Positioning clicking device and method and touch display screen calibration system and method

A technology of touch display screen and calibration system, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve the problems of low accuracy and low efficiency of touch screen display, so as to improve accuracy and implement The effect of high efficiency and avoiding calibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

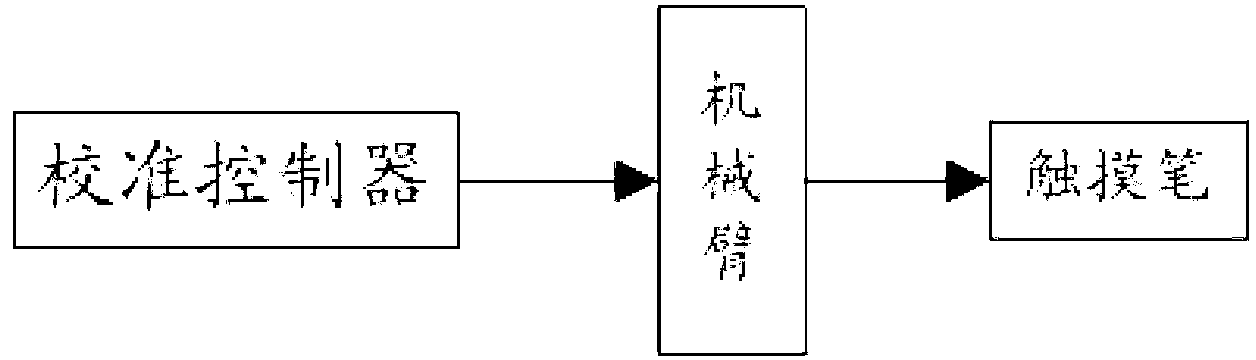

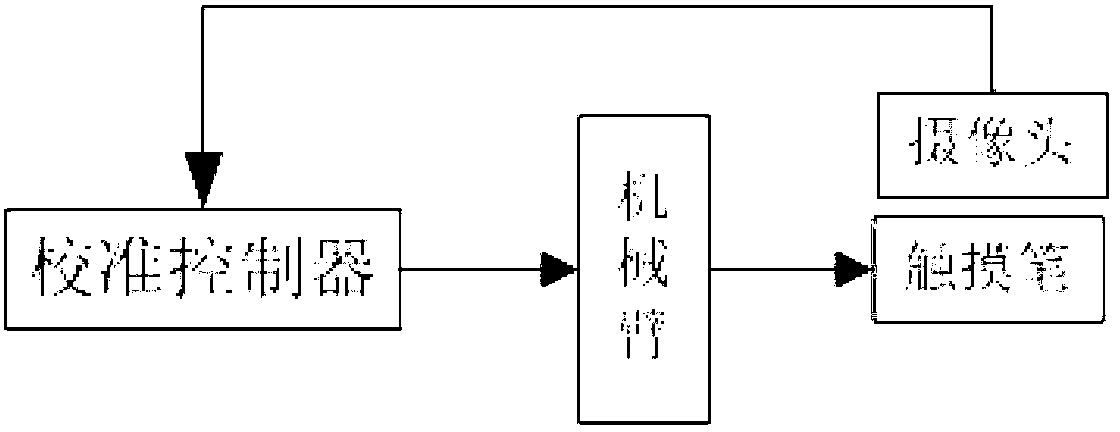

[0059] The touch screen calibration system provided in this embodiment includes a positioning and clicking device, and the positioning and clicking device is as follows: figure 1 Shown, including calibration controller, robotic arm, and stylus. The mechanical arm can be an existing three-axis driven mechanical arm capable of moving in the X, Y, and Z axes. The calibration controller controls the mechanical arm to drive the touch pen to move above the display screen under test. After precise positioning Use the center of the stylus to click the center of the coordinate point (also called the calibration point) displayed on the display screen under test, such as the center point of the cross coordinate point and the center of the circular coordinate point; the operator can control the machine through the calibration controller The arm, or the calibration controller can capture the position image of the center of the calibration point through an external camera, calculate the off...

Embodiment 2

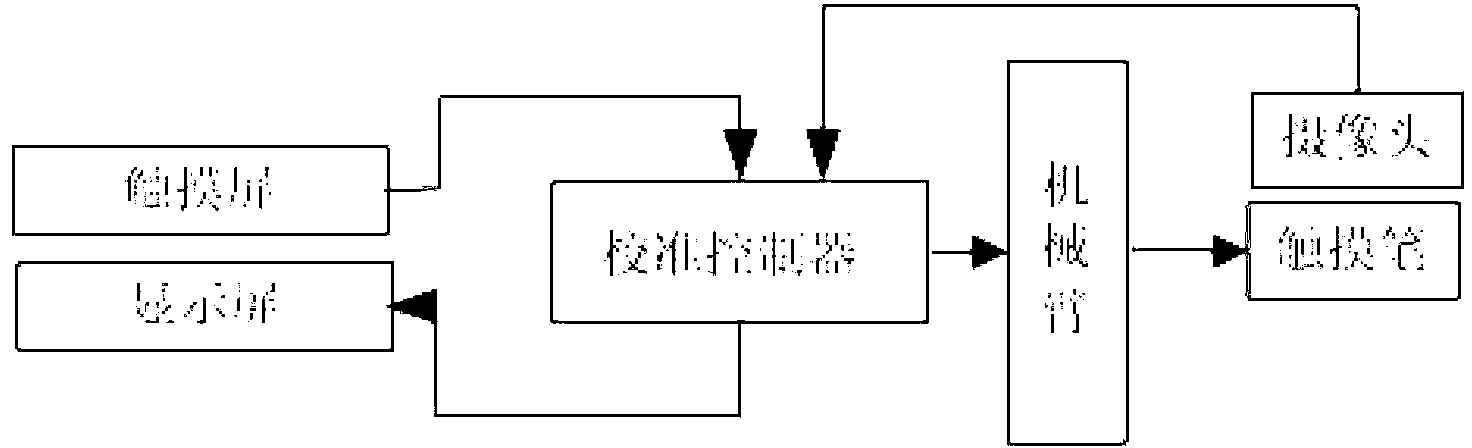

[0062] In this embodiment, the calibration controller not only can control the positioning and clicking of the touch pen on the mechanical arm, but also has the calibration function of the touch screen.

[0063] Such as image 3 As shown, the calibration controller in the touch screen calibration system in this embodiment not only controls the connection with the mechanical arm, but also has a port for connecting the touch screen under test and the display screen under test, which is used to directly communicate with the touch screen under test and the display screen. The calibration controller can typically use a computer to connect to the touch screen under test through a connection port such as USB or COM, and to connect and control the display screen under test through interfaces such as VGA, HDMI, and DVI. The storage of the calibration controller The calibration algorithm and I calibration point coordinates (I is an integer greater than or equal to 1) required by the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com