Winding device for banding pipes

A winding device and pipe material technology, applied in the direction of packaging/bundling items, packaging, transportation and packaging, etc., can solve the problems of poor bundling effect, low degree of equipment automation, waste of bundling film, etc., to achieve a stable bundling process and avoid noise , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

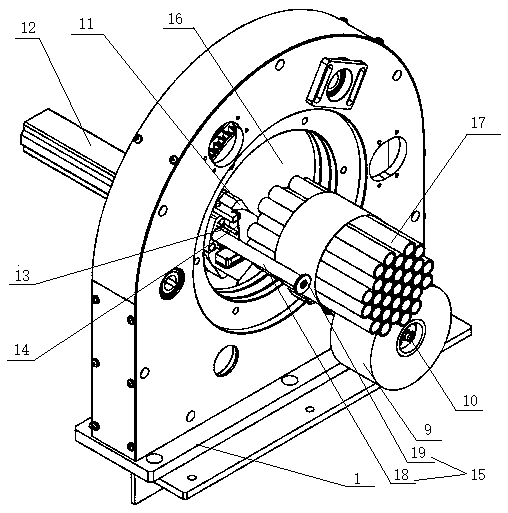

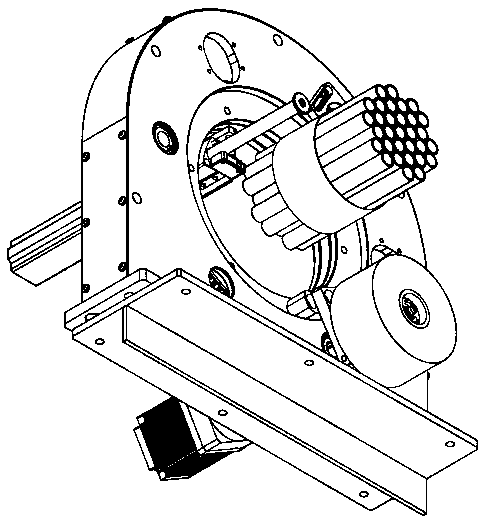

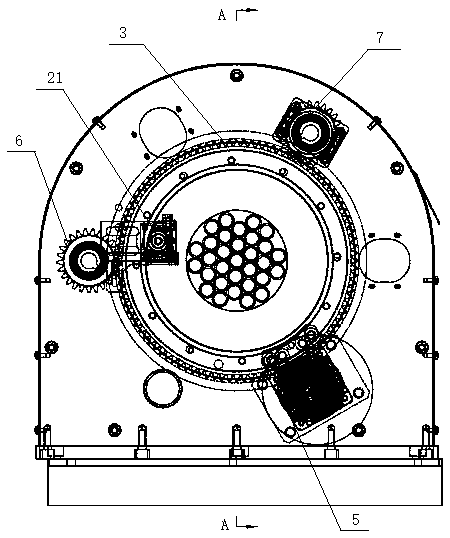

[0022] like Figure 1 to Figure 5 As shown, a pipe bundling and winding device is used for winding a bundling film 9 on a pipe 17, including a bundling fixed seat 1 and a film pulling device 21 located above the bundling fixed seat 1 and used for winding a bundling film for a pipe. Two annular positioning plates 2 arranged side by side are installed on the fixed seat 1, a driven rotating gear 3 is arranged in the middle of the two annular positioning plates 2, and two inclined surfaces 4 are formed at the ends of the two annular positioning plates, so that The outer circumference of the driven rotating gear 3 is evenly provided with three gears meshing with it, which are respectively the driving gear 5 located at the lower right of the driven rotating gear, the fixed positioning gear 6 on the left side and the adjustable positioning gear 7 at the upper right. The driving gear 5 is driven to rotate by the motor 20, and the driven rotating gear 3, the fixed positioning gear 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com