Calibration method and device for optical fiber load sensor of wind generating set

A technology of wind turbines and load sensors, which is applied in the monitoring of wind turbines, wind turbines, mechanical equipment, etc., can solve problems such as time-consuming and labor-consuming, and achieve the effects of avoiding calibration errors, high accuracy, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

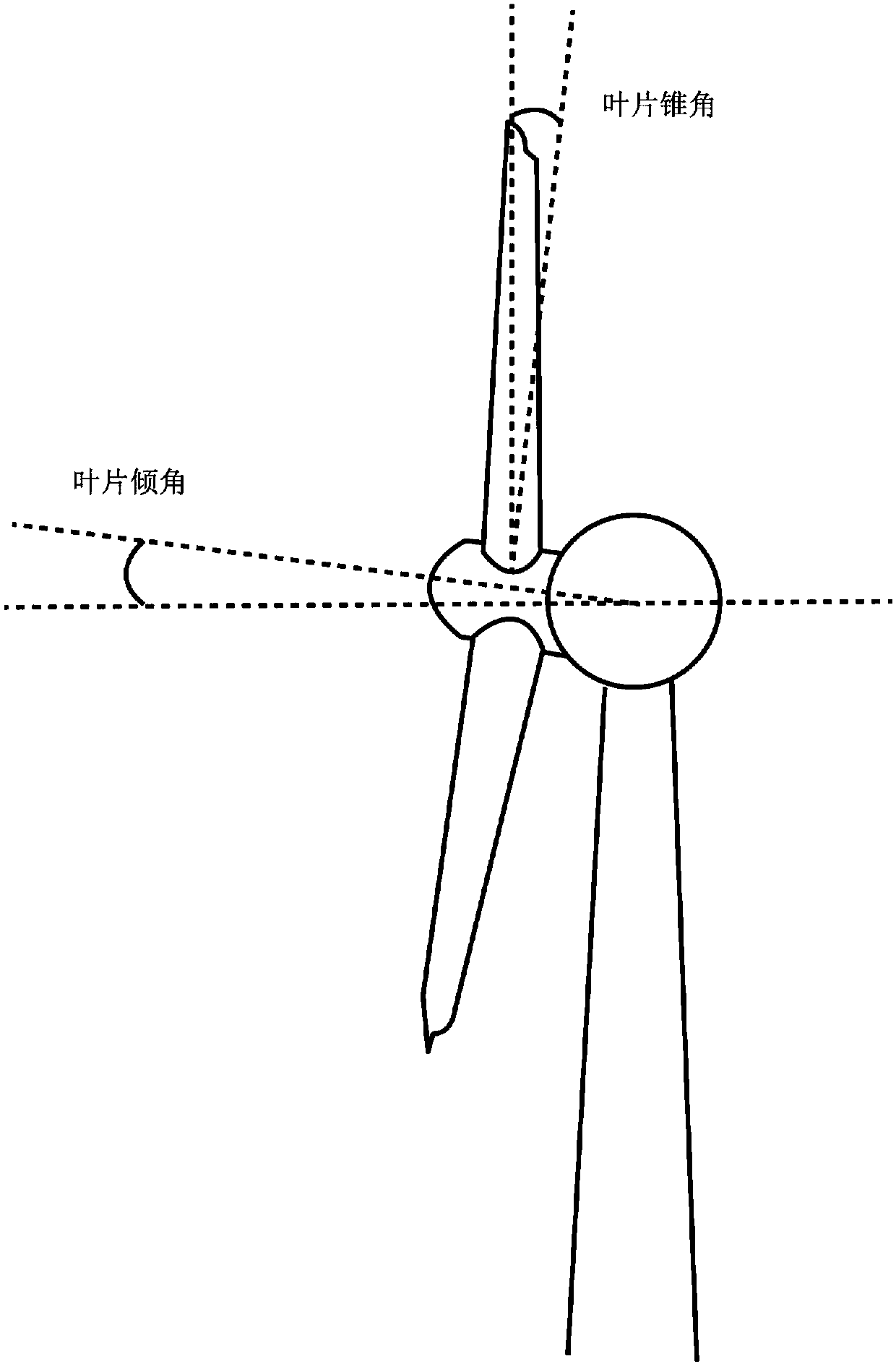

[0037] The following will refer to figure 1 Describe some terms involved in the present invention.

[0038] The load refers to the external force and other factors that cause the internal force and deformation of the structure or component. In the present invention, it refers specifically to the bending moment of the blade root of the wind turbine, including the bending moment in the two directions of the blade flapping direction and the blade shimmy direction.

[0039] The blade flapping direction refers to the direction perpendicular to the chord line; the blade shimmy direction refers to the direction parallel to the chord line.

[0040] The pitch angle refers to the angle between the chord line of the blade and the rotation plane. The pitch angle of the wind turbine is generally around 0° when the wind turbine is in normal operation, and the pitch a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com