Mounting parameter calibration method for vehicular camera of driving assistant system

A technology for driving assistance systems and installation parameters, applied in image data processing, image analysis, instruments, etc., can solve problems such as inconvenient operation, camera tolerance, inaccurate calibration results, etc., to achieve low equipment and equipment costs, and avoid calibration errors. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

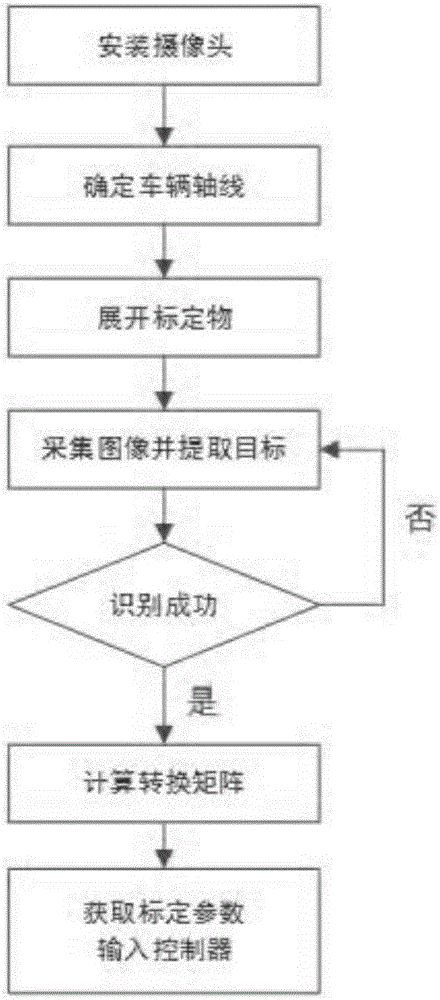

[0043] Such as figure 1 As shown, the specific operation is as follows:

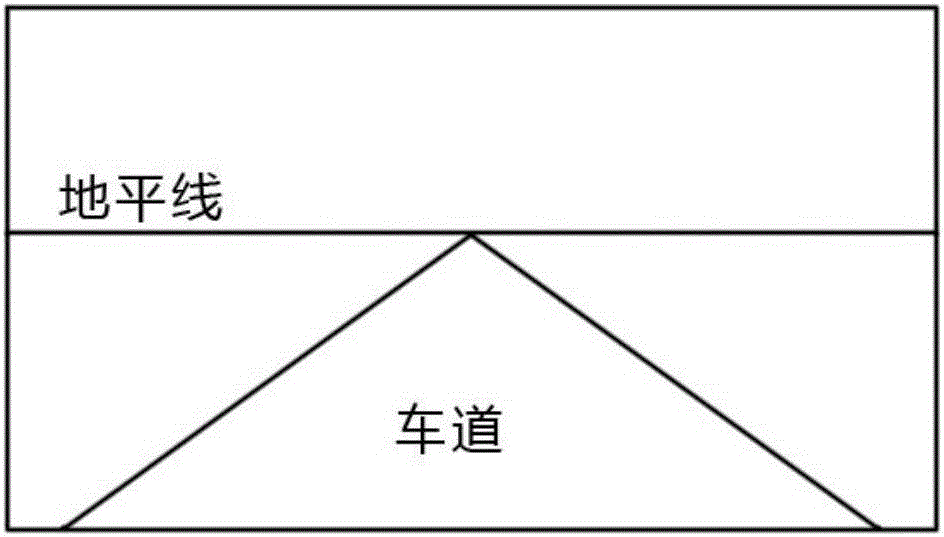

[0044] 1. Determine the installation position and angle of the camera. Adjust the horizon line in the picture to a suitable position, such as figure 2 , so that the horizon remains horizontal in the frame. The preferred position of the camera is in the middle of the car, and the height from the ground can be adjusted according to the vehicle model. The recommended distance is 1.2-1.5m for small vehicles and 1.5-2.2m for large vehicles such as trucks.

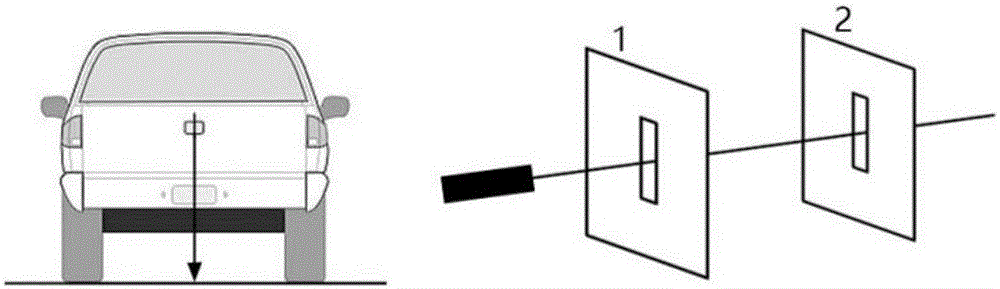

[0045] 2. Determine the position of the central axis at the front and rear of the vehicle through features such as the fixed point of the vehicle license plate, and use the plumb bob to extend the midpoint to the ground plane.

[0046] Determine the centerline of the vehicle using auxiliary bulkheads and a laser p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com