Vision-based robot automatic calibration method, equipment and storage medium

An automatic calibration and robot technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as troublesome and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

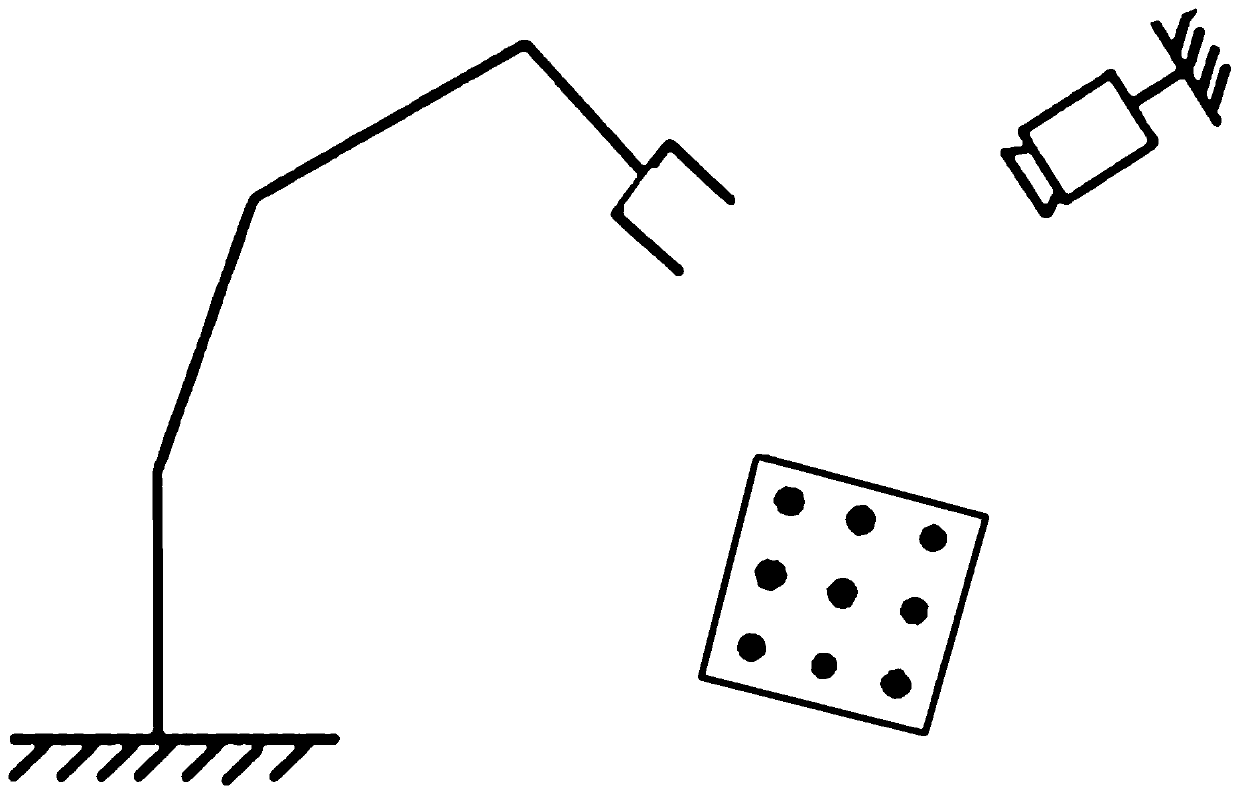

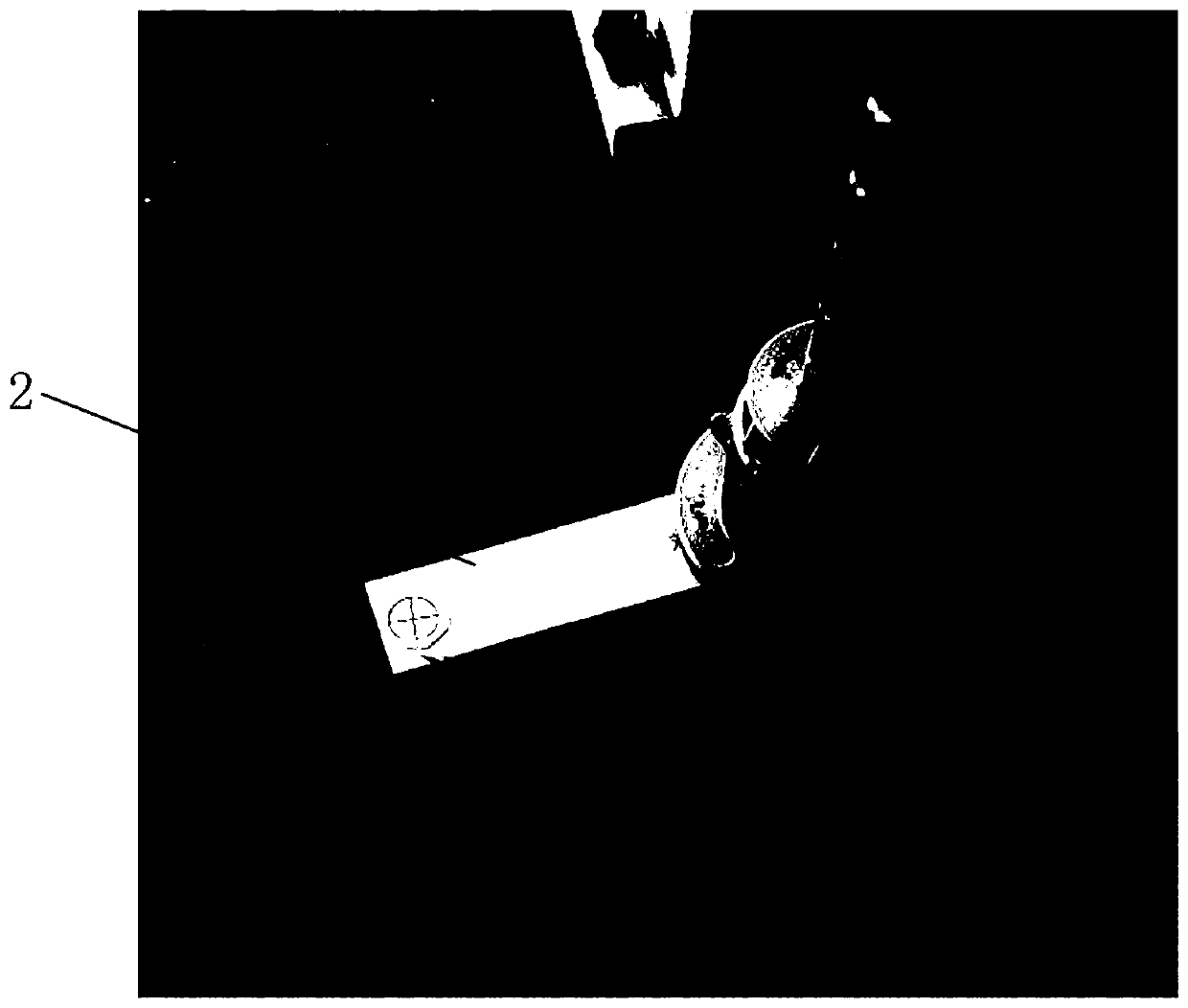

[0045] This embodiment discloses a vision-based automatic calibration method for a robot. The calibration method needs to use a robot, a camera and a MARK point. The MARK point is fixed at the end of the robot (that is, the action execution end of the robot), refer to figure 2 As shown, the MARK point "+" is set on the marking plate 2, and the marking plate 2 is installed at the end of the robot. In actual use, the marking plate 2 can be fixed at the end of the robot by pasting or negative pressure adsorption. Among them, the MARK point is set according to the requirement that it is at the same level as the detected workpiece. The position of the above-mentioned camera is fixed, and the movement of the above-mentioned robot makes the MARK point move in the camera field of view. The above-mentioned camera is used to observe the attitude of the MARK point and record the pixel coordinates of the MARK point in the camera coordinate system.

[0046] After introducing the MARK poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com