Calibration device for inclination angle sensor

A technology of inclination sensors and calibration devices, which is applied in the direction of measuring devices, instruments, etc., can solve problems such as inability to meet needs, and achieve the effect of overcoming inaccurate zero point positions and overcoming calibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

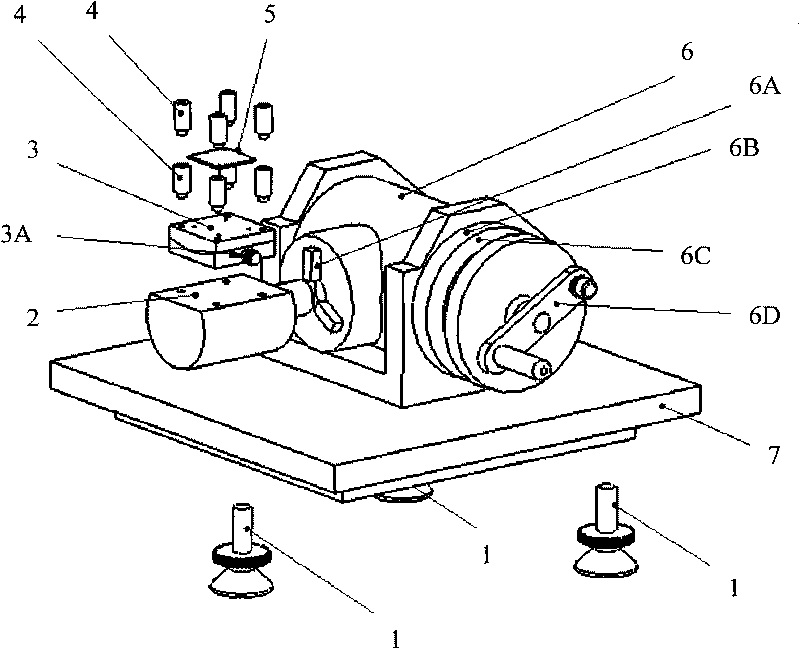

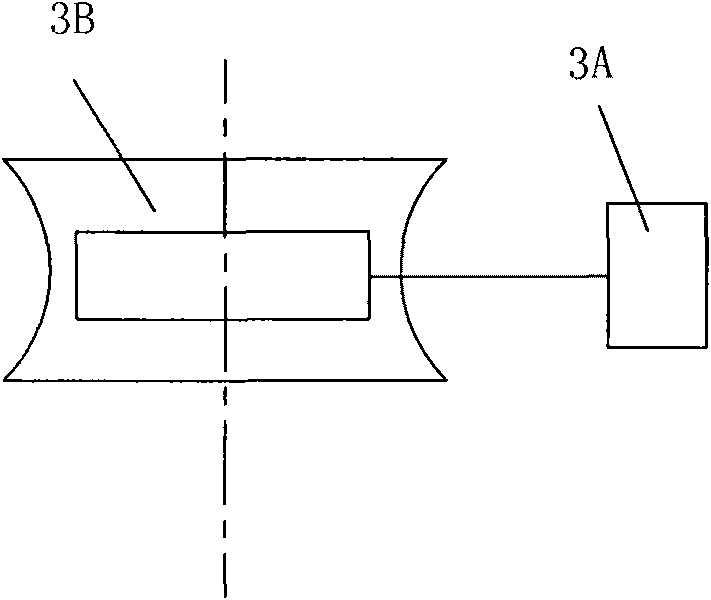

[0019] see figure 1 , an indexing head 6 is arranged on the base 7 that can be adjusted to be horizontal, and the three-jaw chuck 6A fixedly connected to the side of the indexing head 6 clamps the sensor holder 2; the angular displacement table 3 is installed on the sensor holder 2 , the sensor 5 to be calibrated is installed on the angular displacement stage 3 through the sensor fixture 4;

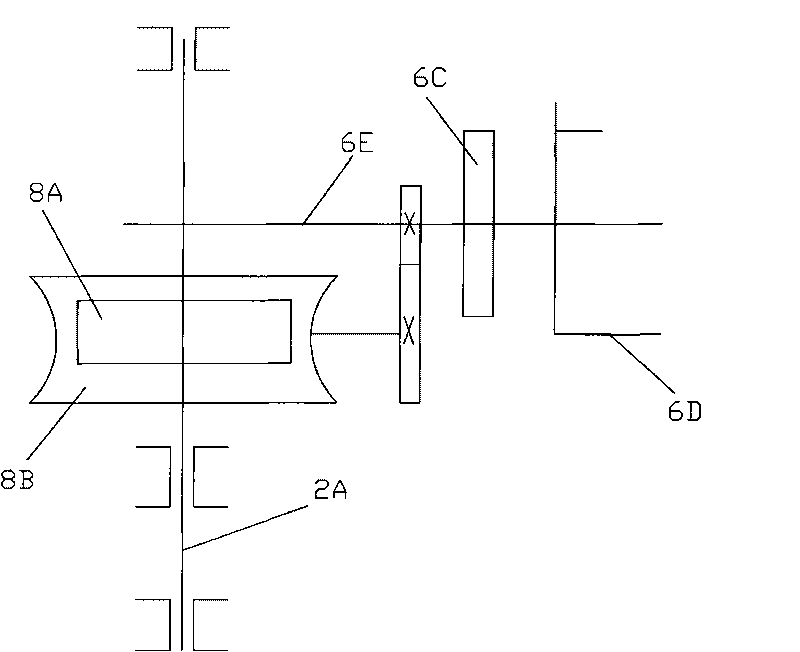

[0020] Indexing head 6 is a rotatable member with a horizontal rotating shaft, and is fixedly connected with a rotating handle 6D at the shaft end of indexing head horizontal rotating shaft 6E. The angle code disc 6C measures the rotation angle of the sensor fixing frame 2, and the sensor fixing frame rotating shaft 2A and the rotating shaft of the indexing head 6 are arranged at 90 degrees in the horizontal plane.

[0021] In specific implementation, the internal transmission structure of the dividing head 6 is as follows: figure 2 As shown, the rotating handle 6D is used to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com