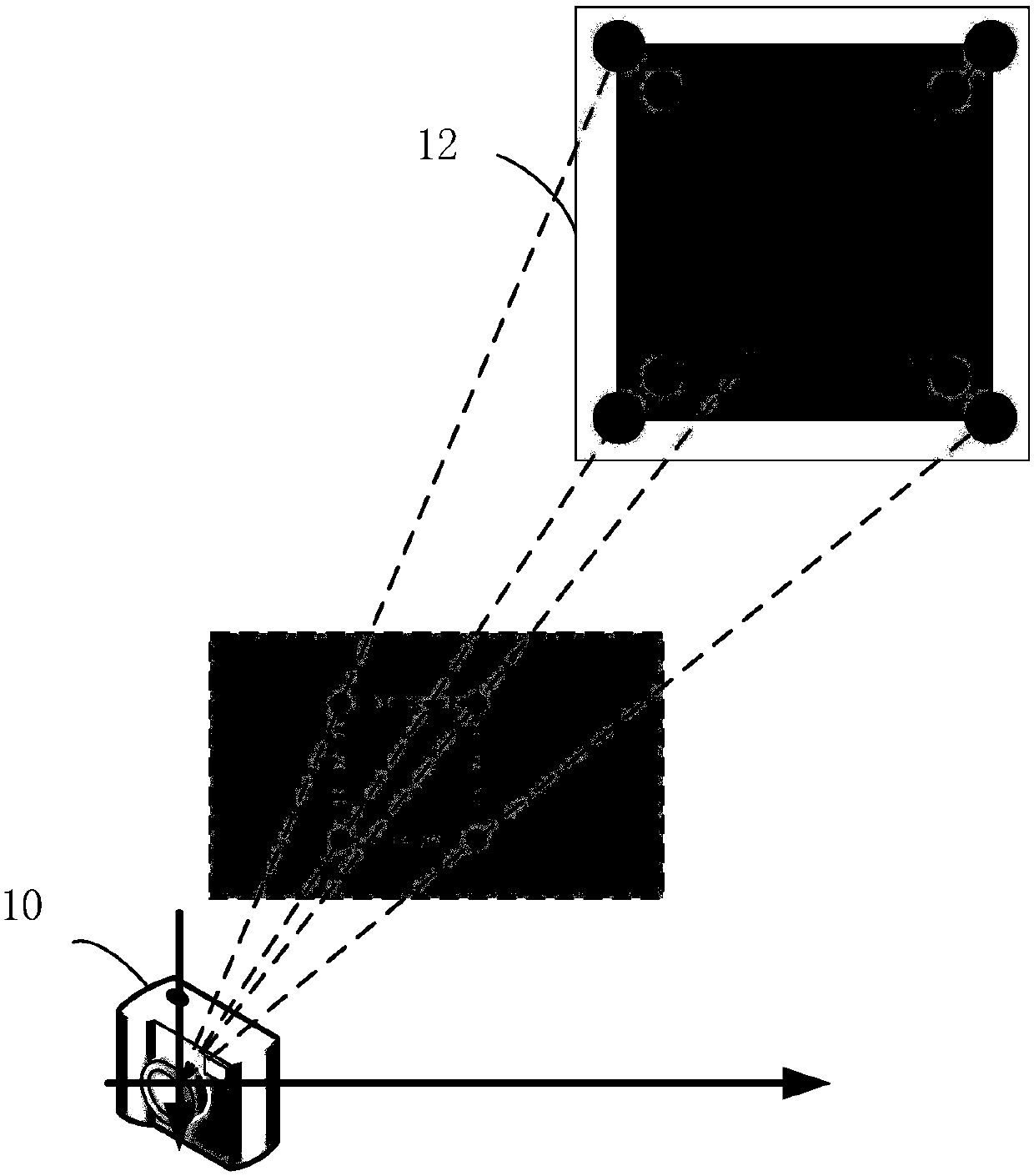

Calibration plate used for binocular camera calibration, calibration method and calibration system thereof

InactiveCN106887023AClear calibrationImprove calibration accuracyImage analysisImage resolutionDisplay device

The invention discloses a calibration plate used for binocular camera calibration and a binocular camera calibration method. In an existing camera calibration method technology, a high precision calibration reference object is difficult to make, cost is high, operation is complex and tedious, calibration precision is not high and so on. By using the calibration plate and the method, the above problems are solved. The calibration plate used for binocular camera calibration comprises an electronic equipment terminal machine and a display, wherein the electronic equipment terminal machine is used for receiving resolution information and outputting plane checkerboard image driving information according to a resolution; and the display is used for receiving the plane checkerboard image driving information and displaying a plane checkerboard image.

Owner:CHENGDU TOPPLUSVISION TECH CO LTD

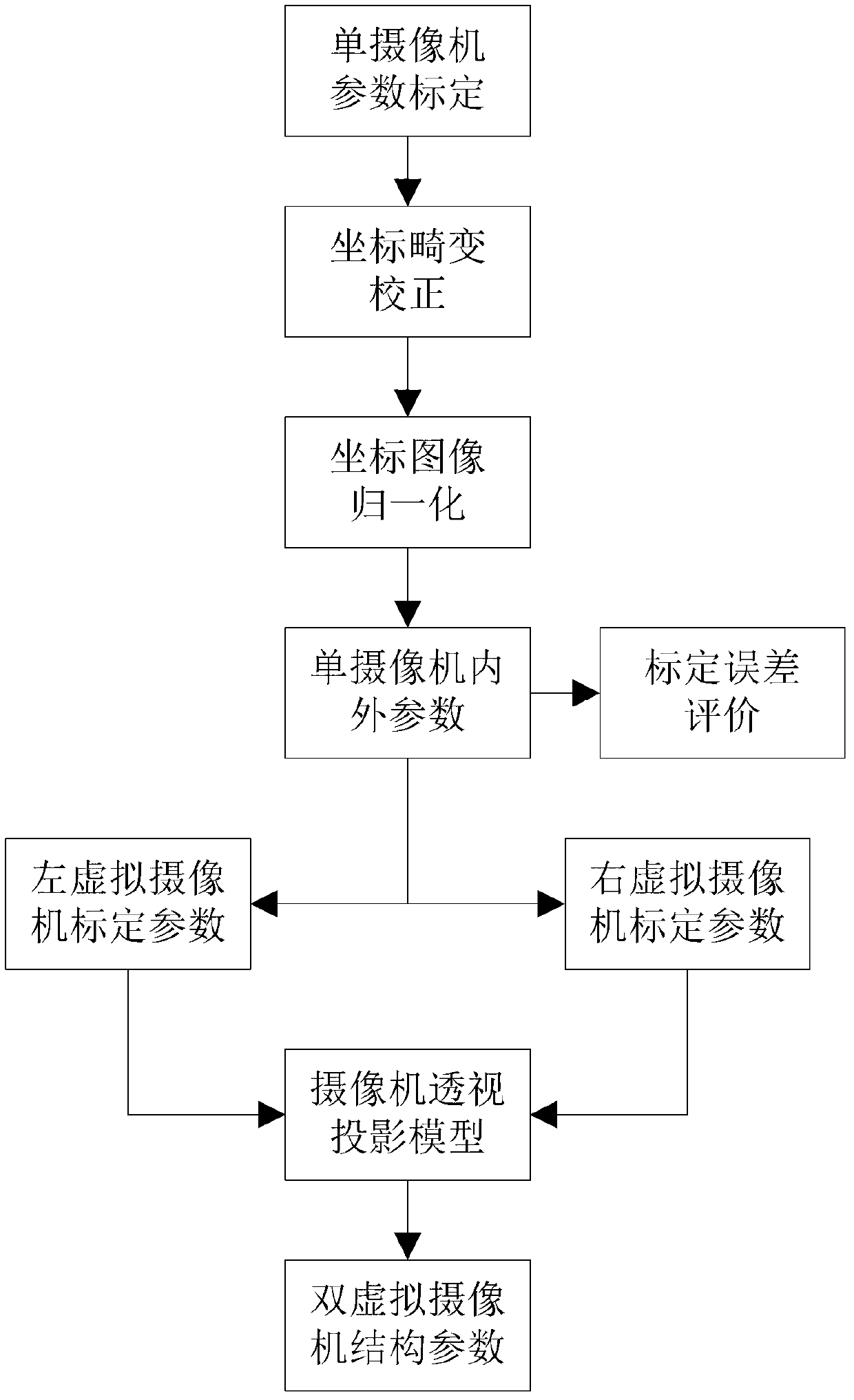

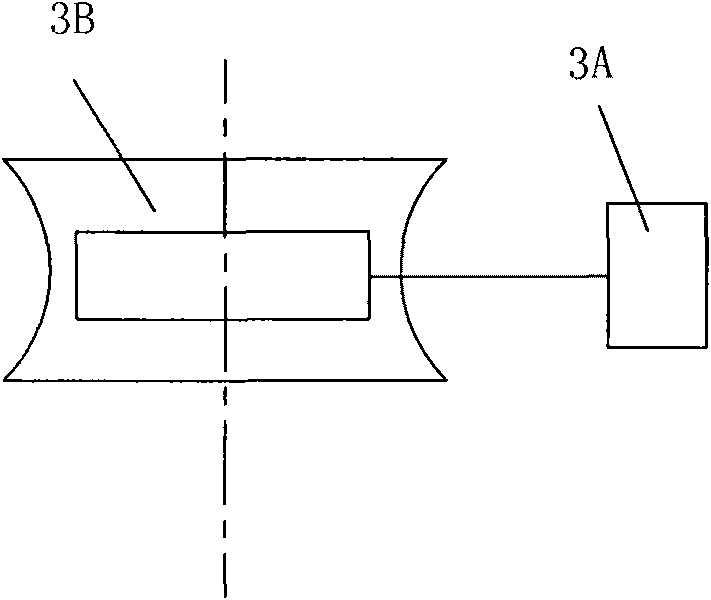

Variable-focus monocular and binocular vision sensing device

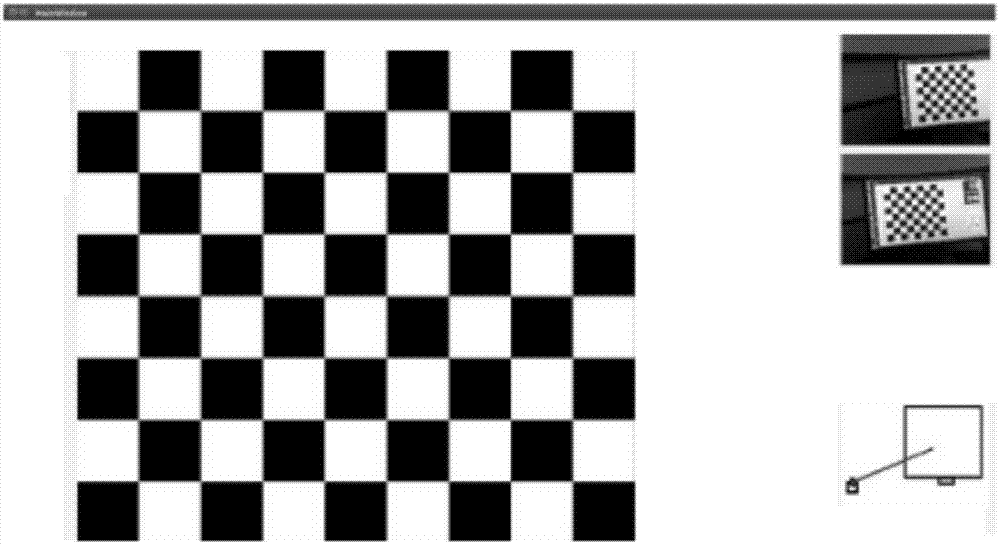

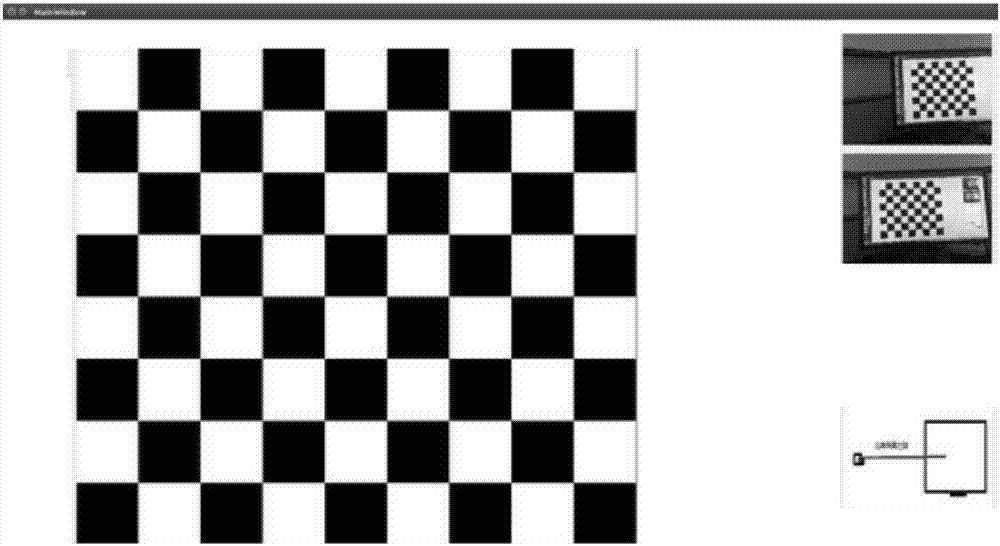

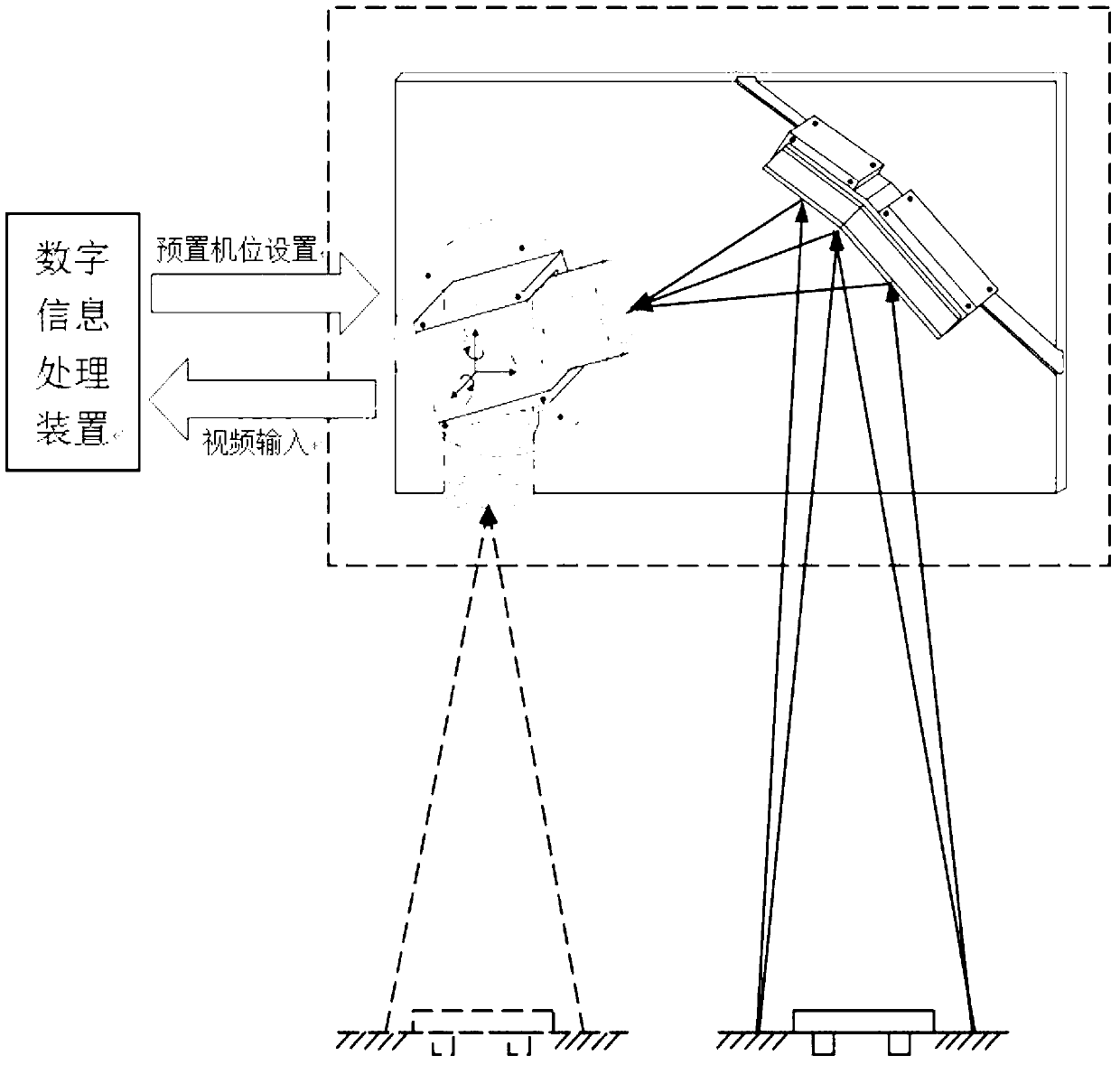

ActiveCN103278139AAchieve visual effectsRealize the measurement functionPhotogrammetry/videogrammetryInformation processingMirror image

The invention provides a variable-focus monocular and binocular vision sensing device comprising a mirror image type optical system, a high-precision bearing holder, an image acquisition system, a digital information processing device and other parts. The variable-focus monocular and binocular vision sensing device can guarantee that a variable-focus image sensor (a CCD (Charge Coupled Device) or an analog video camera) mounted on the high-precision bearing holder can be accurately located at a certain required monocular vision preset station, and can automatically regulate the focus to the required value so as to perform monocular vision measurement or guidance work; the variable-focus monocular and binocular vision sensing device also can accurately locate the image sensor at the unique determined binocular vision preset station, and can automatically regulate focus to the required value, and thus, the image sensor and the mirror image type optical system jointly form a binocular vision sensing system, and sequentially, the function of binocular vision guidance or measurement is realized; and moreover, the variable-focus monocular and binocular vision sensing device can realize automatic switching between a monocular vision station and a binocular vision station through programming of the digital information processing device according to the task requirements, so as to realize the functions such as monocular and binocular vision measurement, guidance or obstacle avoidance.

Owner:BEIHANG UNIV

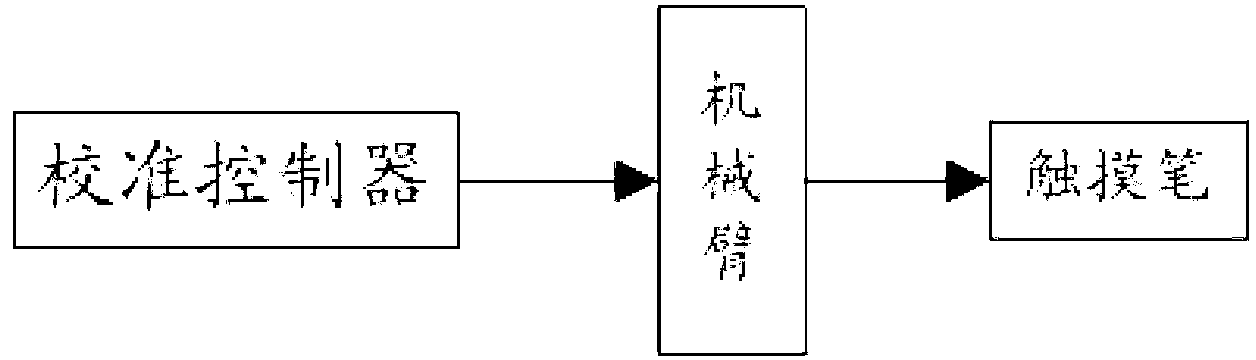

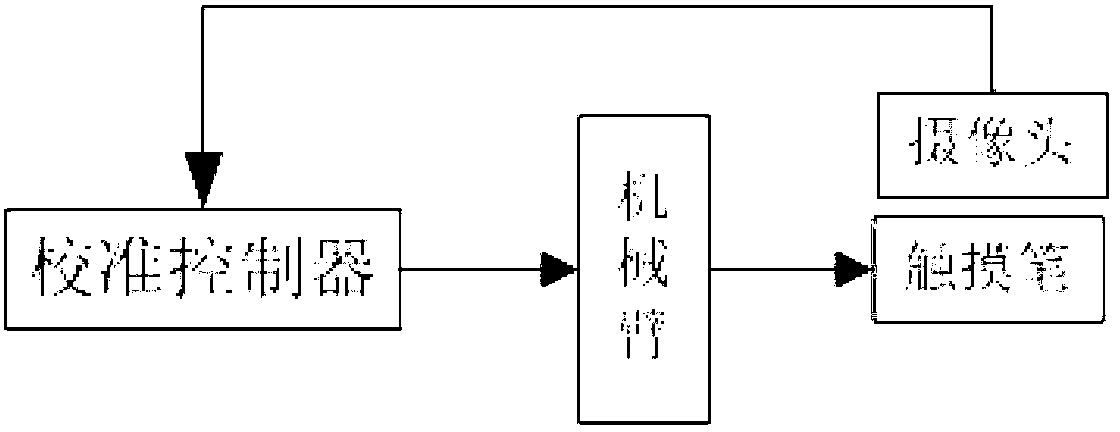

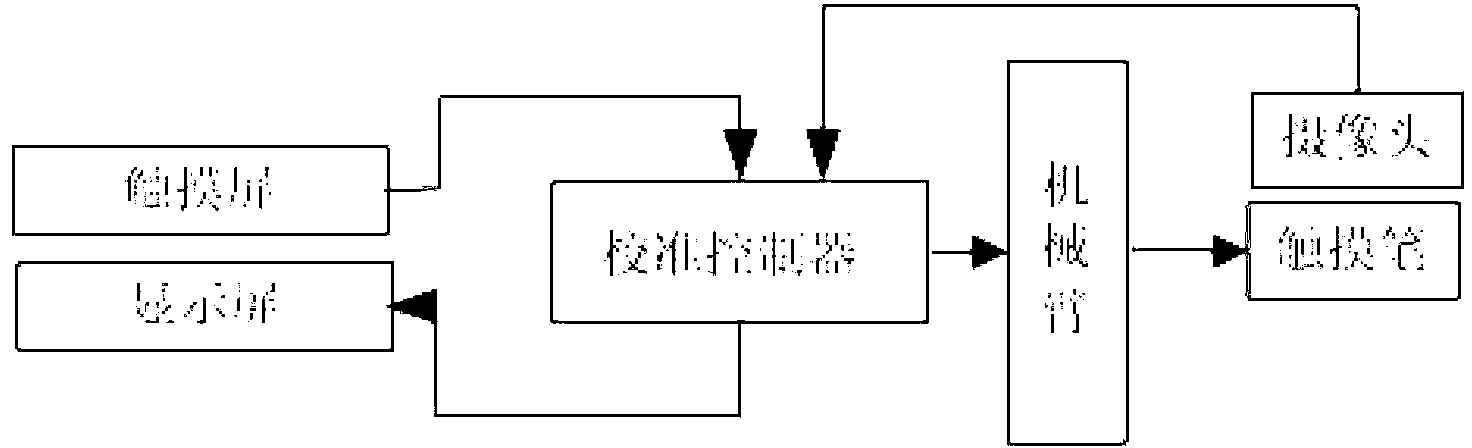

Positioning clicking device and method and touch display screen calibration system and method

InactiveCN103235661AHigh precisionEliminate errorsInput/output processes for data processingAutomatic controlHuman–computer interaction

The invention relates to a positioning clicking device and method and a touch display screen calibration system and method. The positioning clicking device automatically controls a mechanical arm to drive a touch pen to click the center of a calibration point displayed on a display screen to be tested through a calibration controller, and the whole positioning clicking process is automatic, needs no manual intervention and is high in execution efficiency. In addition, compared with manual operation, the positioning clicking device has higher accuracy in calibration point clicking. Therefore, by adopting the calibration system comprising the positioning clicking device and the touch display screen calibration method by using the calibration system, accurate touch point coordinates and calibration parameters can be obtained, errors of a display zone and a touch zone caused by mechanical assembling are removed by aid of the calibration system, touch accuracy is improved, and mistaken touch is effectively avoided.

Owner:BEIJING UNITOP NEW TECH CO LTD

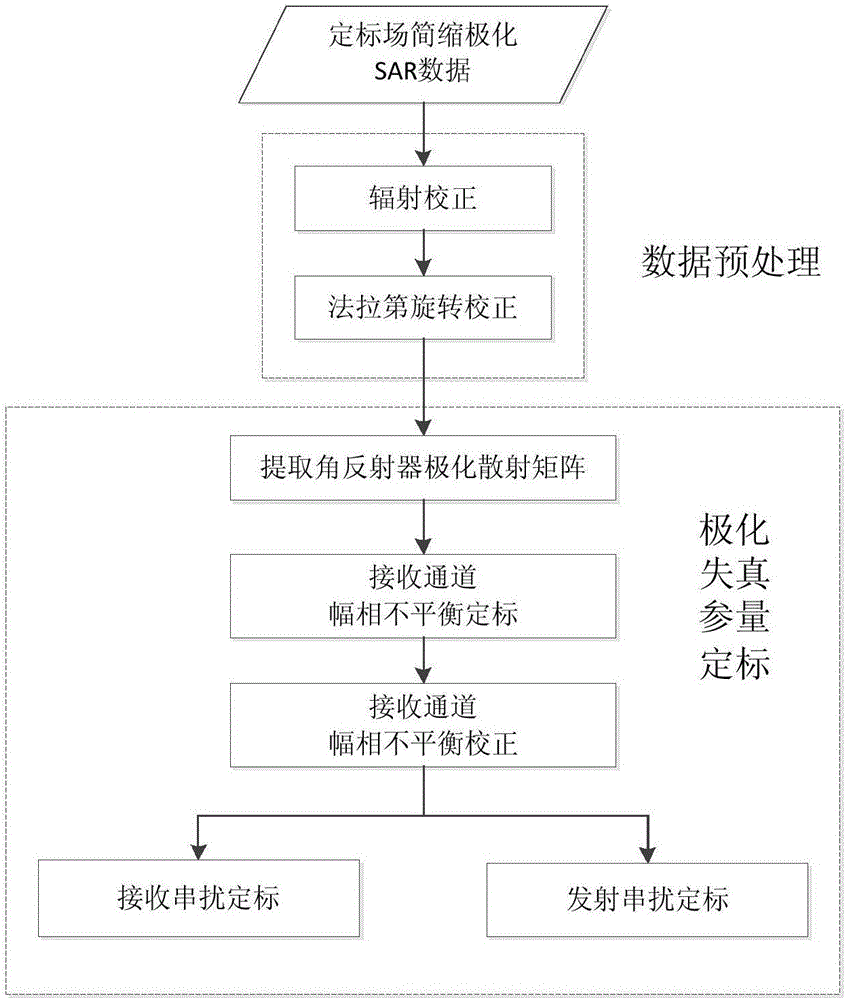

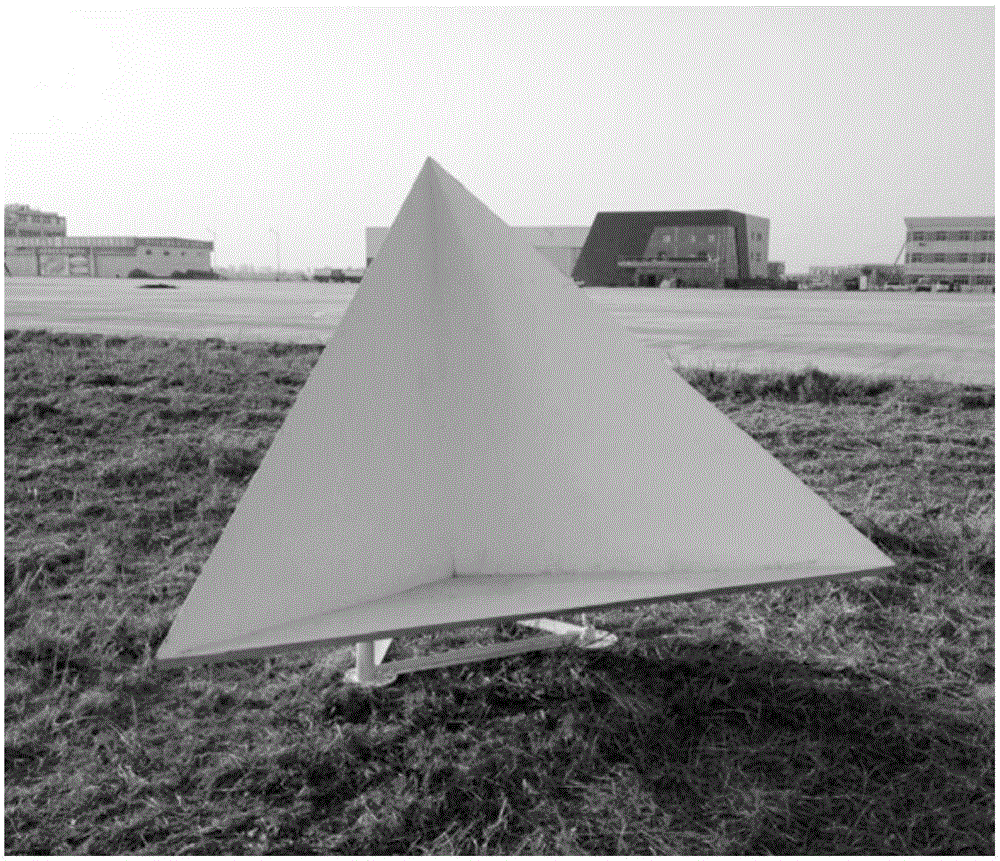

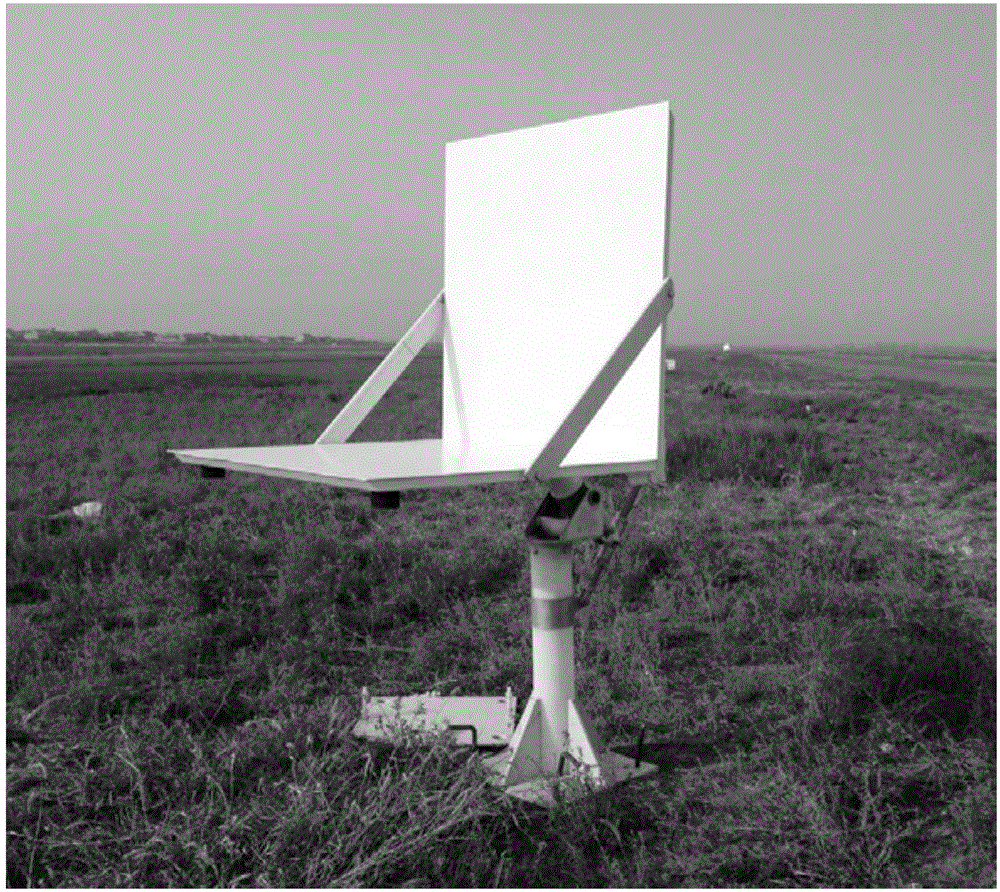

Multi-polarization SAR compact polarimetry calibration method

ActiveCN106405547AReduce weightSimplify requirementsRadio wave reradiation/reflectionPolarimetric sarCalibration algorithm

The invention provides a multi-polarization SAR compact polarimetry calibration method which comprises a calibration field compact polarimetry SAR data preprocessing process and a polarization distortion parameter calibration process. In the calibration field compact polarimetry SAR data preprocessing process, compact polarimetry SAR data radiation correction and Faraday rotation correction are mainly completed. In the polarization distortion parameter calibration process, four different types of common corner reflectors are used as reference calibrators, and a compact polarimetry calibration method (namely, a compact polarimetry polarization distortion parameter calibration method) is deduced based on a calibration model. Through the method, a polarization distortion parameter can be calibrated precisely. The calibration algorithm does not depend on the absolute RCS values of the corner reflectors, and calibration error caused by RCS inconsistency of different corner reflectors can be avoided effectively. The algorithm is of high robustness and practicability.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

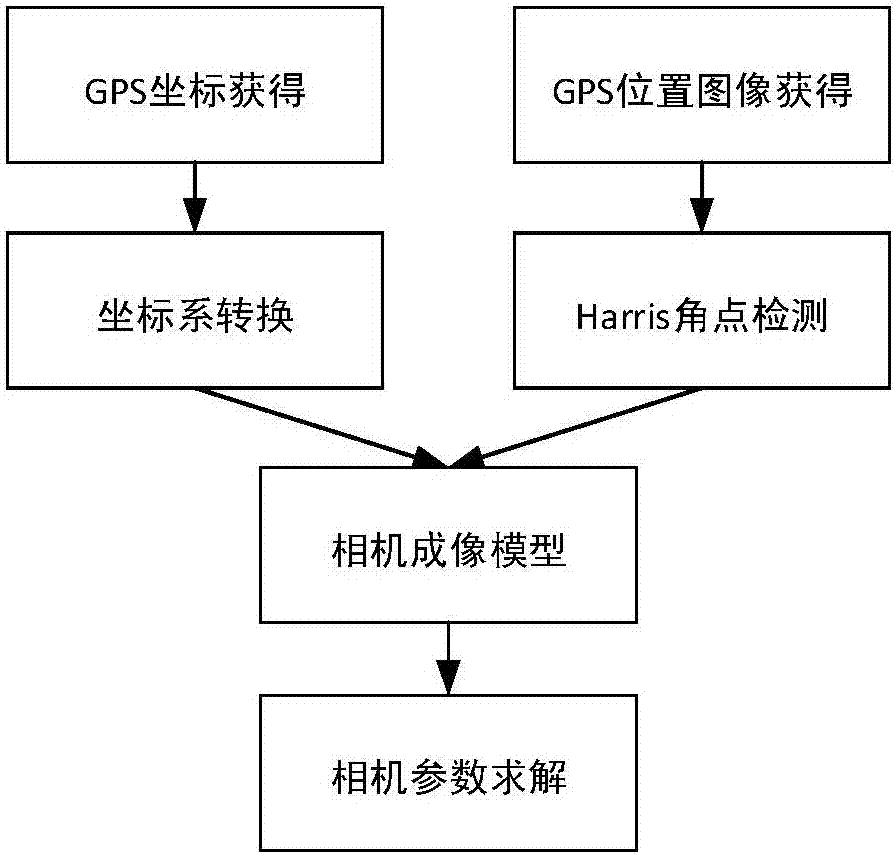

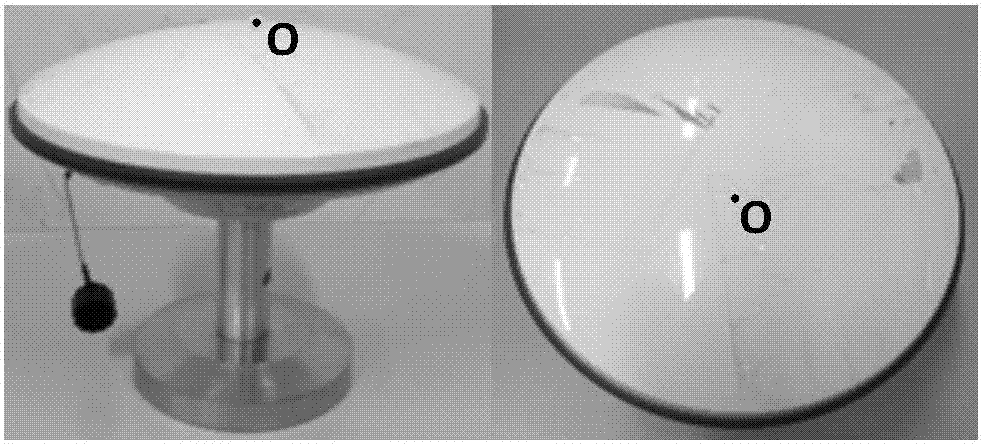

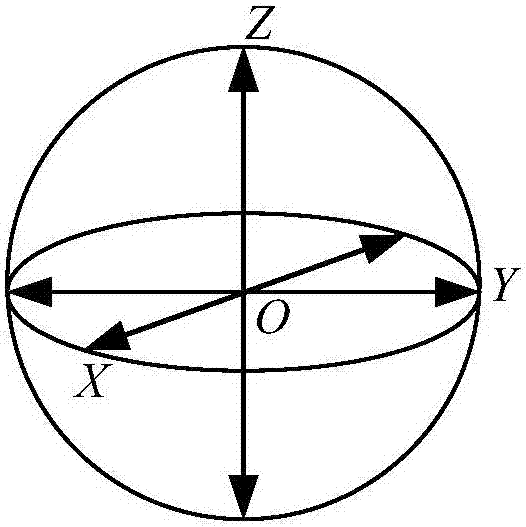

Camera parameter calibration method based on GPS

InactiveCN107464264AAvoid low precisionImprove accuracy and precisionImage analysisSatellite radio beaconingGps navigationEnvironmental geology

The invention proposes a camera parameter calibration method based on a GPS, and the method comprises the steps: obtaining the longitude, latitude and height coordinates of the mass center of a GPS receiving antenna in a GPS navigation coordinate system through a GPS receiving antenna, and collecting images of the GPS receiving antenna at different positions through a camera; carrying out the coordinate conversion according to the GPS navigation coordinate system and the world coordinate system, obtaining the coordinates of the mass center of the GPS receiving antenna, and obtaining the coordinates of the mass center of the GPS receiving antenna in the images through employing a Harris corner detection algorithm; and solving a camera parameter matrix according to a camera imaging model. According to the invention, the method employs the precise coordinates of the GPS to replace a calibration template in a calibration process, avoids a calibration error caused by low precision of the calibration template, and improves the calibration precision.

Owner:NANJING UNIV OF SCI & TECH

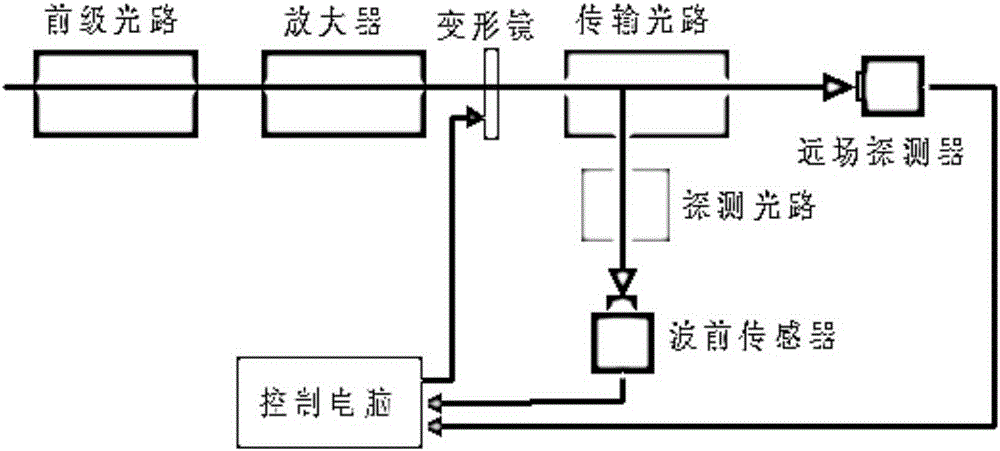

Laser beam wavefront correction system and method

InactiveCN105223688AReduce complexityReduce the difficulty of debuggingOptical elementsWavefront sensorClosed loop

The invention provides a laser beam wavefront correction system, comprising a main laser path, a deformable mirror and a high-voltage driver, a far-field detector, a wavefront sensor, a detection light path and a control computer. A far-field sensor and the wavefront sensor can precisely realize wavefront correction of a whole light beam only by utilizing main laser of a laser system. The laser beam wavefront correction method provided by the invention uses a far-field information feedback algorithm to perform closed-loop control on static wavefront distortion, through a reference transition transfer technology, transits a static wavefront to the wavefront sensor, then performs dynamic emission, collects dynamic waveform, and finally controls the deformable mirror to realize wavefront correction of a whole system. The method is advantaged by being capable of effectively avoiding the problem of wavefront detection and calibration in a small-F-number focusing system, lowering a requirement for system debugging precision, not needing to add an extra calibration light source, and being capable of precisely realizing effective control of to-target wavefront distortion of the whole system.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

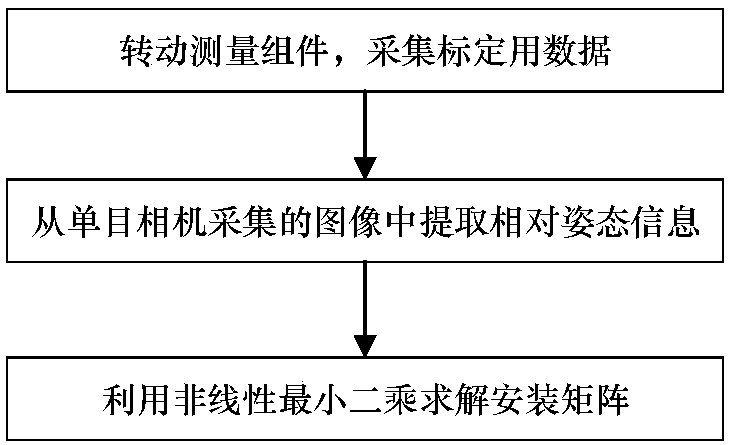

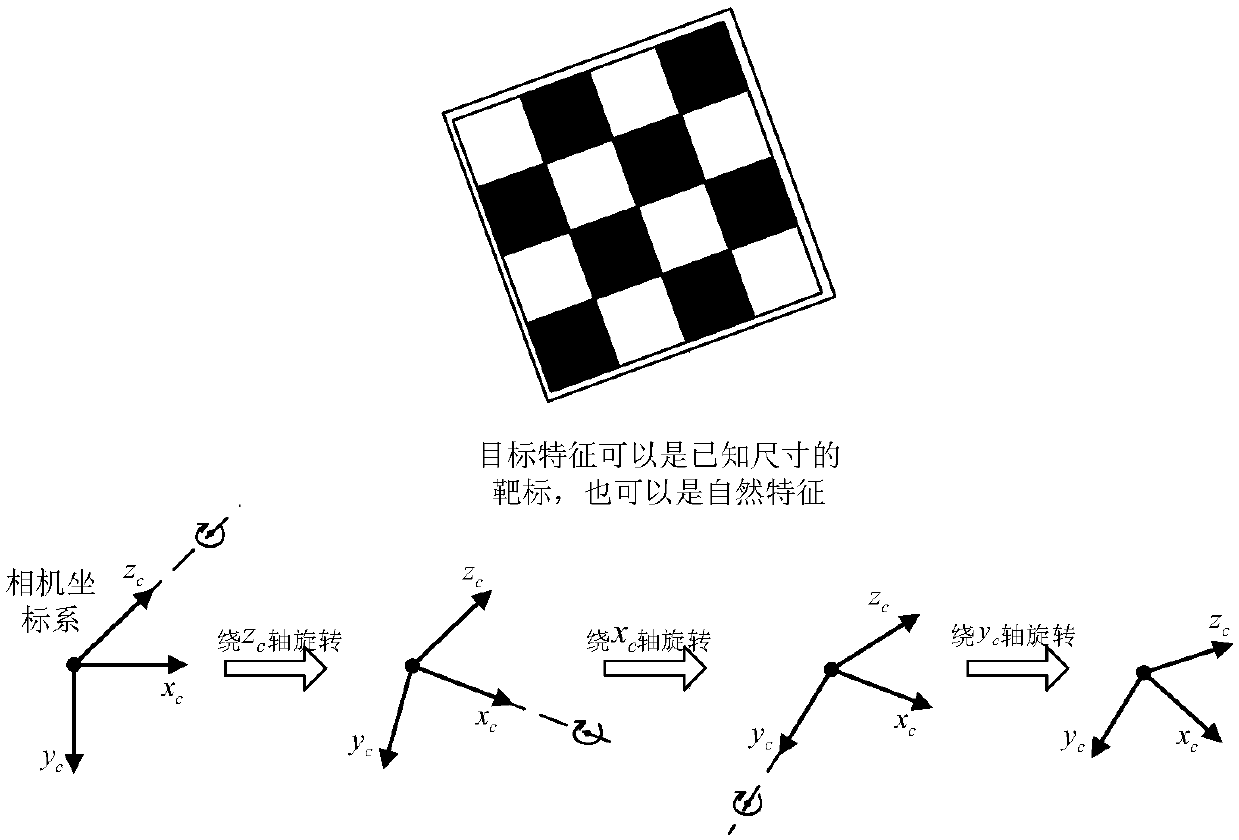

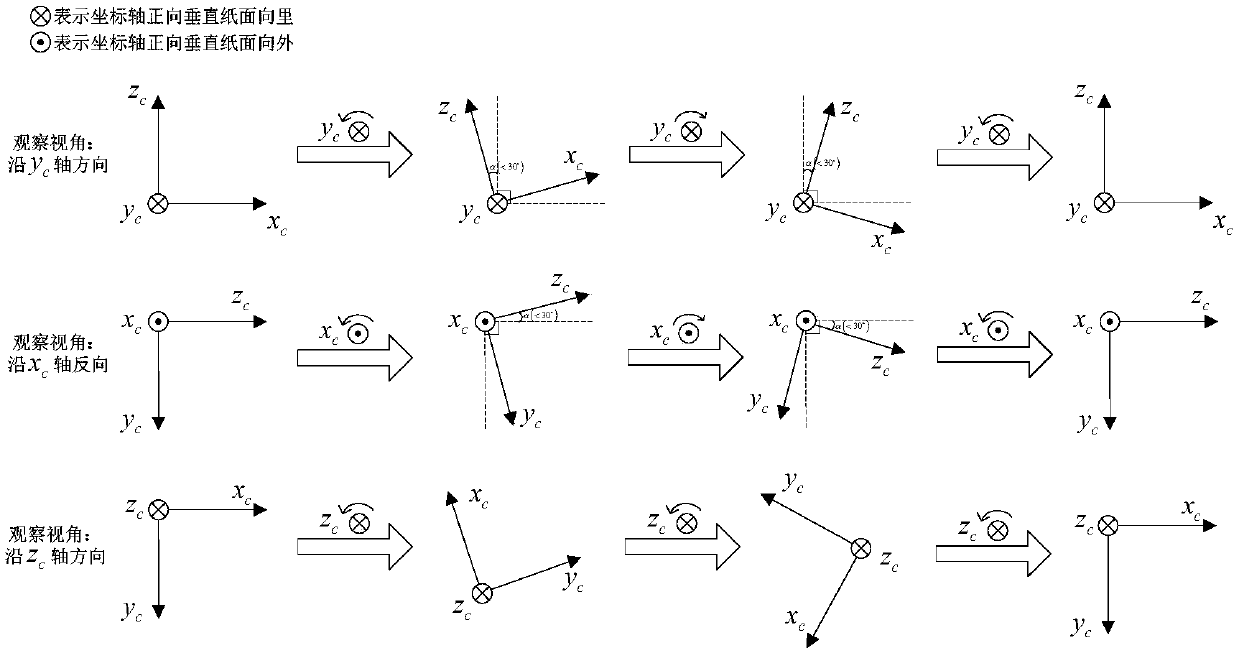

Monocular camera and inertial measurement unit relative mounting angle calibrating method

ActiveCN108592950AAvoid Calibration ErrorsReduce preparation timeMeasurement devicesData collectingNon-linear least squares

The invention discloses a monocular camera and inertial measurement unit relative mounting angle calibrating method and belongs to the field of sensor calibration. The method comprises the following steps of, firstly, rotating a measurement module to collect calibrating data, wherein the measurement module is composed of a monocular camera and an inertial measurement unit; secondly, extracting relative attitude information from images collected by the monocular camera; thirdly, solving a mounting matrix through a nonlinear least square method. With dependence on absolute reference information,the monocular camera and inertial measurement unit relative mounting angle calibrating method can avoid calibrating errors resulting from absolute reference information measurement errors; besides, during the calibrating process, the data collecting period is short and the calibrating precision is high, so that the monocular camera and inertial measurement unit relative mounting angle calibratingmethod can meet the requirements of combined configuration of the monocular camera and the inertia measurement unit on spatial alignment during practical application.

Owner:BEIHANG UNIV

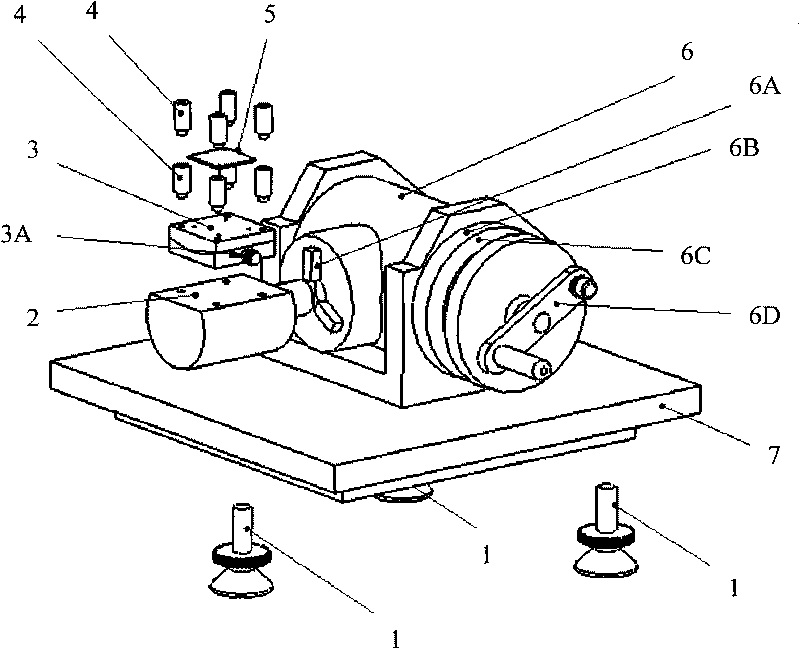

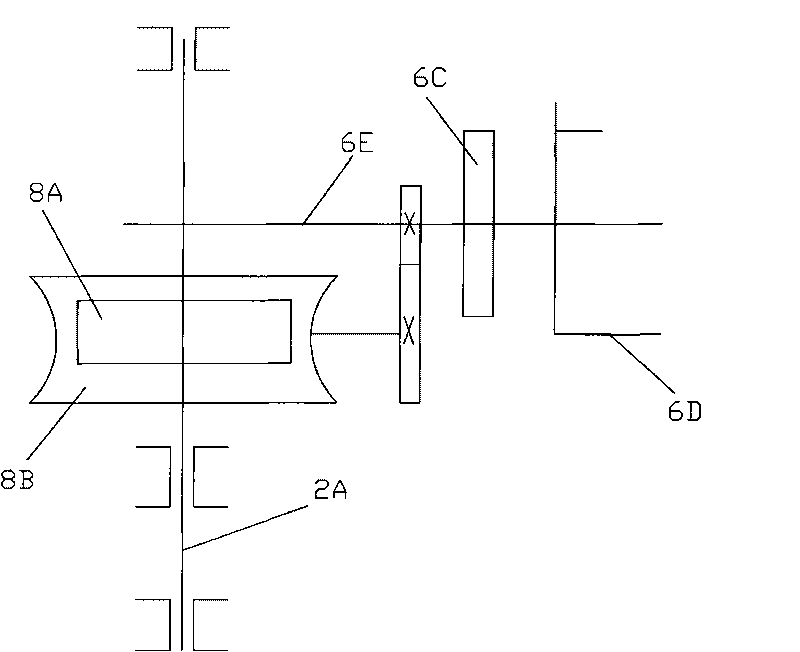

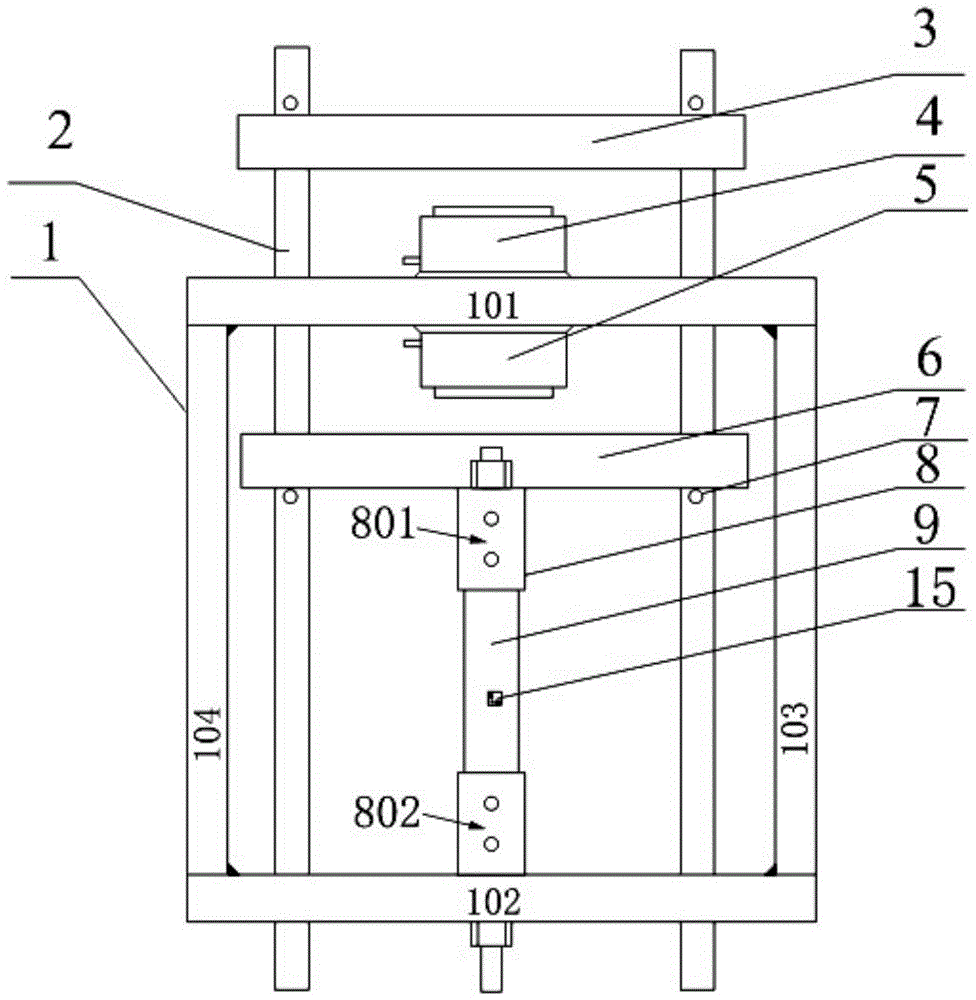

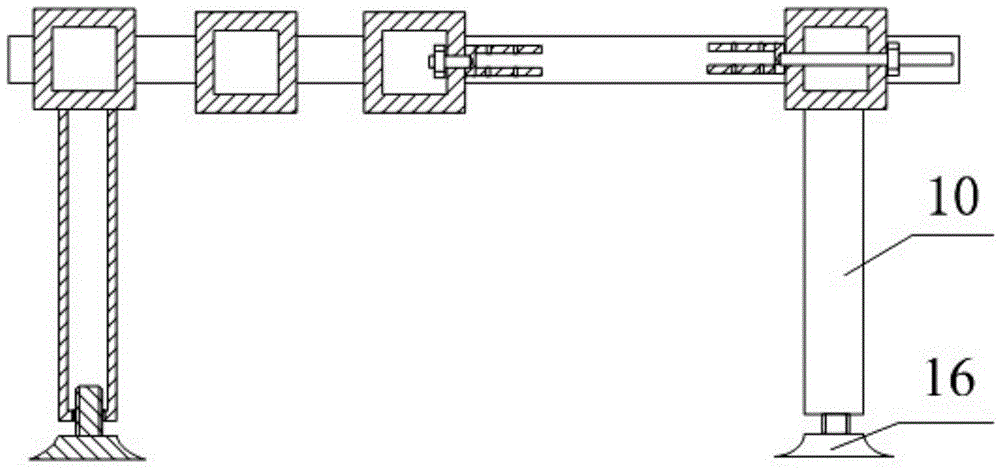

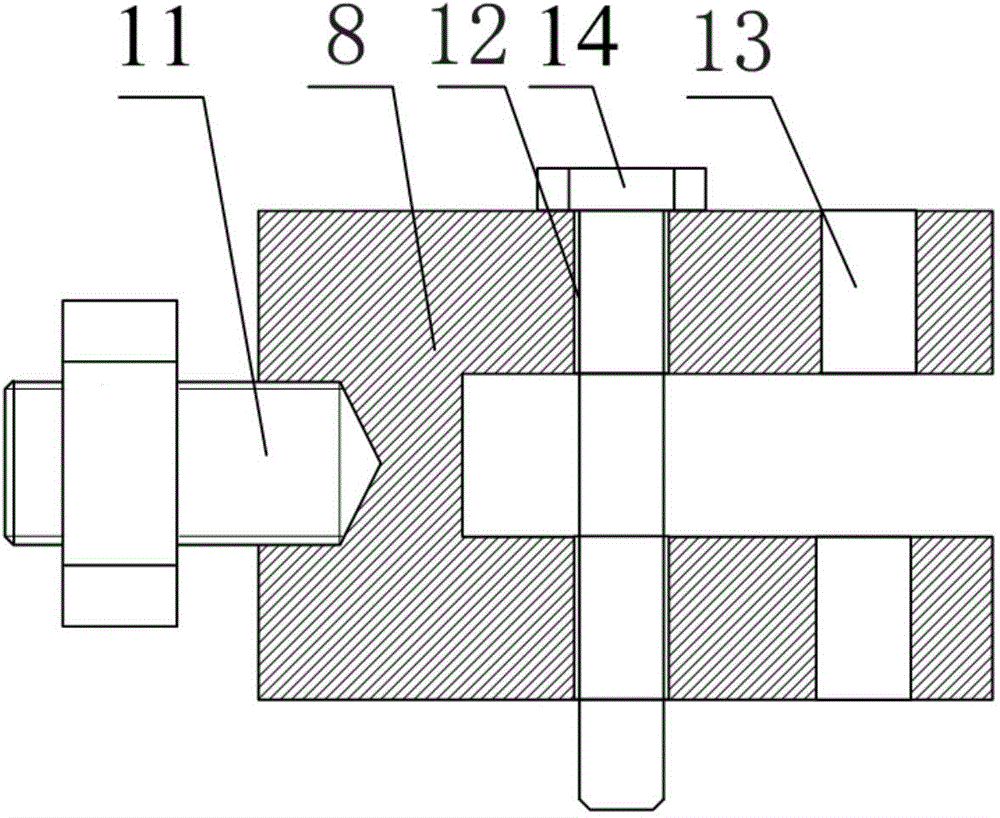

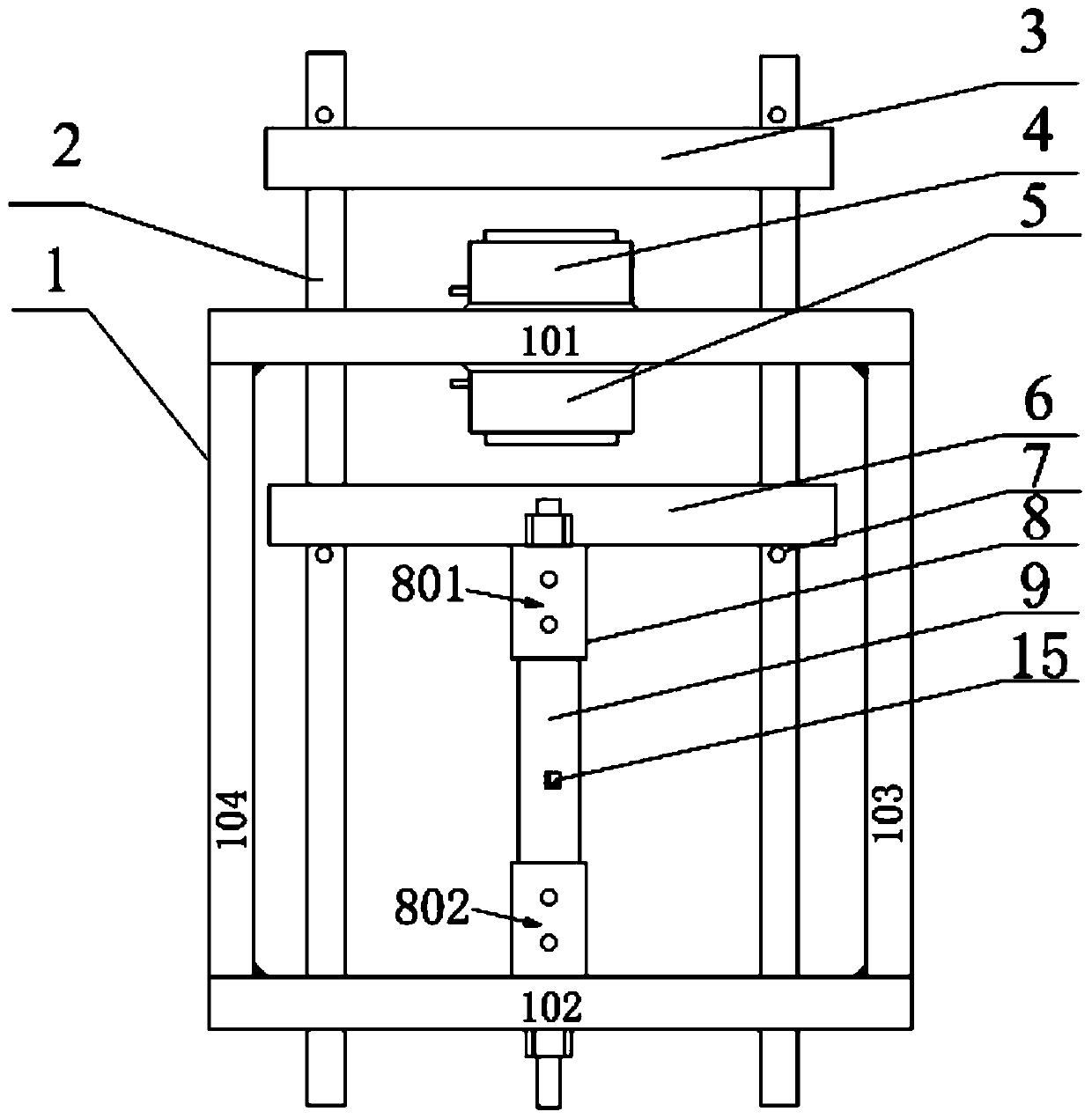

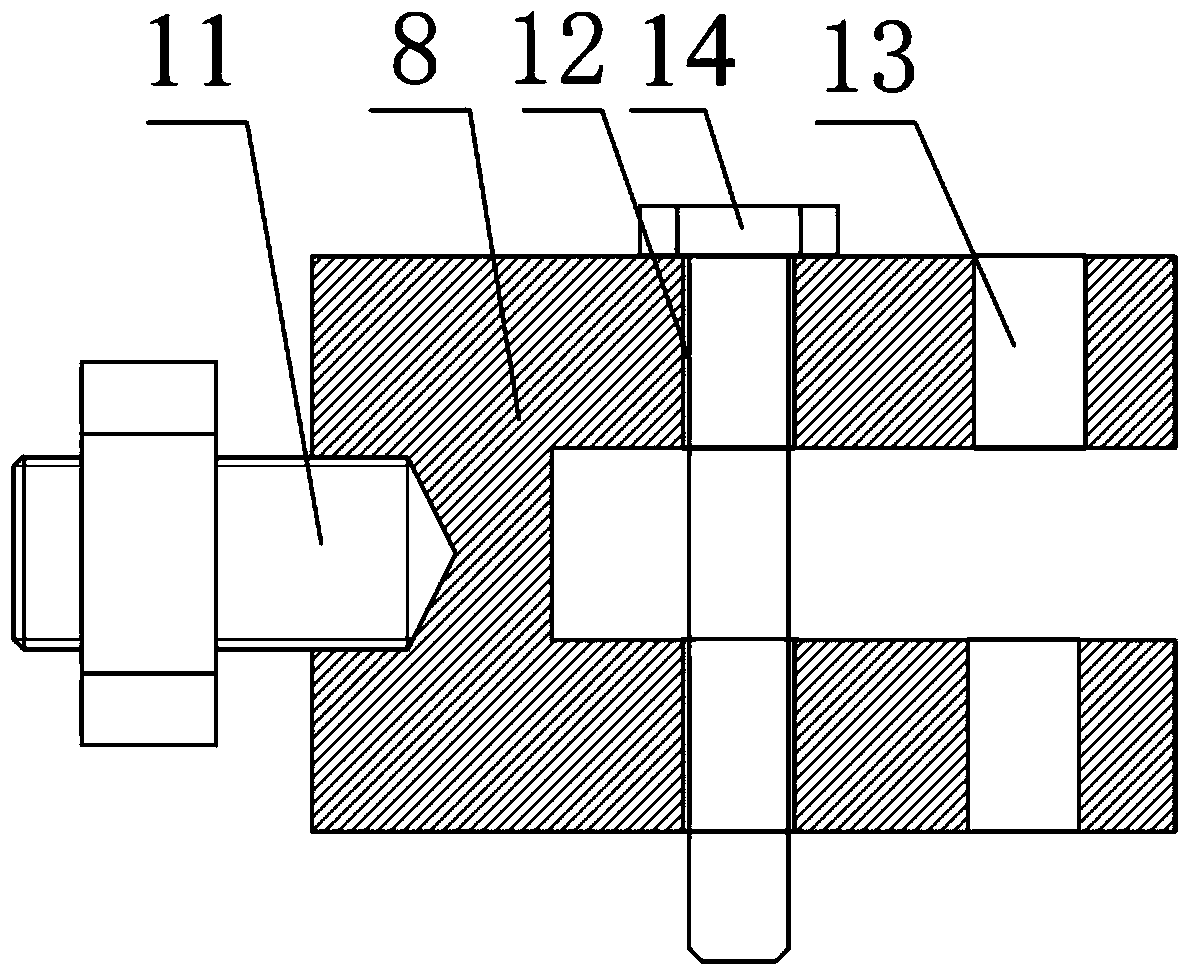

Calibration device for inclination angle sensor

InactiveCN101750099AGuaranteed placementAvoid Calibration ErrorsMeasurement devicesFixed frameEngineering

The invention discloses a calibration device for an inclination angle sensor, which is characterized in that a dividing head is arranged on an adjustable horizontal base; a three-jaw chuck fixedly connected with the lateral part of the dividing head is used for clamping a sensor fixed frame; an angular displacement platform capable of adjusting a horizontal inclination angle is mounted on the sensor fixed frame; a to-be-calibrated sensor is mounted on the angular displacement platform through a sensor clamp; the dividing head adopts a rotatable component with a horizontal rotating shaft; the end of the horizontal rotating shaft of the dividing shaft is fixedly connected with a rotating handle; the dividing head is used for measuring a rotating angle of the sensor fixed frame by means of an angle vernier coded disc and a dividing head angle coded disc arranged on the horizontal rotating shaft of the dividing head; and the rotating shaft of the sensor fixed frame and the rotating shaft of the dividing head are arranged at 90 degrees in a horizontal plane. The invention has the advantages of simple structure, high calibration accuracy and convenient use.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

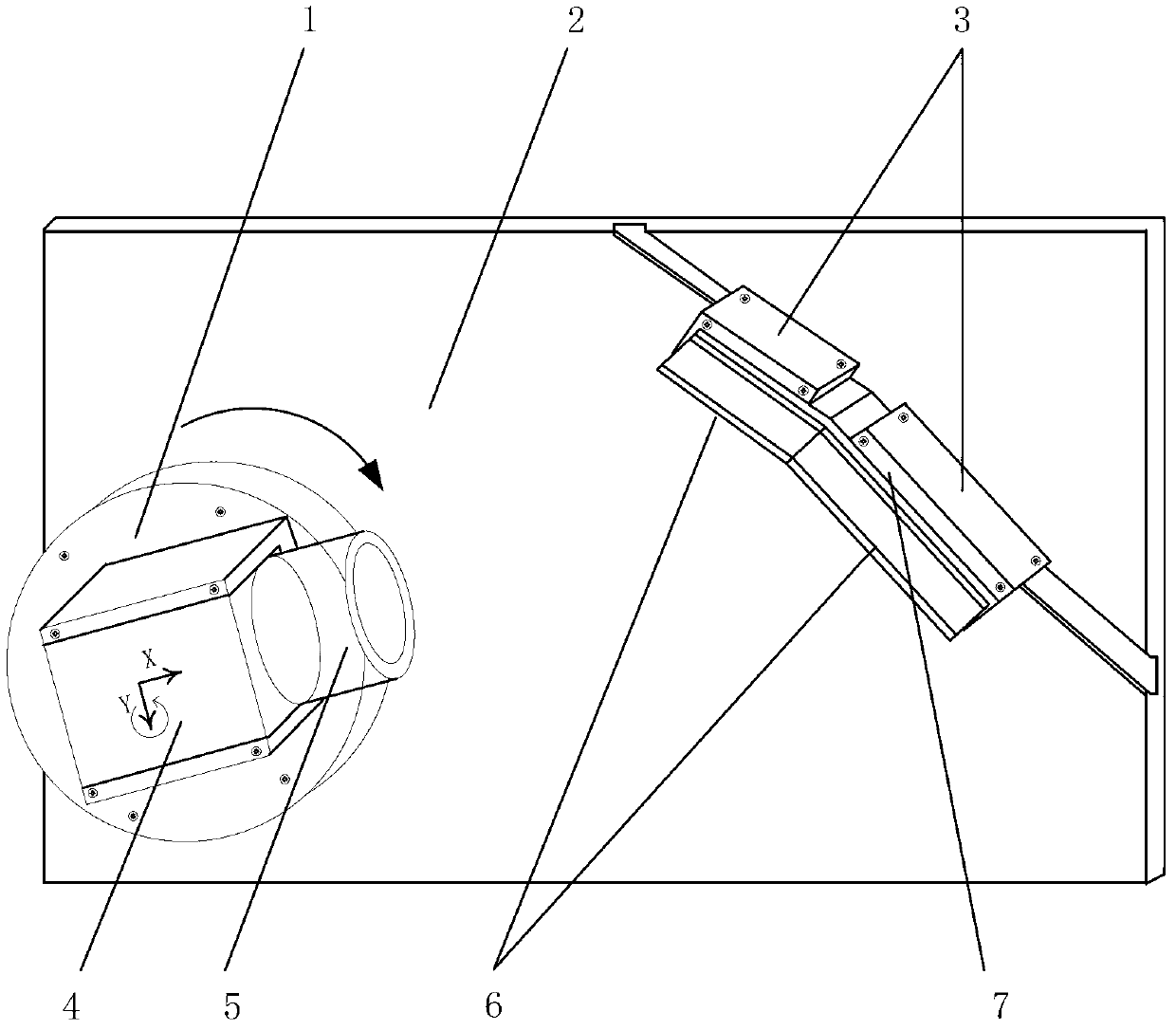

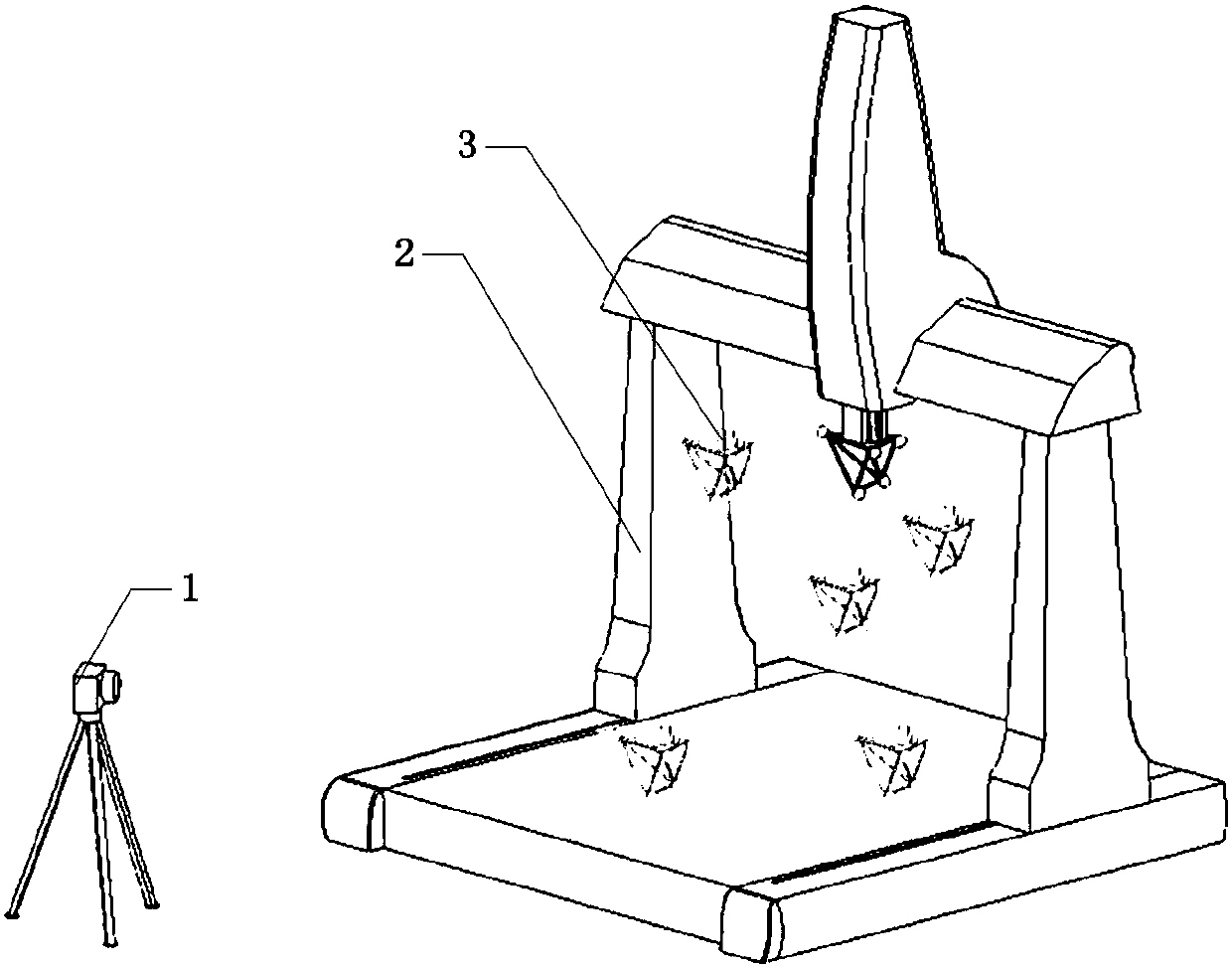

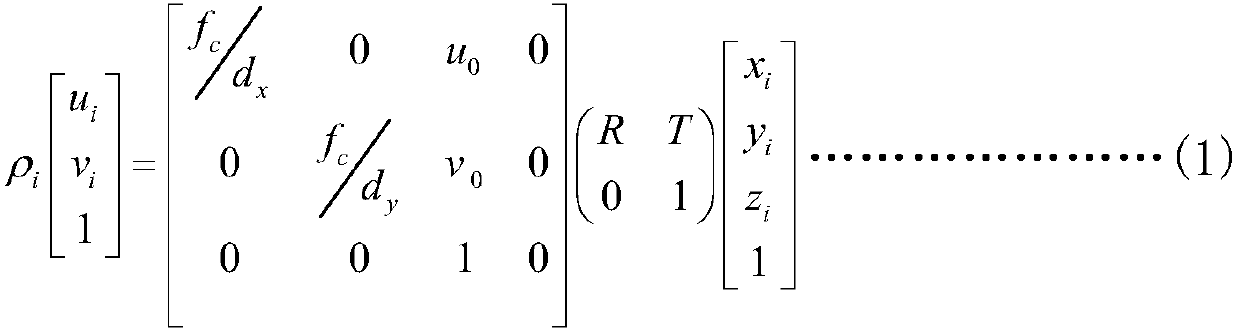

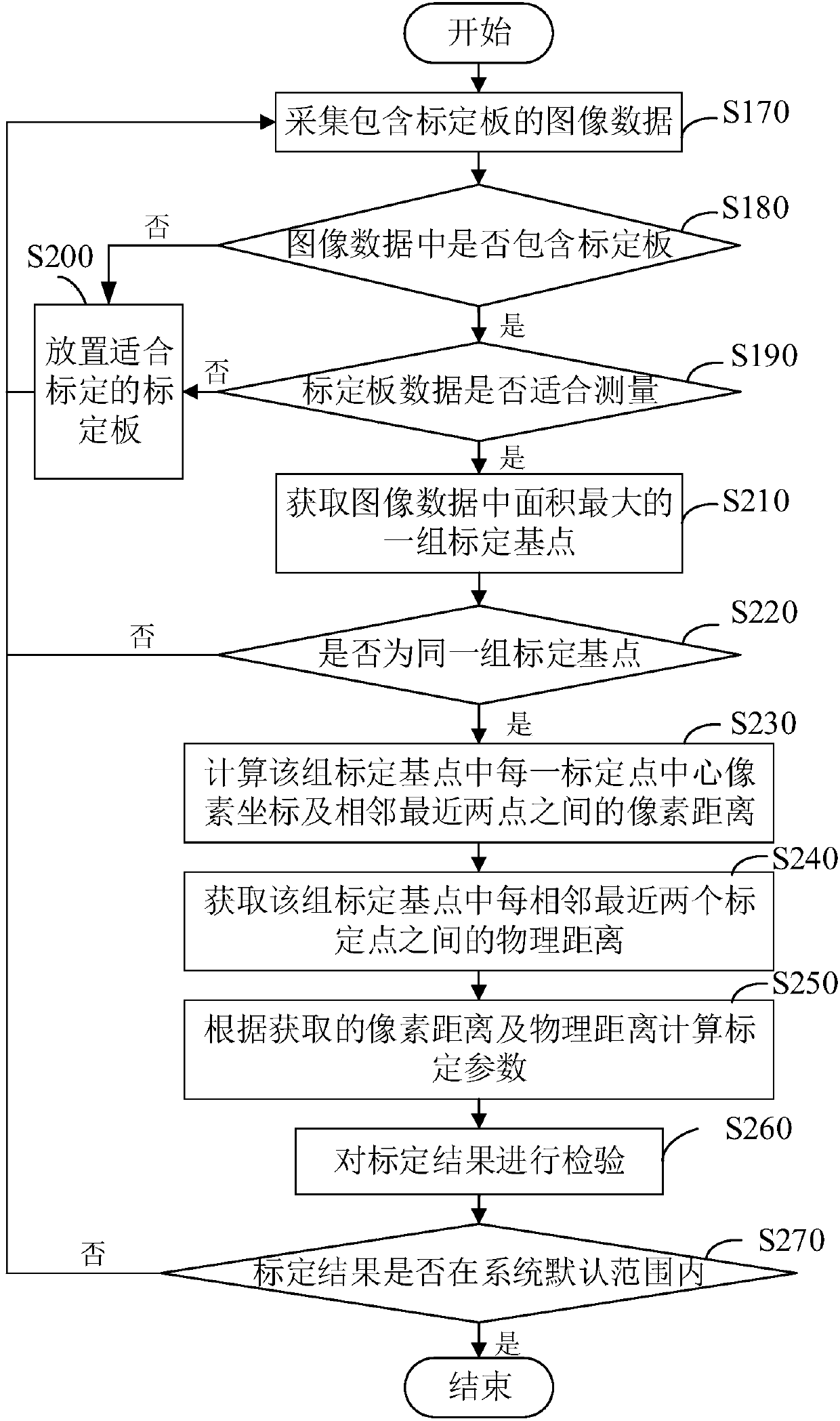

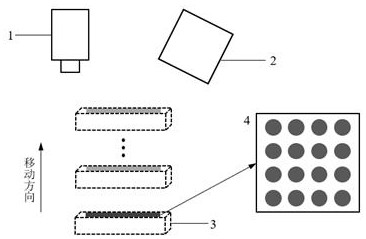

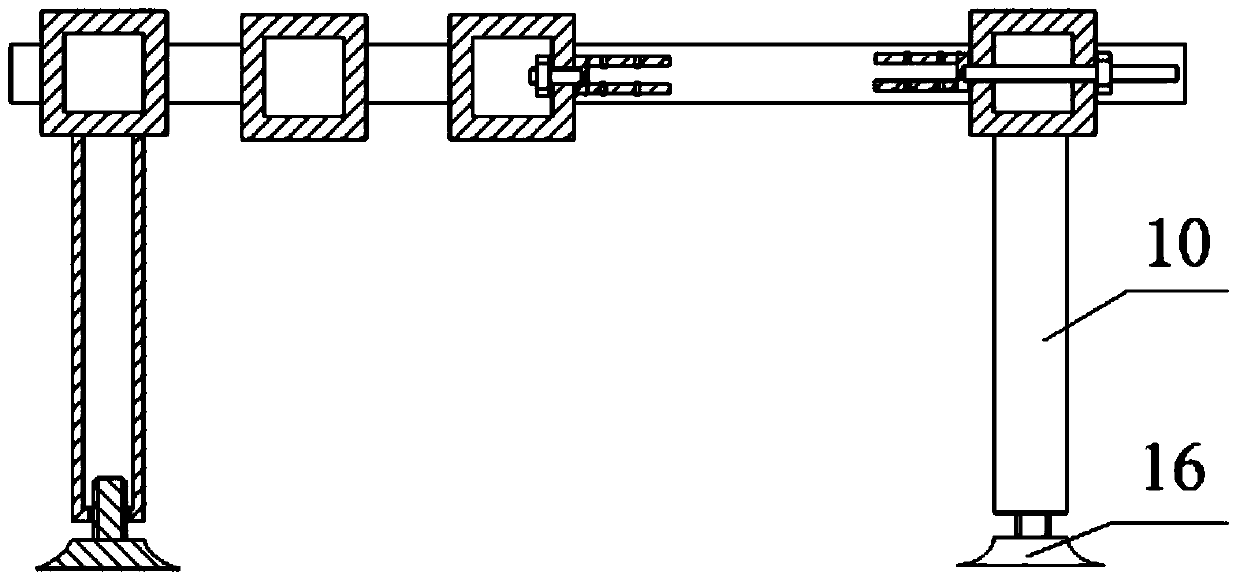

Movable-type calibration method for camera parameters of industrial photogrammetry system

InactiveCN107610178AMultiple Space Constraint InformationAvoid Calibration ErrorsImage analysisMovable typeThree dimensional motion

The invention discloses a movable-type calibration method for camera parameters of an industrial photogrammetry system, and the method comprises the steps: S1, selecting an optical target; S2, constructing a three-dimensional motion mechanism; S3, setting a to-be-calibrated industrial photogrammetry system; S4, recording the image coordinates, collected by the industrial photogrammetry system, ofthe optical center of the optical target; S5, obtaining the coordinate conversion relation between a pixel coordinate system of the industrial photogrammetry system and the world coordinate system through an industrial photogrammetry system imaging model; S6, calculating a calibration error.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

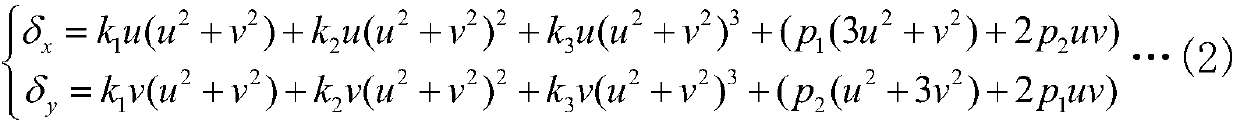

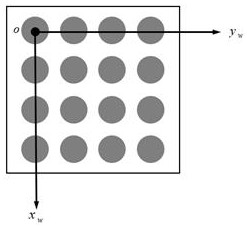

Vision-based robot automatic calibration method, equipment and storage medium

ActiveCN110640745AImprove calibration accuracyFast calibrationProgramme-controlled manipulatorComputer graphics (images)Radiology

The invention discloses a vision-based robot automatic calibration method, equipment and a storage medium. A MARK point is fixed at the tail end of a robot, and the attitude of the MARK point is observed with a camera. The calibration method includes the steps that (1) the robot moves by nine step lengths to obtain nine point locations which are in a 3*3 manner, position coordinates of the tail end of the robot in a robot coordinate system and pixel coordinates of the MARK point in the camera coordinate system are recorded in correspondence with all the point locations, the recorded position coordinates and pixel coordinates of the nine point locations are processed according to a nine-point calibration method, and a mapping matrix X3*3 between the robot coordinate system and the camera coordinate system is obtained; (2) according to the mapping matrix X3*3, a tool coordinate system T(Xt,Yt,theta) is calculated and established with the MARK point as the center; and (3) a conversion relationship between the pixel coordinates and the position coordinates of MARK point is calculated according to the tool coordinate system T and the mapping matrix X3*3, and nine-point calibration of the camera coordinate system to the robot coordinate system is achieved. The calibration method does not require manual teaching, simplifies the calibration process and effectively improves the calibration speed and the calibration accuracy.

Owner:SUZHOU UNIV

3D automobile wheel positioner multi-camera calibration system and method

ActiveCN104316335ASmall sizeReduce weightUsing optical meansVehicle wheel testingMulti cameraCalibration result

The invention provides a 3D automobile wheel positioner multi-camera calibration system and method. The 3D automobile wheel positioner multi-camera calibration system and method are mainly used for conducting production and maintenance field calibration on the 3D automobile wheel positioner multi-camera system. The information of the relative positions of two target boards is obtained through a calibration camera, two measurement cameras each obtain the position information of one target board, and finally the relative position relation of the second measurement camera relative to the first measurement camera is calculated. An extra target board is not needed in the calibration system, a calibration rod does not need to be used for rigid connection of the two target boards, calibration results are high in accuracy, the size and the weight of the calibration system are greatly reduced, maintainers can conveniently carry the system, the calibration steps are simple, operation is convenient, and relevant cost is reduced.

Owner:烟台开发区海德科技有限公司 +1

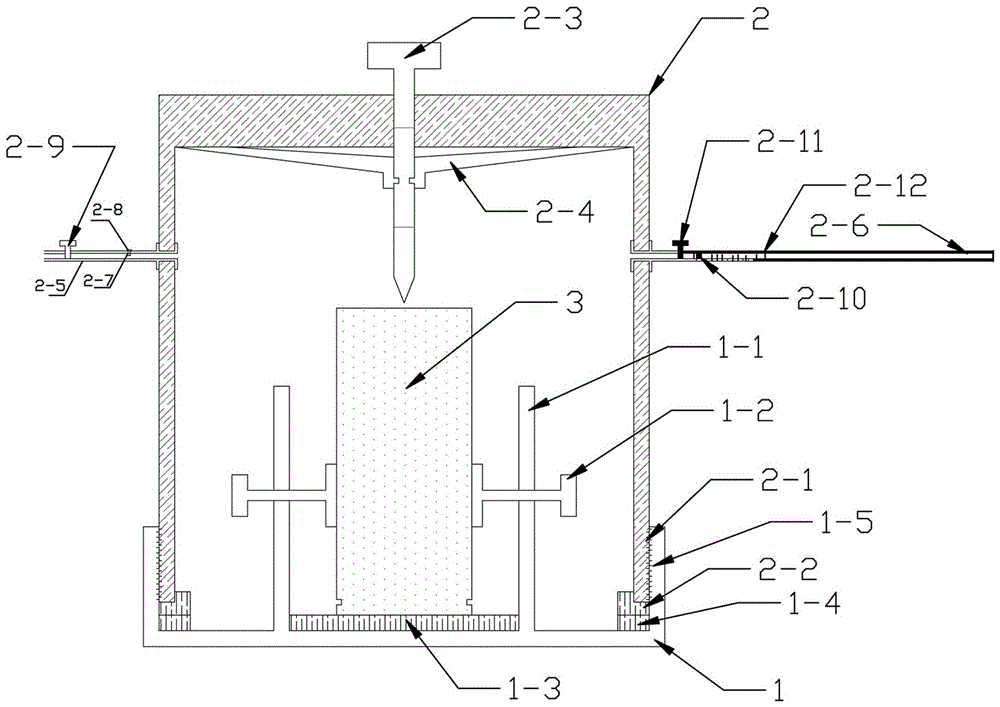

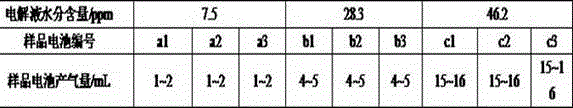

Device for detecting gas production rate of cylindrical lithium ion battery and application method thereof

ActiveCN106525190ASmall amount of deformationResistance to electrolyte corrosionVolume measurement apparatus/methodsProduction rateAcupuncture

The invention discloses a device for detecting the gas production rate of a cylindrical lithium ion battery and an application method thereof and aims at solving the technical problem that the gas production rate of the cylindrical lithium ion battery is efficiently and accurately detected. The device for detecting the gas production rate of the cylindrical lithium ion battery comprises a base and an upper cavity component, wherein the base and the upper cavity component form a closed cavity; the cylindrical lithium ion battery is fixed on the base; an acupuncture component is arranged at the top of the upper cavity component; the acupuncture component is connected with the inner wall of the upper cavity component by virtue of an upper cavity component sealing pad; an air exhaust PP pipe and a sealing oil liquid column PP pipe are arranged on the side wall of the upper cavity component; the air exhaust PP pipe and the sealing oil liquid column PP pipe are respectively provided with a valve; a pipe wall hole is also formed in the air exhaust PP pipe; a rubber plug is arranged in the pipe wall hole; and the sealing oil liquid column PP pipe is a transparent pipe provided with an oil liquid column and a blind end at the tail end. The device disclosed by the invention has the advantages that shell walls of the base and the upper cavity component are made from a stainless steel material respectively, small in deformation, resistant to electrolyte corrosion, reusable and long in service life.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

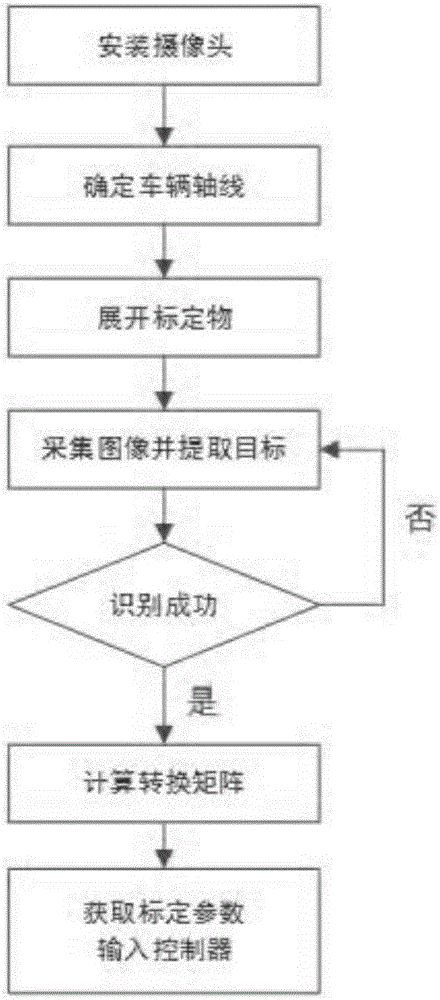

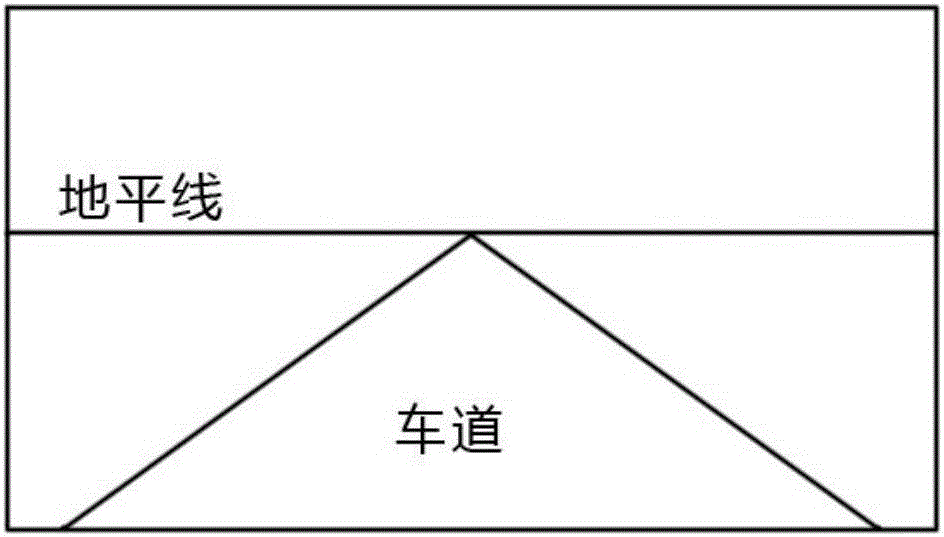

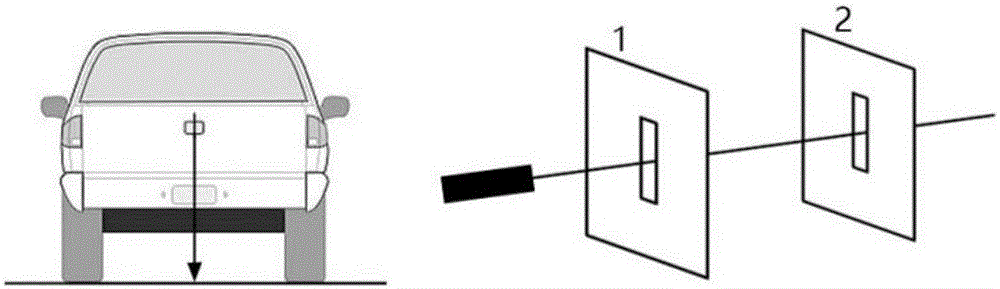

Mounting parameter calibration method for vehicular camera of driving assistant system

ActiveCN106651963AAvoid Calibration ErrorsAvoid errorsImage analysisCalibration resultInverse projection

The invention discloses a mounting parameter calibration method for a vehicular camera of a driving assistant system. The method comprises the steps of collecting calibration images and extracting HSV of the images; for a V channel, generating thresholds for segmented images through utilization of a maximum between-class variance method, carrying out binarization processing on the images, and screening and segmenting calibration object areas through the binarized images, thereby obtaining an initial selection area of each calibration object; extracting edge features of the calibration objects, thereby obtaining edge images, processing the edge images, and determining the pixel positions of the calibration objects in the images through combination of a geometric constraint relationship between the initial selection binarized image information of the calibration objects and the placement of the calibration objects; calculating a projection matrix and an inverse projection matrix of the projection matrix according to image coordinates and physical coordinates of the calibration objects; and writing a calibration result into a controller. According to the calibration method, the cost of required devices is relatively low, the calibration method is applicable to batch mounting of various vehicles and is compatible with different heights and photographing angles, and an error resulting from size mismatch of calibration plates is avoided.

Owner:清华大学苏州汽车研究院(吴江)

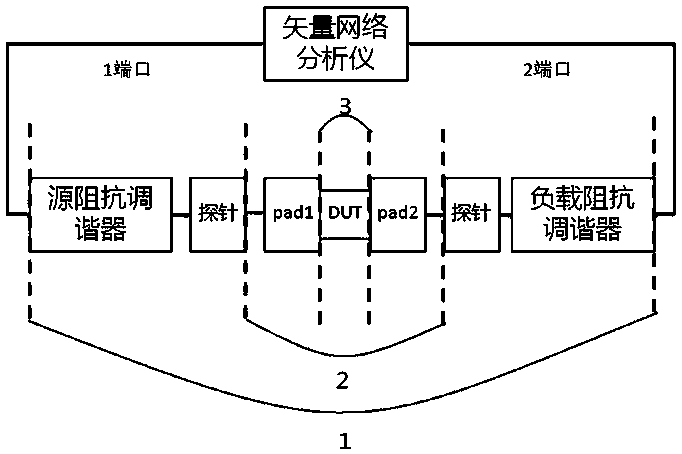

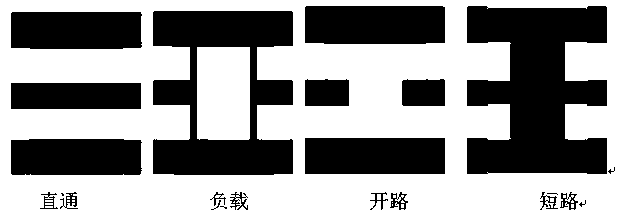

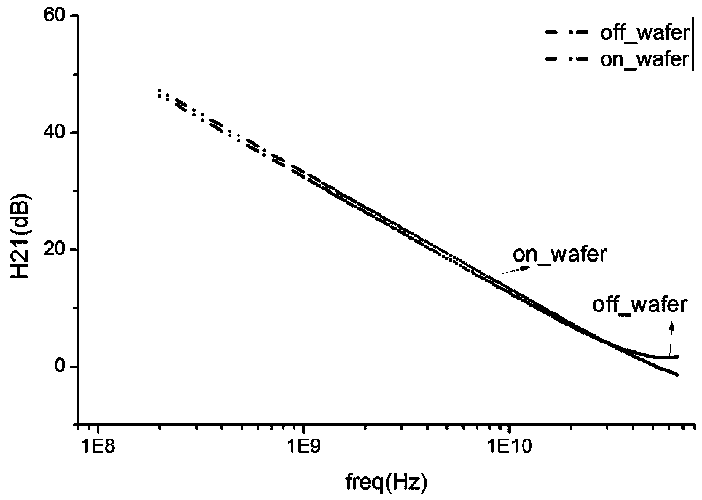

Calibration structure design for on-chip load traction test of devices and test method

InactiveCN109581259AImprove test accuracyImprove design yieldElectrical measurementsElectricityScattering parameters

The invention relates to a calibration structure for on-chip load traction test of devices. The calibration structure comprises an open circuit part, a short circuit part, a load part and a through part, wherein the load part, the open circuit part, the short circuit part and the through part are completely consistent with a to-be-tested device bonding pad in the aspect of structure. The inventionfurthermore discloses a test method suitable for the on-chip load traction test of devices, and the method comprises the steps of: 1) calibrating dual ports of a vector network analyzer; 2) calibrating an impedance tuner and measuring a 1-port scattering parameter (S parameter) of the load; 3) inputting the parameter; 4) calibrating the end surfaces of a device; and 5) carrying out power calibration and verification. The calibration structure and the test method have the advantages of: 1) ensuring the consistent electric characteristics of the calibration structure and to-be-tested chips, soas to avoid calibration errors caused by inconsistent materials and preparation processes of the calibration structure and to-be-tested pieces; and 2) effectively stripping the bonding pad and interconnection line parasitism, so as to improve the device test precision and improve the power amplifier design yield.

Owner:南京中电芯谷高频器件产业技术研究院有限公司

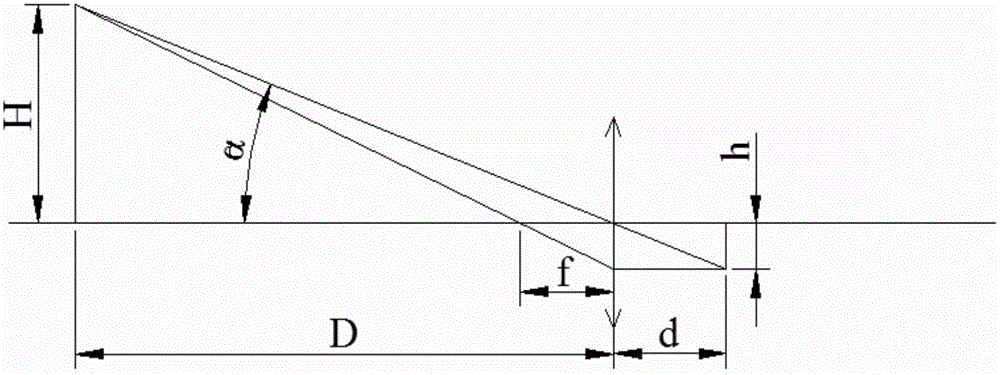

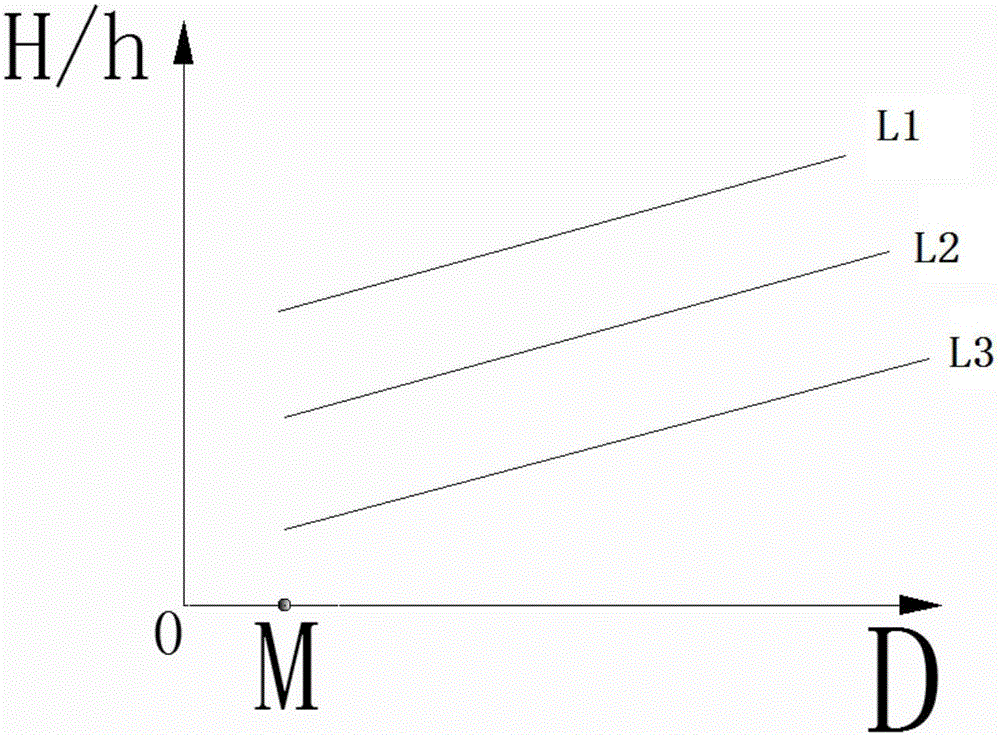

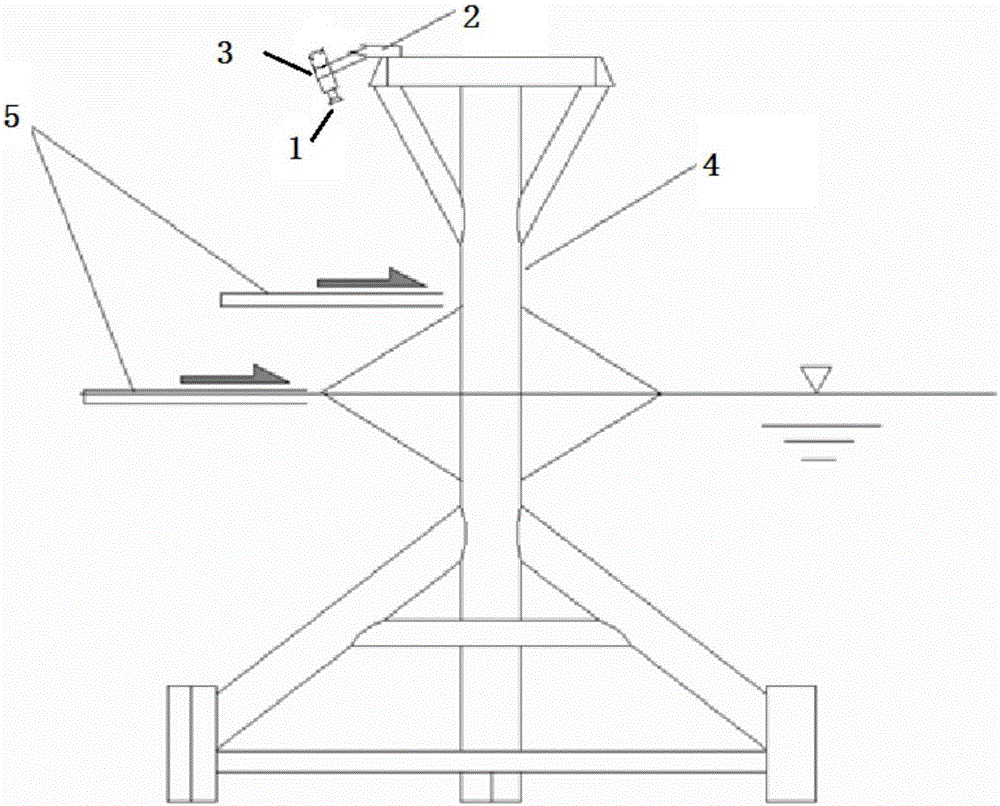

Field ice thickness and ice velocity automatic measuring method based on variable-focus image method

ActiveCN106017573AAvoid calibration difficulties and calibration errorsAvoid systematic errorsUsing optical meansHigh definitionMeasurement precision

The invention relates to a field ice thickness and ice velocity automatic measuring method based on a variable-focus image method. The field ice thickness and ice velocity automatic measuring method belongs to the technical field of ocean engineering. The field ice thickness and ice velocity automatic measuring method comprises the steps of: step 1, calibrating a function K in a laboratory; step 2, and carrying out actual measurement on ice thickness and ice velocity in the field, wherein the function K which is calibrated in the laboratory is automatically invoked according to focal length information f fed back by a variable-focus high-definition camera and distance information D fed back by a distance measuring instrument when processing images, and length or displacement distance H of an object can be calculated accurately with the combination of pixel size h of the displacement distance of a sea ice fracture surface or a feature point within a certain period of time. The field ice thickness and ice velocity automatic measuring method avoids system errors made in the actual measurement process, can be used for measuring the distance between the camera and the ice surface accurately, improves the measurement precision, is high in system adaptability, simple in structure and high in reliability, can adapt to harsh offshore working conditions of high humidity and high salinity, ensures the reliable operation of the system so as to obtain complete ice thickness and ice velocity data, and provides an important basis for the safety monitoring of an offshore platform.

Owner:DALIAN UNIV OF TECH

Device for calibrating tension and compression type residual stress

ActiveCN106153458AEasy and accurate calibrationThe stress-strain relationship is convenient and accurateMaterial strength using tensile/compressive forcesStress measurementEngineering

The invention discloses a tension-compression type residual stress calibration device, which belongs to the technical field of experimental stress measurement in material processing. The device includes a tension and compression loading mechanism, a clamping mechanism and a supporting mechanism. The tension-compression loading mechanism applies uniform tensile or compressive stress in the direction of the entire thickness of the calibration material; the clamping mechanism can adjust the clamping position according to the tension-compression type of the calibration material; the tension-compression loading mechanism and Clamping mechanism, and can adjust the height by itself. The present invention can be used as a supporting loading device for residual stress detection methods such as blind hole method, indentation strain method, etc., to accurately calibrate the stress-strain relationship of materials under tensile stress state and compressive stress state. It solves the problems of convenience and ease of use but uneven stress field during three-point bending loading, or the need for large-size samples and difficult loading when using a tensile testing machine for calibration.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

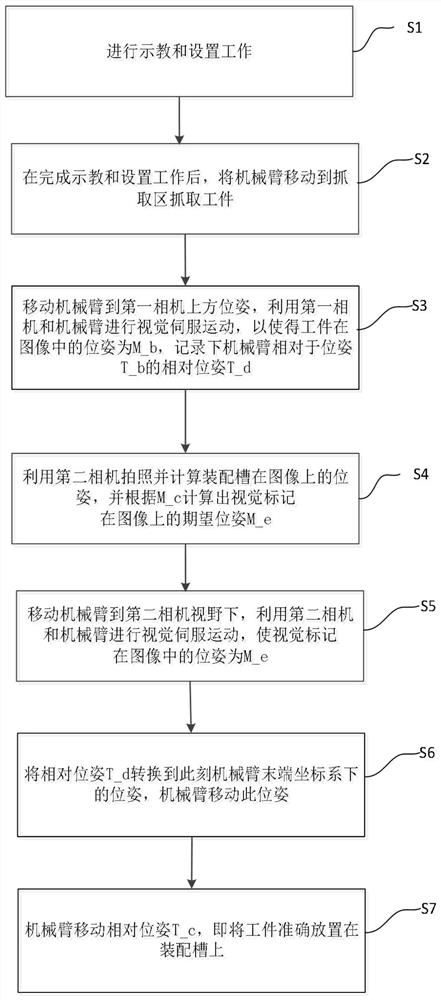

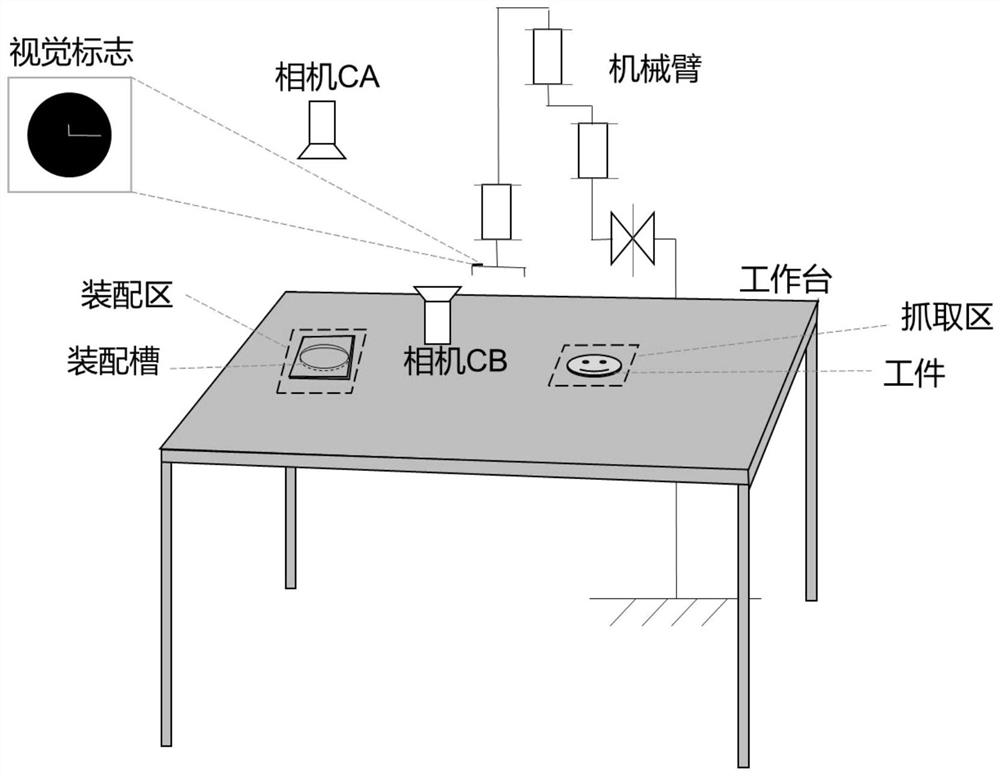

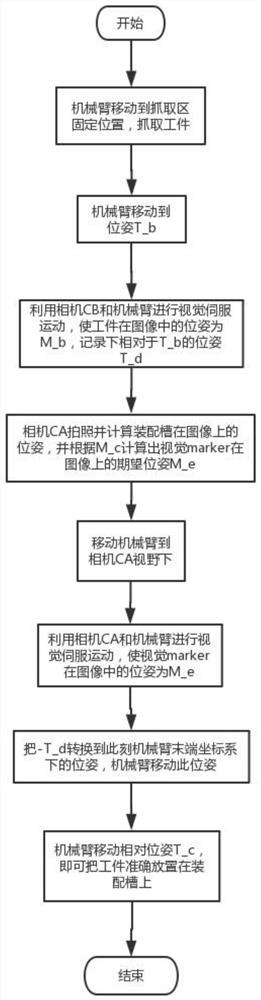

Robot high-precision assembling method based on visual servo

ActiveCN112894823AAvoid Calibration ErrorsAvoid errorsProgramme-controlled manipulatorVisual markingVisual servoing

The invention provides a robot high-precision assembling method based on visual servo. The robot high-precision assembling method comprises the steps that teaching and setting work is conducted; after the teaching and setting work is completed, a mechanical arm is moved to a grabbing area to grab a workpiece; the mechanical arm is moved to the position above a first camera, visual servo motion is conducted through the first camera and the mechanical arm, so that the position of the workpiece in the image is M_b, and the relative position T_d of the mechanical arm relative to the position T_b is recorded; a second camera is used for photographing and calculating the pose of an assembling groove on the image, and the expected pose M_e of a visual mark on the image is calculated according to the M_c; the mechanical arm is moved to the field of view of the second camera, visual servo motion is conducted through the second camera and the mechanical arm, and the pose of the visual mark in the image is made to be M_e; the relative pose T_d is converted to the pose under the coordinate system at the tail end of the mechanical arm at the moment, and the mechanical arm moves the pose; and the mechanical arm moves the relative pose T_c, namely the workpiece is accurately placed on the assembling groove.

Owner:ROKAE SHANDONG INTELLIGENT TECH CO LTD

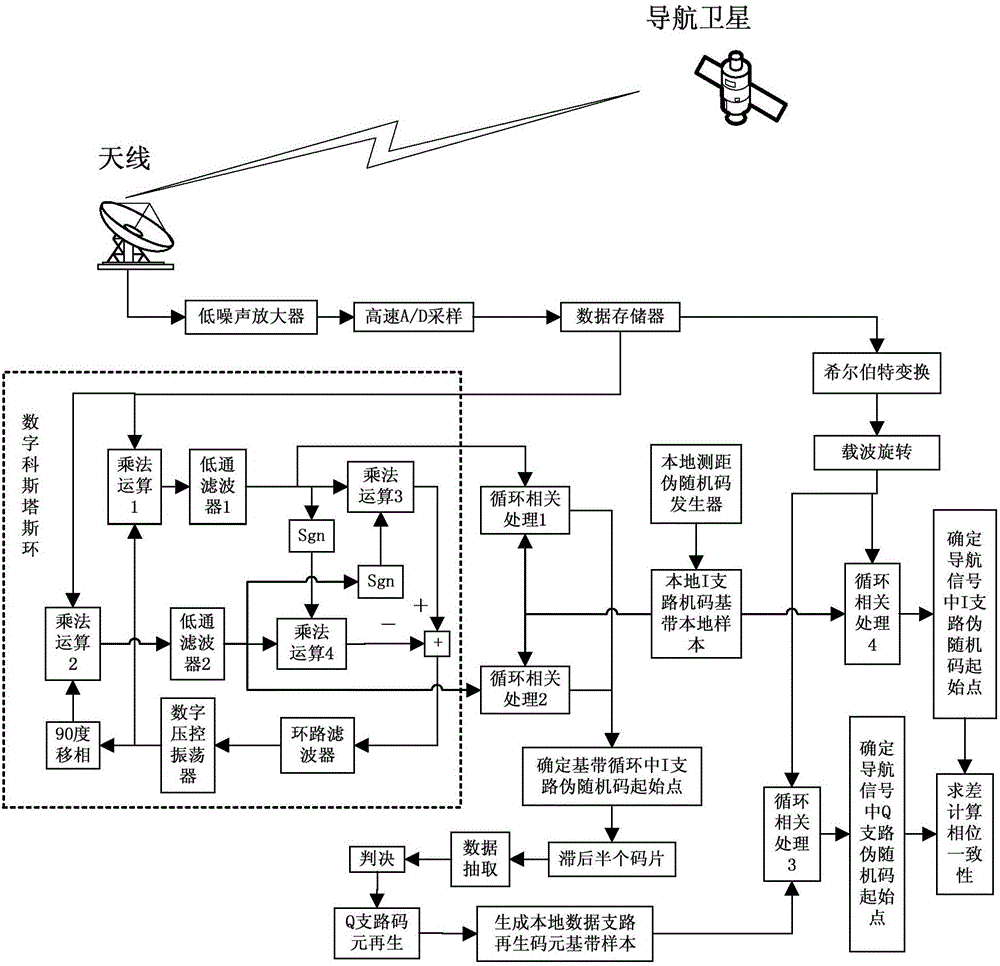

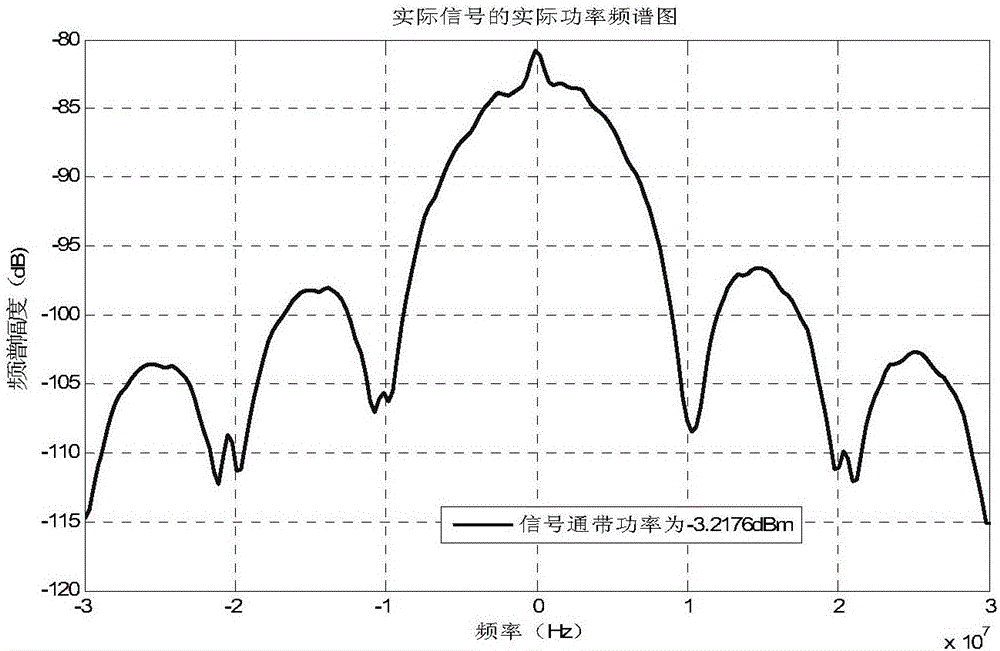

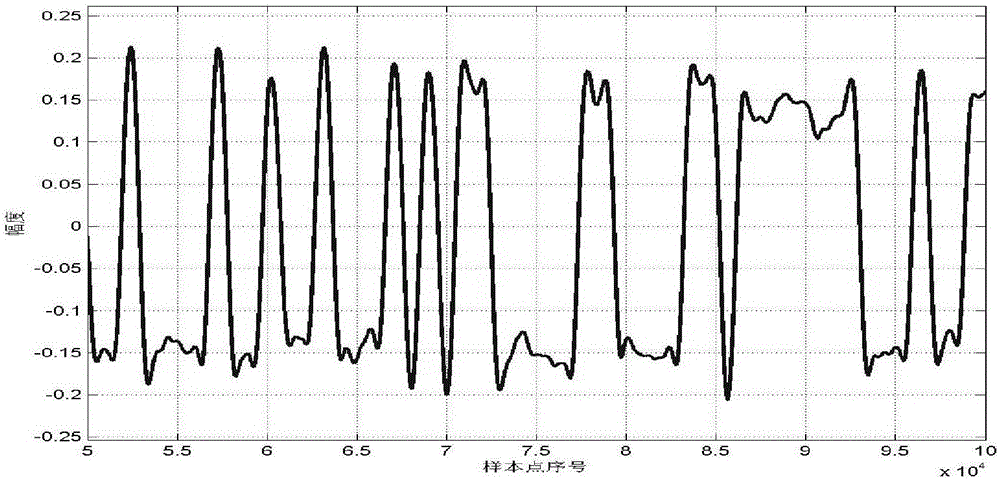

On-orbit navigation signal IQ phase consistency calibrating method

ActiveCN106226793AAvoid Calibration ErrorsPrecise determination of phase delay relationshipSatellite radio beaconingQuadrature demodulationCoded element

The invention discloses an on-orbit navigation signal IQ phase consistency calibrating method, and belongs to the field of satellite navigation. The method includes the steps of conducting high-speed sampling for navigation radiofrequency signals, conducting quadrature demodulation for the intercepted navigation signal sampling data to obtain two roadbed band data, determining the pseudo-random code start point of a navigation signal I branch through circular correlation processing, extracting the Q-path baseband signals according to the pseudo-random code sheet interval with the half code sheet delayed than the start point, regenerating code elements of the navigation signal Q branch, conducting circular correlation respectively for the navigation signal data by using the local I branch pseudo-random code and regenerated Q branch code elements, respectively determining the pseudo-random code start points of the I branch and the Q branch in the navigation signals, and calculating the phase consistency of a navigation signaling channel in combination with sampling rate. The method is applied in a digital domain, the calibrate errors caused by self zero value error of reception equipment in conventional test equipment can be avoided, and the calibrating precision is high.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Multi-scale calibration plate

Owner:苏州极拓智能科技有限公司

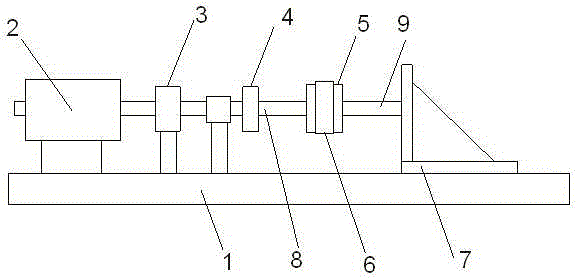

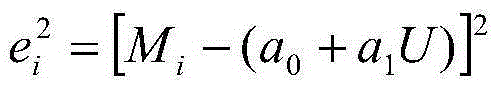

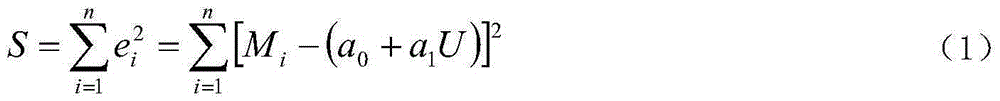

Transmission shaft torque calibration method

InactiveCN105352643AMeasure the twist angleMeasured torsional stiffnessMachine gearing/transmission testingApparatus for force/torque/work measurementDrive shaftCalibration coefficient

The invention discloses a transmission shaft torque calibration method, comprising steps of installing a transmission shaft to be measured on a test stand, installing a strain gauge wireless measurement system on the transmission shaft, applying a torque on the transmission shaft, outputting a corresponding voltage value through a strain gauge wireless measurement system, establishing a transmission shaft torque calibration model and obtaining a calibration coefficient through calculation. The transmission shaft torque calibration method can conveniently, fast, accurately and reliably calibrate the torque of the transmission shaft.

Owner:CHONGQING UNIV OF TECH

A method for calculating and calibrating that zero angle of a rotor position sensor of a permanent magnet synchronous motor

ActiveCN109004875AOvercoming the Effects of Zero Angle CalibrationHigh precisionElectronic commutation motor controlVector control systemsReverse currentPermanent magnet synchronous motor

A method for calculating zero angle of rotor position sensor of permanent magnet synchronous motor disclosed in the invention includes defining P physical zero angles, forward rotation direction and reverse rotation direction of rotor of permanent magnet synchronous motor in one revolution; Calculating a given current vector of forward rotation and reverse rotation of a rotor at each physical zeroangle position of the motor; The zero angle of each physical zero angle position forward rotor position sensor and the zero angle of the reverse rotor position sensor are obtained by loading the forward and reverse current vectors of the motor. The zero angle of each physical zero angle position forward rotor position sensor and the zero angle of the reverse rotor position sensor are obtained. The forward and reverse loads of the motor are measured, and the zero angle errors of the forward rotor position sensor and the reverse rotor position sensor of each physical zero angle position are eliminated by weighted calculation, so that the zero angle of each physical zero angle rotor position sensor is obtained. The invention also discloses a zero angle calibration method of a rotor positionsensor of a permanent magnet synchronous motor. The invention can avoid the error caused by the load to obtain more accurate zero angle of the rotor position sensor and more accurately calibrate the zero angle of the rotor position sensor.

Owner:SAIC MOTOR +1

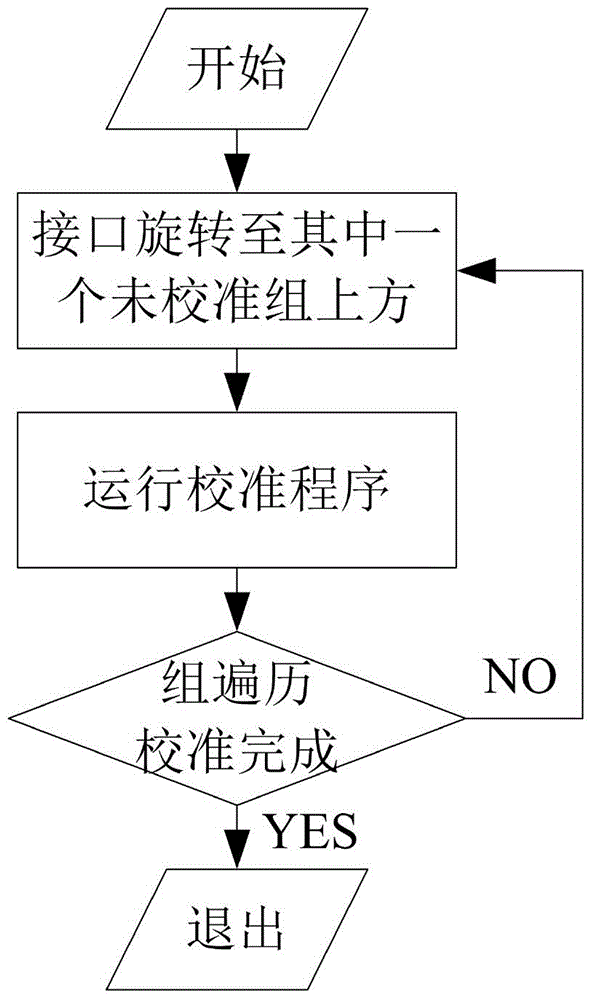

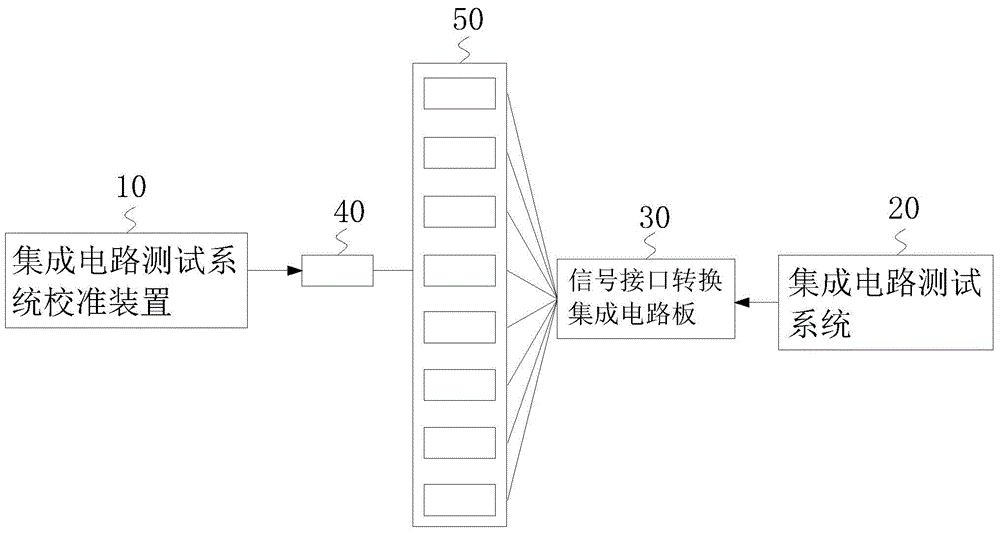

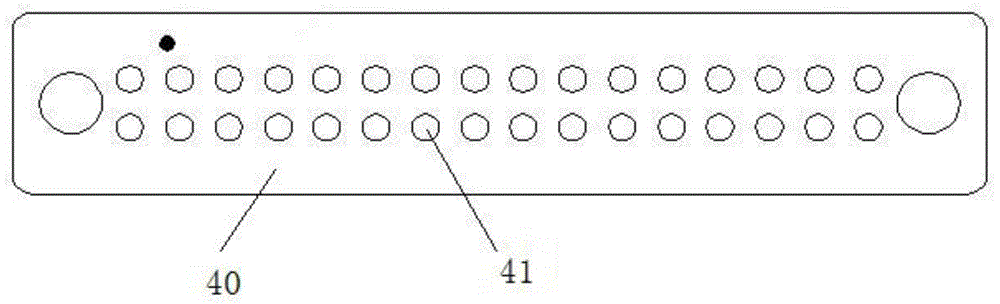

Multi-channel symmetric calibration method of integrated circuit testing system and interface switching device of integrated circuit testing system

ActiveCN104535950AEnsure consistencyAvoid Calibration ErrorsElectrical measurementsIntegrated circuitEngineering

The invention provides a multi-channel symmetric calibration method of an integrated circuit testing system and an interface switching device of the integrated circuit testing system. With the number of calibration channel interfaces of the integrated circuit testing system as the benchmarke, the channel interfaces of the integrated circuit testing system are divided into groups in sequence, and the number of types of each group of testing channel interfaces is made to be exactly identical with the number of the channel interfaces of each type; meanwhile, type arrangements of each group of the testing channel interfaces are exactly the same; the calibration channel interfaces sequentially calibrate each group of the testing channel interfaces until all the testing channel interfaces are calibrated. The channel interfaces of the integrated circuit testing system are divided into the groups and are calibrated in group, therefore, thousands of the channel interfaces of the integrated circuit testing system can be accurately switched, massive switching matrixes and module switching matrixes are shortened, and the anti-interference capacity is improved.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

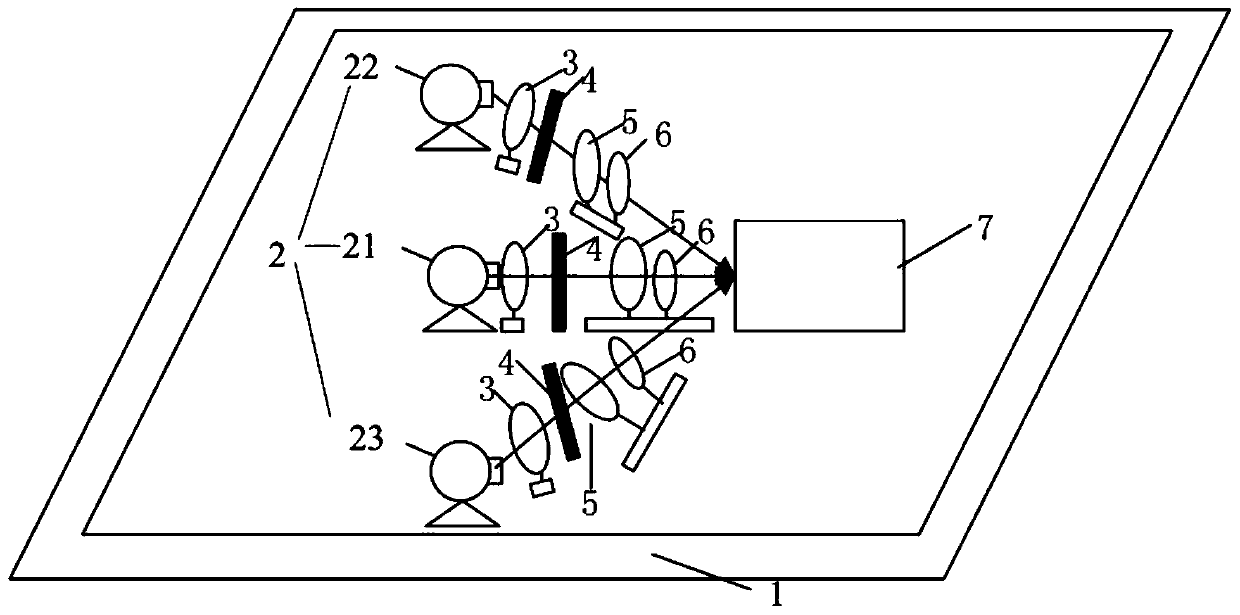

Low-value calibration device and calibration method for ultraviolet irradiance meter

The invention relates to a low-value calibration device and method for an ultraviolet irradiance meter. The device comprises an optical platform, three sets of calibration basic units located on the optical platform and a standard ultraviolet irradiance meter. Each set of calibration basic unit comprises an ultraviolet light source, a precision diaphragm, a blind plate, an optical filter group andan attenuation sheet group which are sequentially arranged on the same straight line. The ultraviolet light sources of the three sets of calibration basic units are respectively a first ultraviolet light source positioned at the middle position, a second ultraviolet light source positioned at the rear part and a third ultraviolet light source positioned at the front part; light emitted by the three incoherent ultraviolet light sources passes through the precision diaphragm, the optical filter group and the attenuation sheet group and then is converged at the center of the receiver of the standard ultraviolet irradiance meter, the calibrated ultraviolet irradiance meter is placed behind the attenuation sheet group at the middle position, and the center of the calibrated ultraviolet irradiance meter and the center of the attenuation sheet group are located on the same horizontal line. The device is few in calibration equipment, free of light rails and other equipment, easy to operate, low in cost, small in size and capable of being carried for on-site metering.

Owner:CHINA ELECTRONICS STANDARDIZATION INST

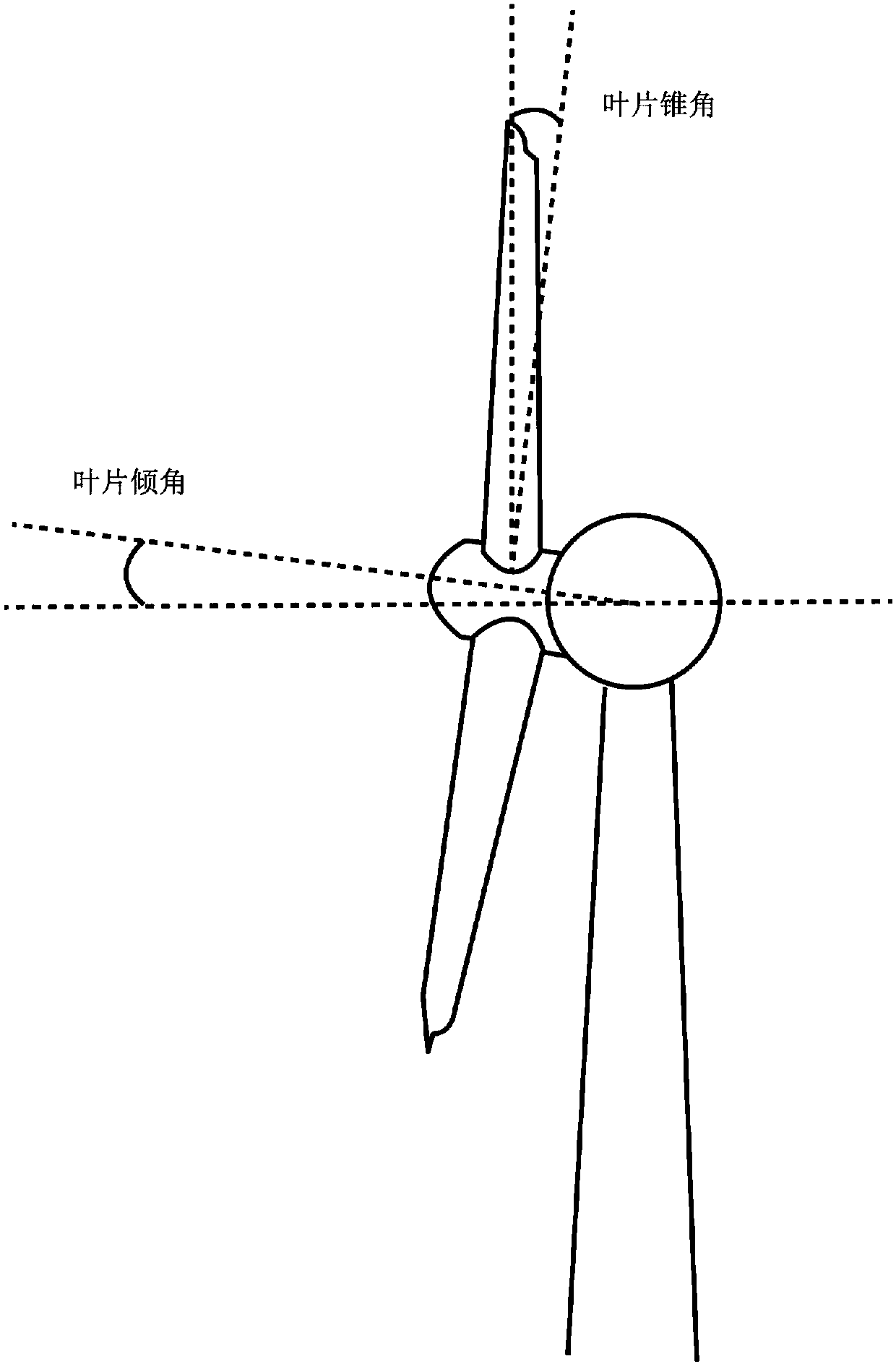

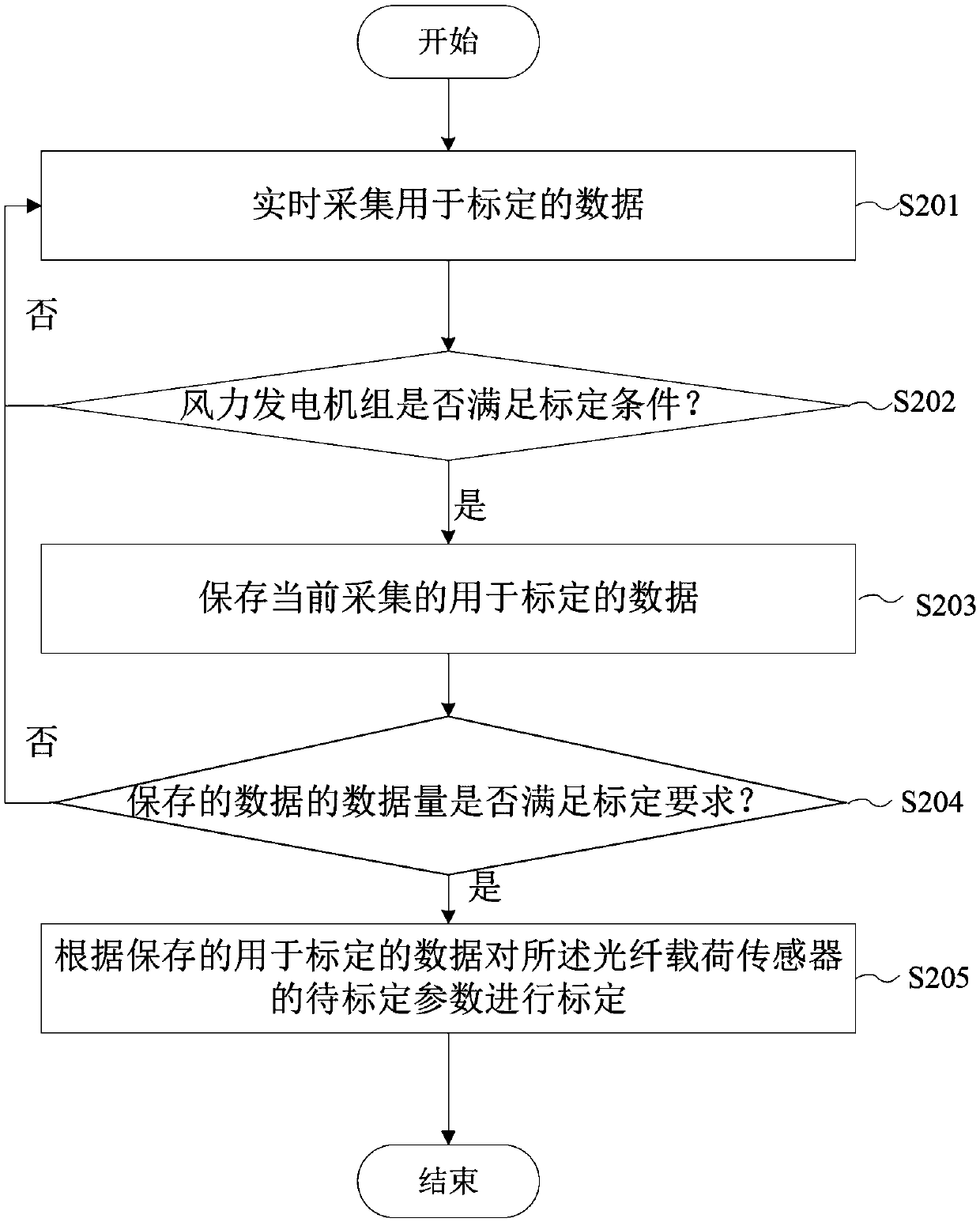

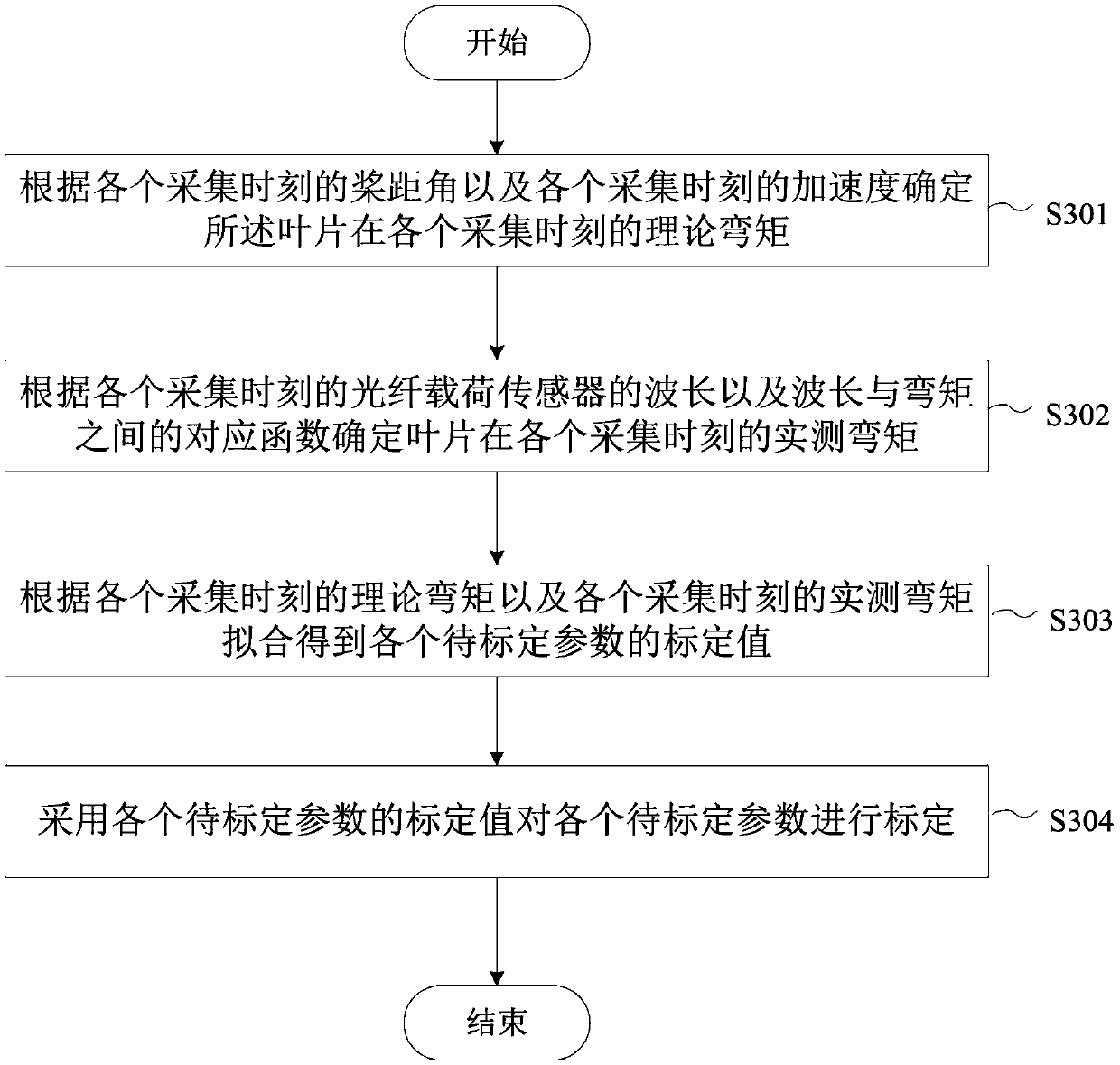

Calibration method and device for optical fiber load sensor of wind generating set

ActiveCN110761957ATimely updateAvoid Calibration ErrorsMachines/enginesWind motor monitoringAtmospheric sciencesElectrical and Electronics engineering

The invention provides a calibration method and device for an optical fiber load sensor of a wind generating set. The calibration method includes the steps that data for calibration is collected in real time, wherein the data for calibration includes a pitch angle of a blade of the wind generating set, the acceleration measured by an acceleration sensor installed in an impeller of the wind generating set and the wavelength of the optical fiber load sensor installed at the root of the blade; when the wind generating set meets calibration conditions, the currently collected data for calibrationis saved; and when the data volume of the saved data for calibration meets calibration requirements, parameters to be calibrated of the optical fiber load sensor are calibrated according to the saveddata for calibration. According to the calibration method and device, the data for calibration is collected in real time, once the conditions are met, calibration can be performed based on the collected qualified data, the calibration relationship can be updated in time, the accuracy is high, and a large amount of manpower and material resources can be saved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

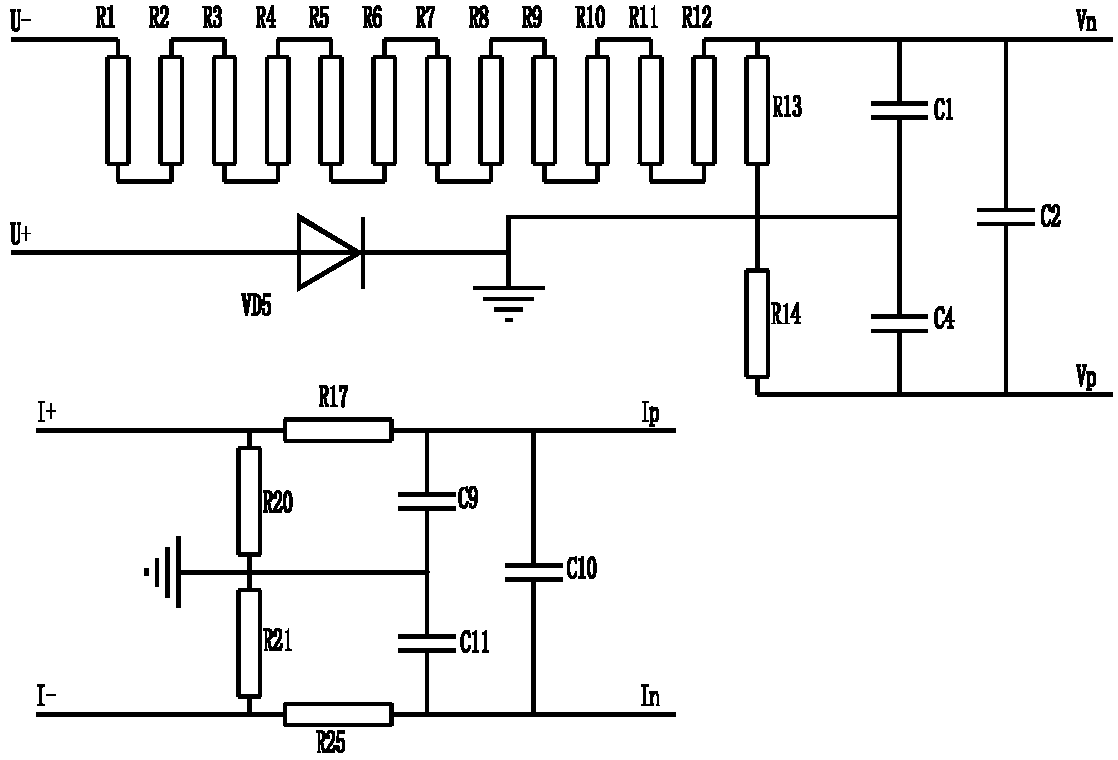

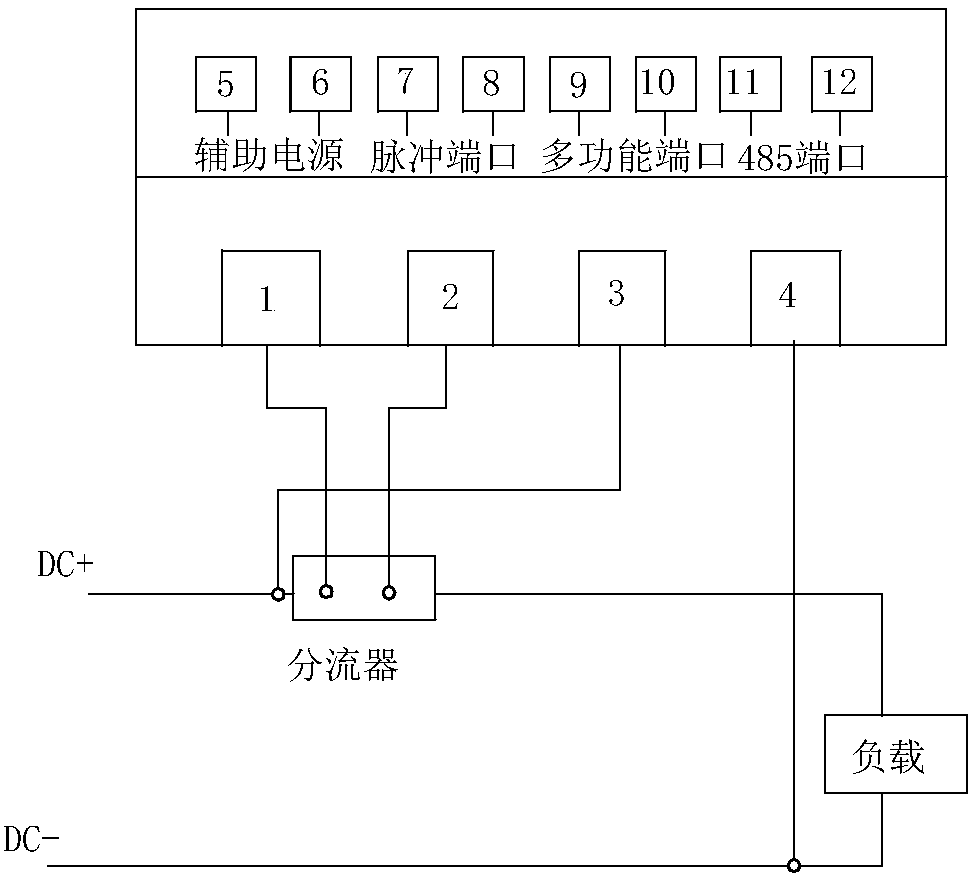

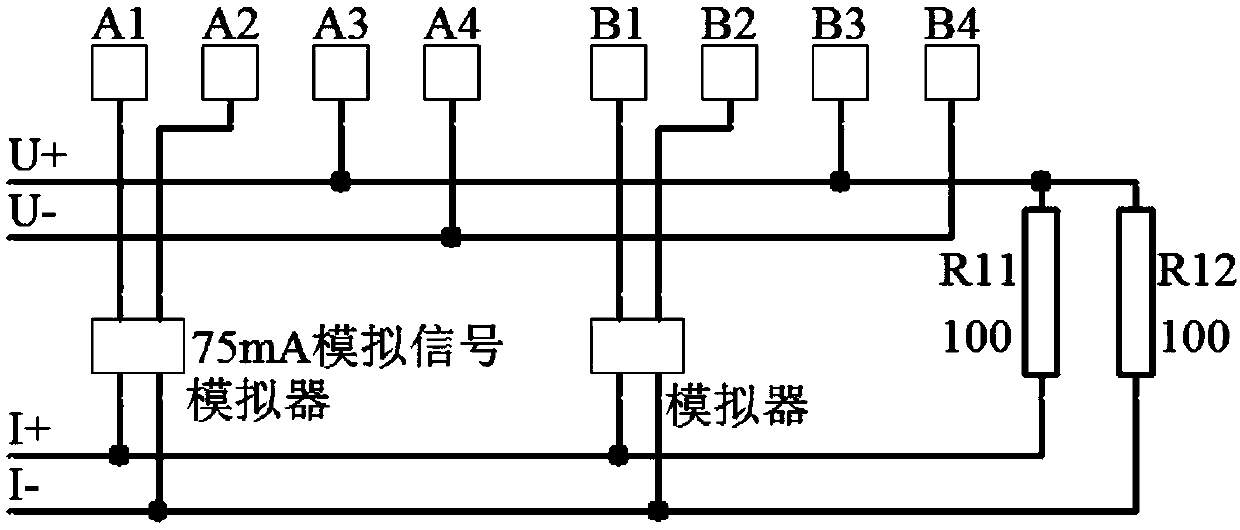

Direct-current energy meter

PendingCN107727899AImprove detection accuracyImprove stabilityTime integral measurementLiquid-crystal displayDc current

The invention relates to a direct-current energy meter. The direct-current energy meter comprises a direct-current sampling module (1) for collecting a current signal when the electric energy meter works; a direct-current voltage sampling module (2) for acquiring a voltage signal of the energy meter; a metering module (4) for receiving the acquired current signal and the voltage signal and analyzing and converting the current signal and the voltage signal; a control module (5) which is connected with the metering module (4), and receives information transmitted by the metering module (4) and performs bidirectional data communication; and a liquid crystal display module (9) for displaying power consumption data according to the information transmitted by the control module (5). The direct-current energy meter further comprises a voltage and current isolation module (3) for isolating the sampling voltage signals and the current signals and reducing interference between the sampling voltage signals and the current signals. Compared with the prior art, the direct-current energy meter is advantageous in that an isolation chip is arranged between a voltage sampling module and a current sampling module, so that the isolation of the two can be effectively realized, and the interference between the current signal and the voltage signal is effectively reduced. The metering accuracy of the energy meter is improved. When the voltage is reversely connected, the energy meter is intact, and the safety and the universality are ensured.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

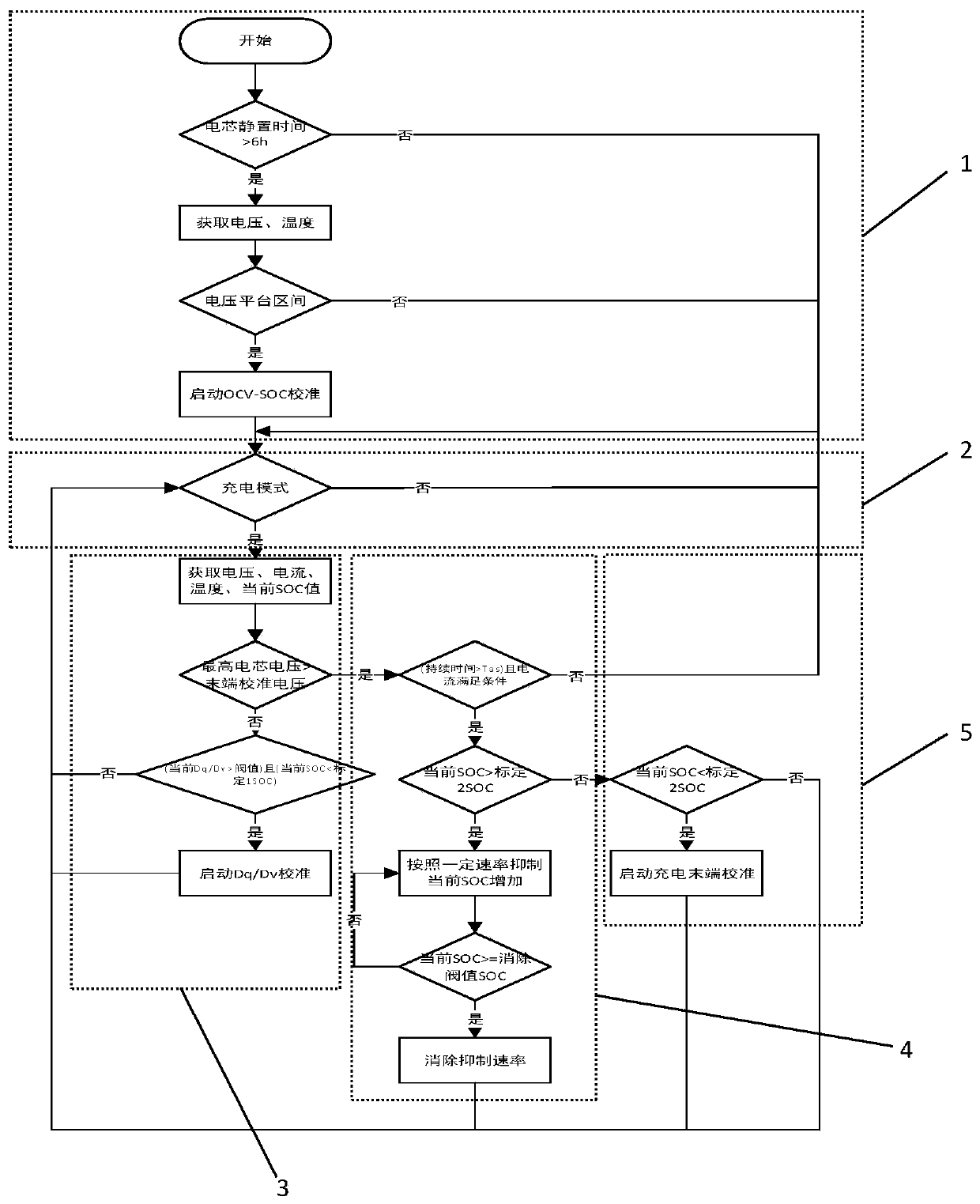

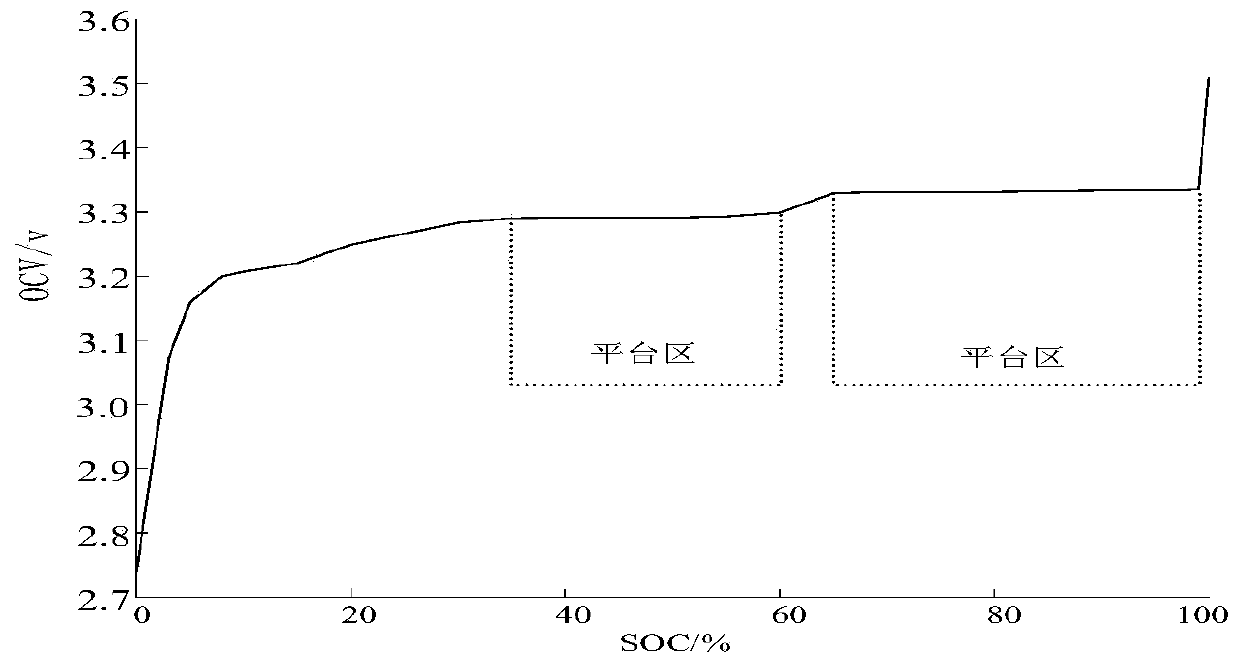

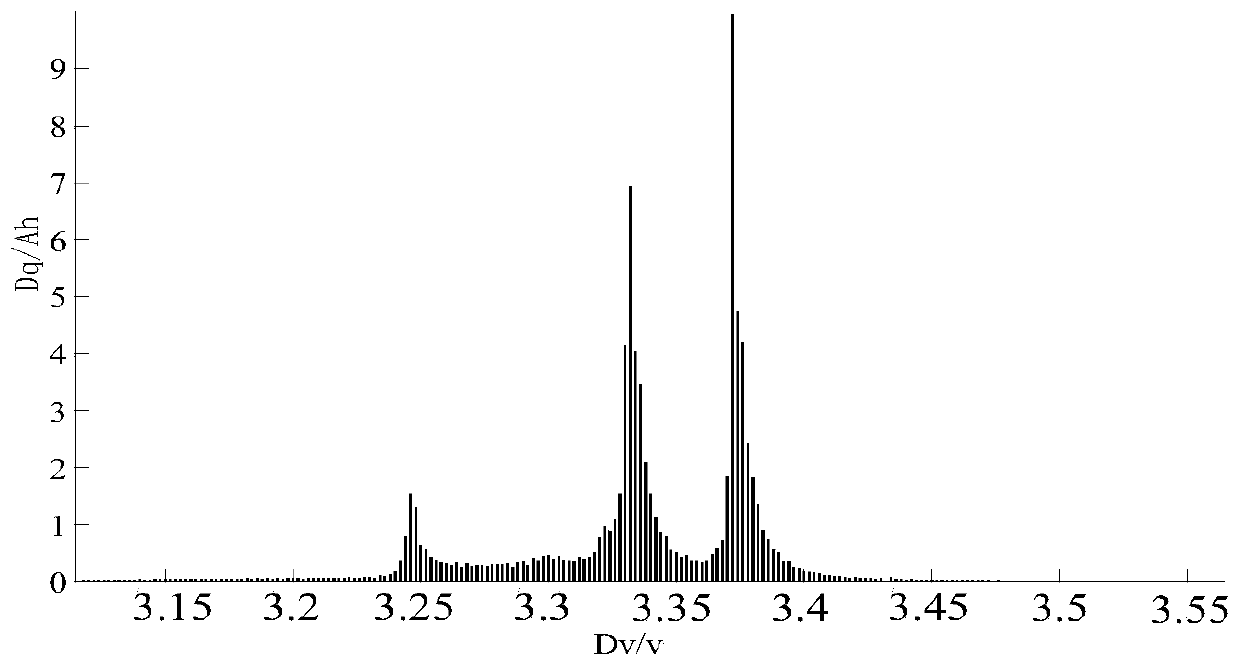

Battery SOC calibration method and device, and storage medium

ActiveCN111579998AIncrease chance of calibrationImprove Calibration AccuracyElectrical testingComputational physicsTerminal voltage

The invention provides a battery SOC calibration method. The method comprises the following steps of S1, powering on a system, reading the storage time and a storage SOC value in a readable memory, judging whether the standing time meets a threshold value or not, judging whether a platform area exists or not if the standing time meets the threshold value, starting OCV-SOC table look-up calibrationif the standing time meets the threshold value, and then carrying out the step S2, otherwise, directly carrying out the step S2; S2, judging whether a charging mode is adopted or not, if yes, readingthe current SOC value, the charging current, the charged time and the charging highest battery cell voltage, executing the step S3, otherwise, executing the step S2; S3, judging and calibrating a Dq / Dv relationship; S4, carrying out static voltage slope calibration; and S5, performing charging terminal voltage calibration. The SOC calibration method is advantaged in that SOC calibration is carried out in three modes of Dq / Dv relation, charging terminal voltage and static voltage slope judgment in the charging process, calibration errors caused by the fact that the battery cell exists in a platform area are avoided, and therefore the SOC calibration method is suitable for SOC calibration of different types of battery cells.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

Digital grating projection measurement system calibration method for expanding calibration space

The invention provides a digital grating projection measurement system calibration method for expanding a calibration space. The method comprises the following steps: S10, expanding the calibration space; and S20, obtaining a relation model between world coordinates and camera pixel coordinates and phases. According to the invention, the calibration space is expanded, the measurement space outsidethe calibration point is brought into the calibration range, and the relation model between the world coordinate and the camera pixel coordinate and phase is established in the space outside the calibration point, so that the calibration error is avoided.

Owner:三代光学科技(天津)有限公司

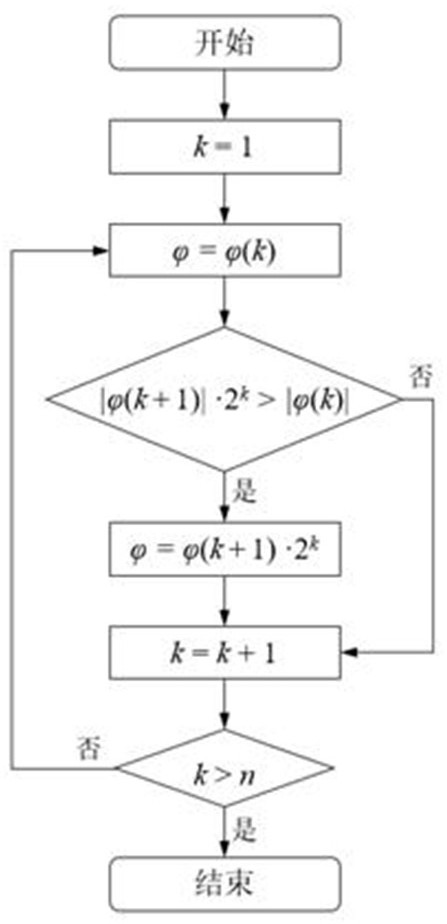

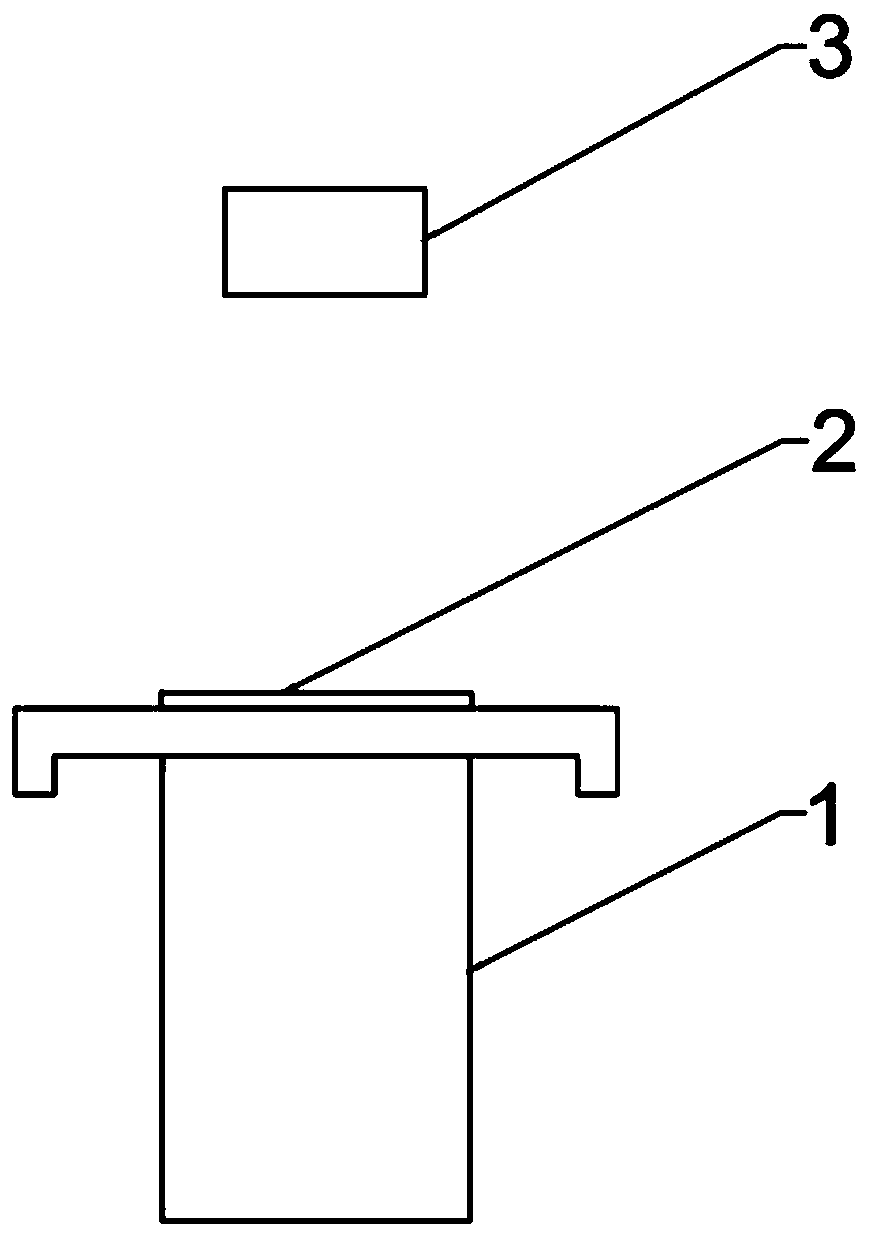

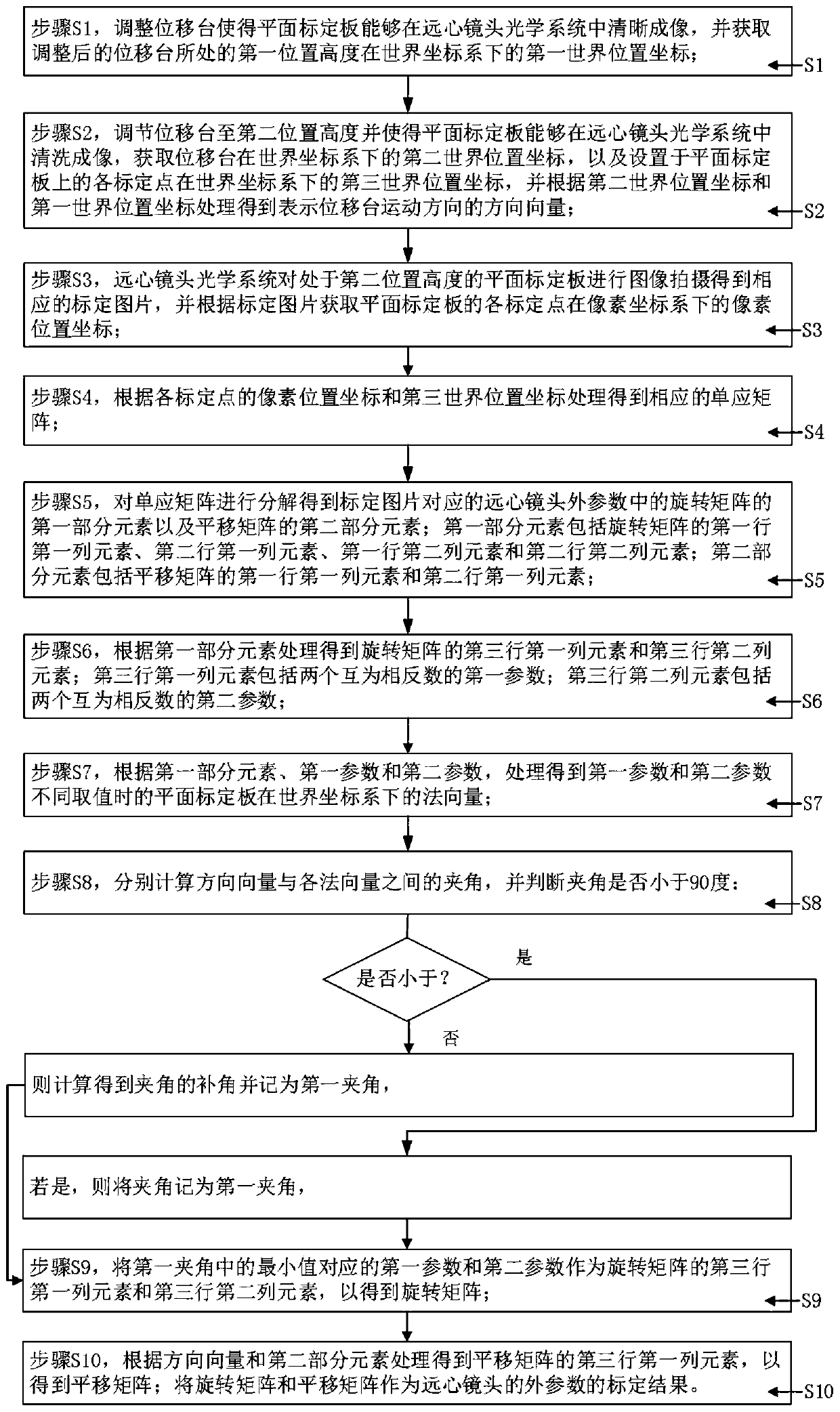

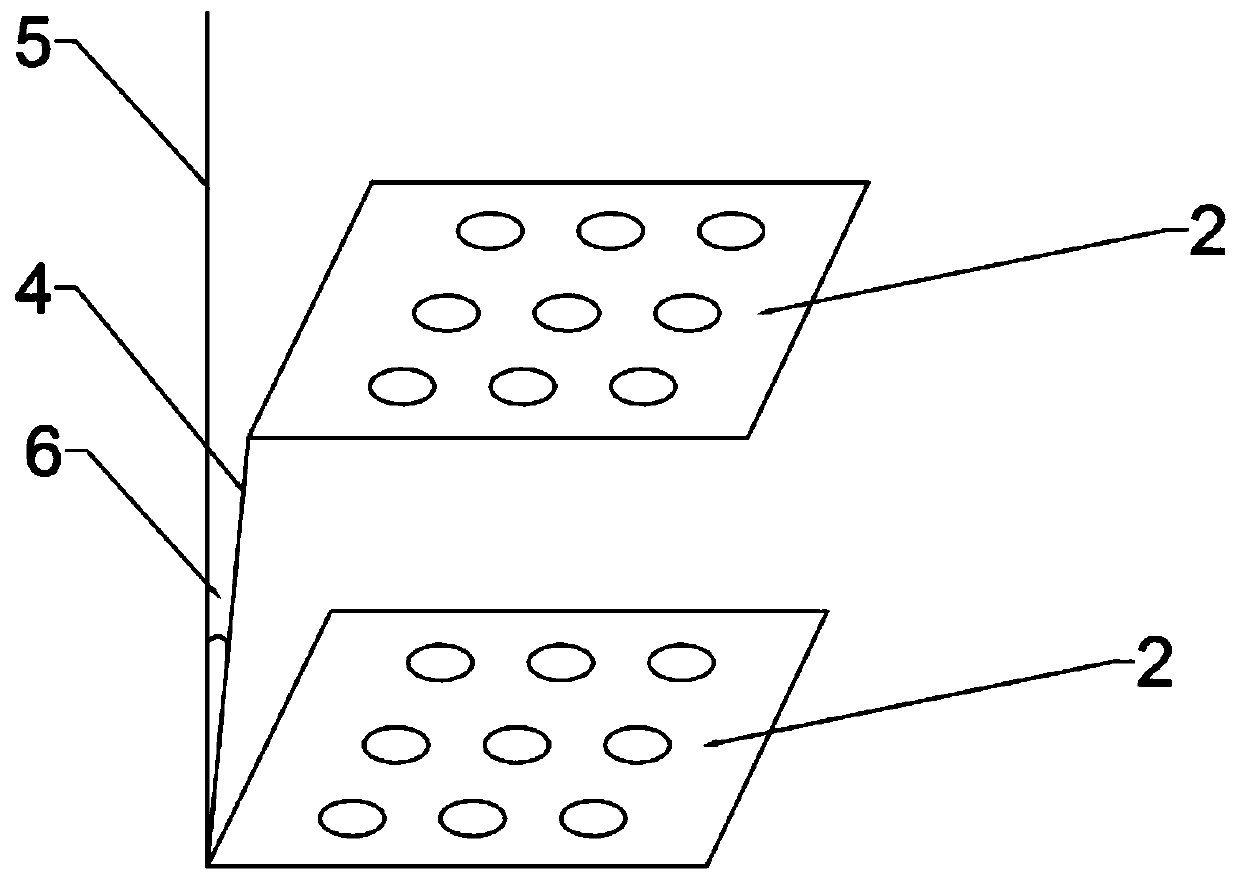

Telecentric lens external parameter calibration method based on normal vector

ActiveCN110490941AAvoid Calibration ErrorsImprove calibration accuracyImage analysisComplex mathematical operationsMatrix decompositionMachine vision

The invention provides a telecentric lens external parameter calibration method based on a normal vector, and relates to the technical field of machine vision application, and the method comprises thesteps: obtaining a first world position coordinate of a displacement platform; adjusting the displacement table to obtain a second world position coordinate and a third world position coordinate of the calibration point, and obtaining a direction vector according to the second world position coordinate and the first world position coordinate; obtaining pixel position coordinates of the calibration points; obtaining a homography matrix according to the pixel position coordinates and the third world position coordinates; decomposing the homography matrix to obtain a first part of elements and asecond part of elements; performing processing according to the first part of elements to obtain third-row first-column elements and third-row second-column elements; obtaining a normal vector of theplane calibration plate according to the rotation matrix; calculating an included angle between the direction vector and each normal vector, and taking a parameter corresponding to a minimum value inthe included angles as other elements of the rotation matrix; and performing processing according to the direction vector and the second part of elements to obtain other elements of the translation matrix. The calibration precision and stability are effectively improved.

Owner:苏州深浅优视智能科技有限公司

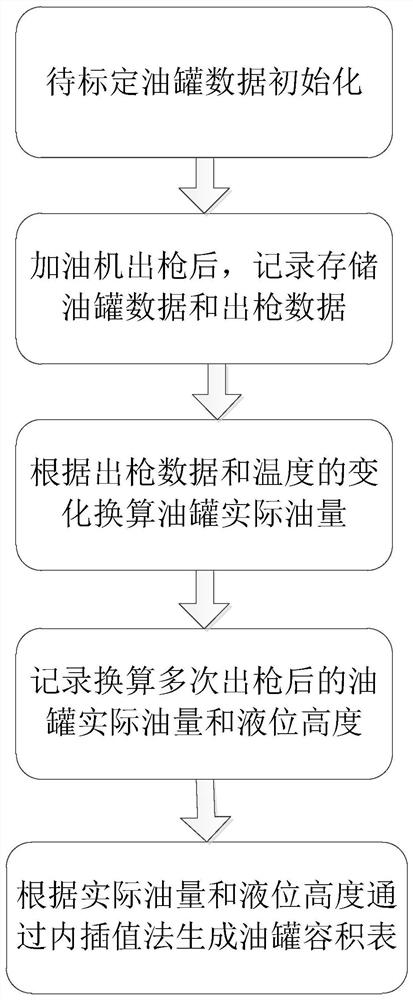

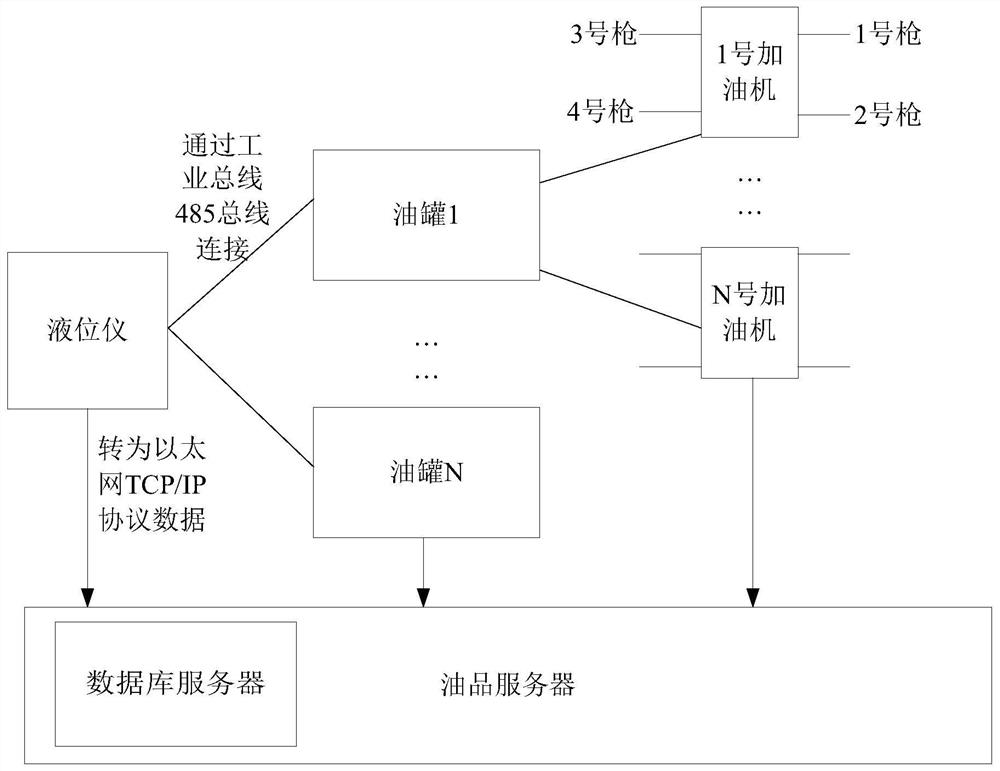

Gas station oil tank volume table calibration method

PendingCN112461336AImprove convenienceImprove accuracyTesting/calibration for volume measurementPetrol stationOil temperature

The invention discloses a method for calibrating an oil tank volume table of a gas station. The method comprises the following steps of initializing to-be-calibrated oil tank data; after the oiling machine discharges the gun, recording oil storage tank and gun discharge data; converting the actual oil quantity of the oil tank according to the gun-out data and the temperature change; recording andconverting the actual oil quantity and the liquid level height of the oil tank after multiple times of gun discharging; and generating an oil tank volume table through an interpolation method according to the actual oil quantity and the liquid level height. According to the method, the volume meter of the oil tank is calibrated by adopting a mode of oiling and discharging oil by the oil gun, so convenience of calibrating the volume meter of the oil tank is greatly improved; and meanwhile, in the calibration process of the volume meter, the influence of the oil temperature on the volume changeis considered, the calibration error caused by the oil temperature change is overcome, and calibration accuracy of the oil tank volume meter is improved.

Owner:王刚 +1

A device for calibration of tension and compression residual stress

ActiveCN106153458BEasy to operateAchieving Stress CalibrationMaterial strength using tensile/compressive forcesStress measurementEngineering

The invention discloses a device for calibrating tension and compression type residual stress, and belongs to the technical field of experimental stress measurement in a process of material processing. The device comprises a tension and compression loading mechanism, a clamping mechanism and a supporting mechanism. The tension and compression loading mechanism applies uniform tensile or compressive stress in all the thickness directions of a calibration material; the clamping mechanism can adjust a clamping position according to the tension and compression type of the calibration material; the supporting mechanism is provided with the tension and compression loading mechanism and the clamping mechanism, and can automatically adjust the height. The device can be used as a matched loading device for a blind hole method, an indentation strain method and other residual stress detection methods, and accurately calibrates the material stress-strain relationship in a tensile stress state and in a compressive stress state; besides, the device is simple and flexible to operate and convenient to use, and overcomes the problems that a device is convenient and easy to use but a stress field is nonuniform during three-point bending loading, or the problems that large-size samples are required and loading is not easy during calibration with a tensile test machine.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com