Device for detecting gas production rate of cylindrical lithium ion battery and application method thereof

A lithium-ion battery and gas production technology, applied in the field of lithium-ion batteries, can solve the problems of affecting the gas discharge of the lithium-ion battery, the sound electrolyte, unsuitable for sampling the gas production of the lithium-ion battery, inaccurate and inaccurate battery gas production, etc. Small deformation, long service life and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

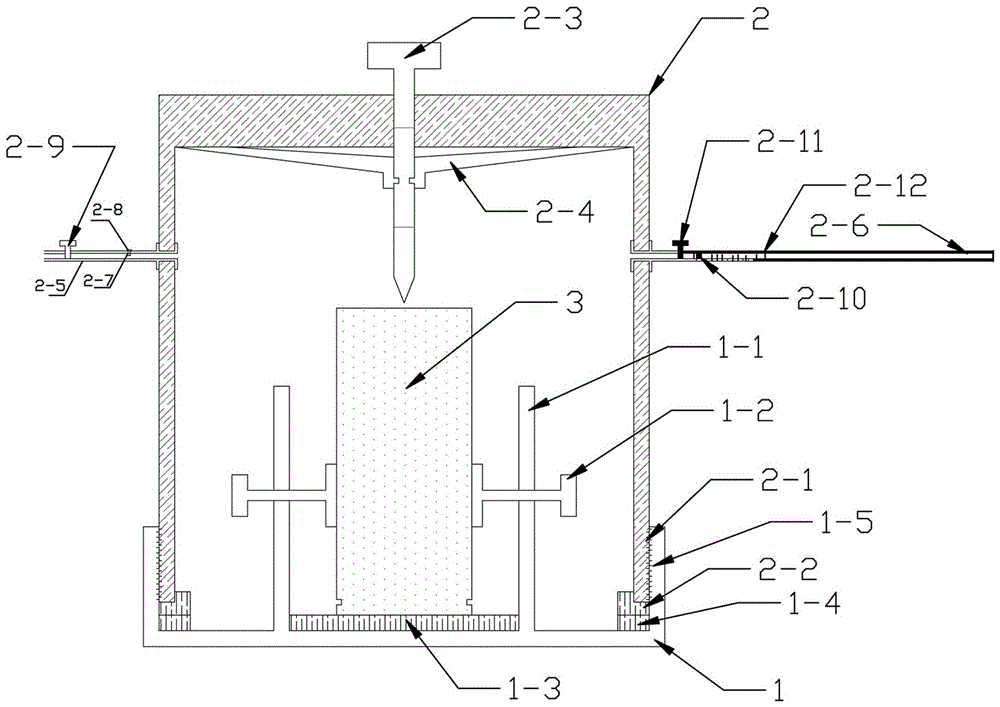

[0043] The device for detecting the gas production of a cylindrical lithium-ion battery is mainly composed of a circular base 1 and an upper cavity component 2. The shell walls of the base 1 and the upper cavity component 2 are made of stainless steel. The base 1 is fixed with a battery fixing groove 1-1, a battery Locating pin 1-2, battery insulating pad 1-3, base 1 bonded lower sealing pad 1-4, internal thread on the inner wall of the base, and corresponding external thread on the outer wall of the opening of the upper cavity assembly 2. The opening end of the upper cavity assembly 2 is bonded with an upper gasket 2-2 corresponding to the lower gasket 1-4 of the base. A steel needle 2-3 is arranged on the top of the upper cavity assembly 2, and the steel needle 2-3 is located at the center of the upper cavity assembly, passes through the shell wall of the upper cavity assembly, and can move up and down. The inner top of the upper cavity assembly is sealed with the steel need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com