Movable-type calibration method for camera parameters of industrial photogrammetry system

A measurement system and industrial photography technology, applied in the field of calibration, can solve problems such as low accuracy, little calibration information, and deviation of optical coordinates, and achieve the effect of avoiding calibration errors and high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A mobile calibration method for camera parameters of an industrial photogrammetry system, comprising the following steps:

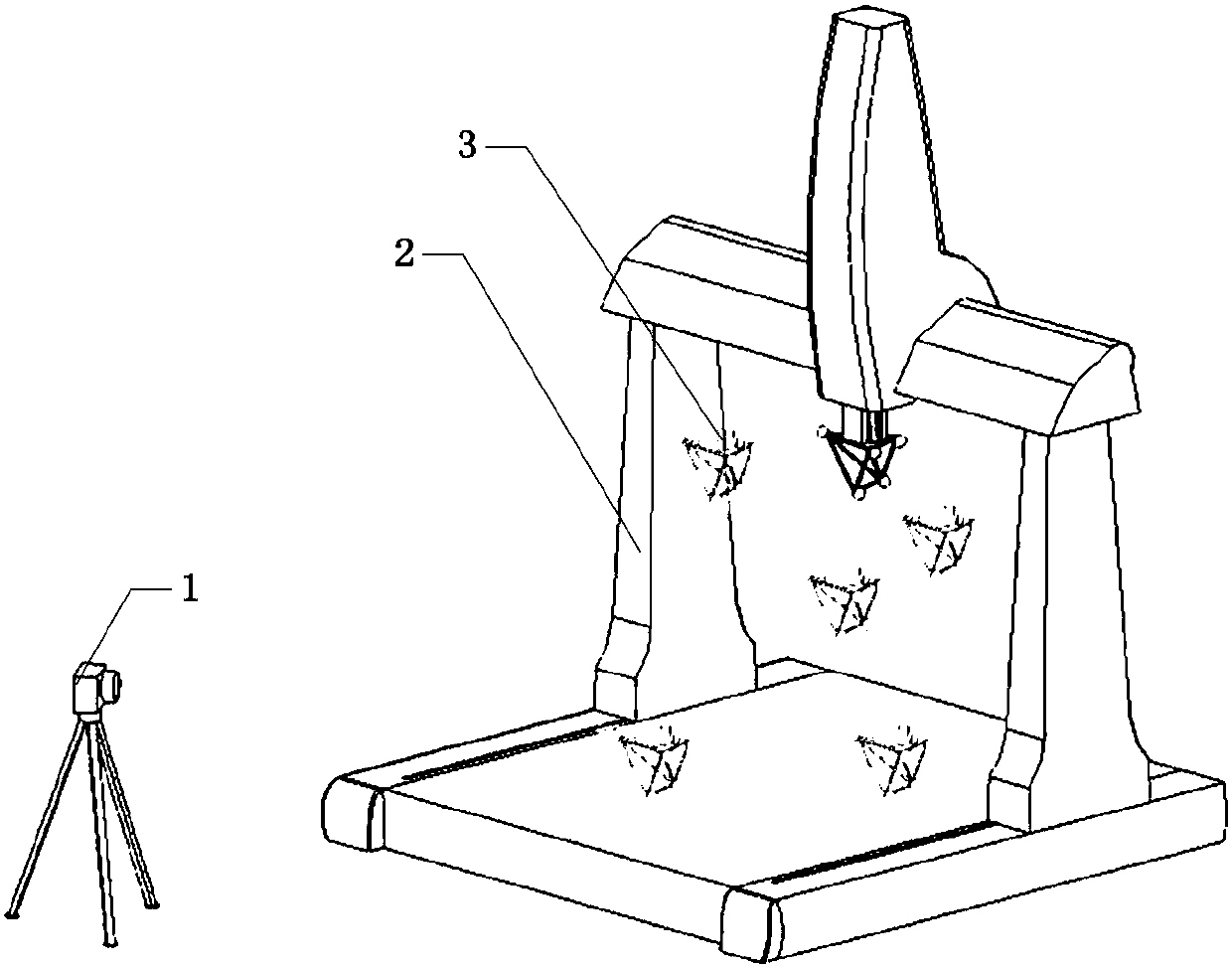

[0027]S1: Select the optical target 3, the optical target 3 must have the optical characteristics that can be recognized by the industrial photogrammetry system 1, such as the use of flat reflective marks, spherical reflective marks, light-emitting LEDs, black and white checkerboard marks, etc. Industrial photogrammetry refers to Two or more images taken from different angles to obtain the three-dimensional geometric information of objects in the scene.

[0028] S2: Construct a three-dimensional motion mechanism, and fix the optical target 3 on the moving part of the three-dimensional motion mechanism, so that the moving part can drive the optical target to perform three-dimensional translational motion. It is fixed on the probe of the three-coordinate measuring machine, and the probe of the three-coordinate measuring machine drives the optical tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com