Toner cartridge scraper and manufacturing method thereof

A manufacturing method and scraper technology, which are applied in the fields of electrical recording, optics, instruments, etc., can solve the problems of batch degumming, the film is easy to fall off, and the firmness is not good, so as to ensure product quality, improve fastness, and not easy to fall off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

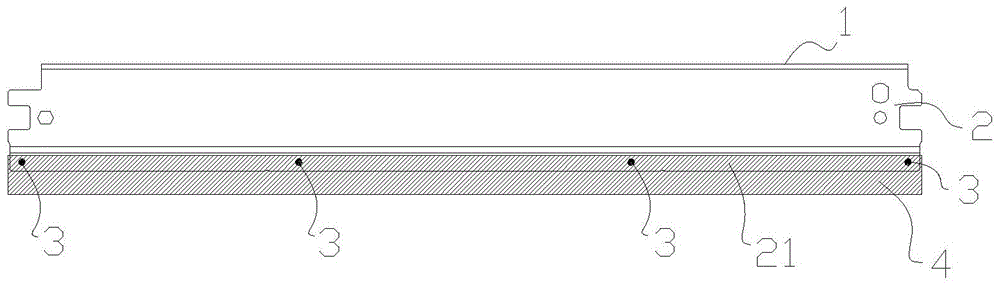

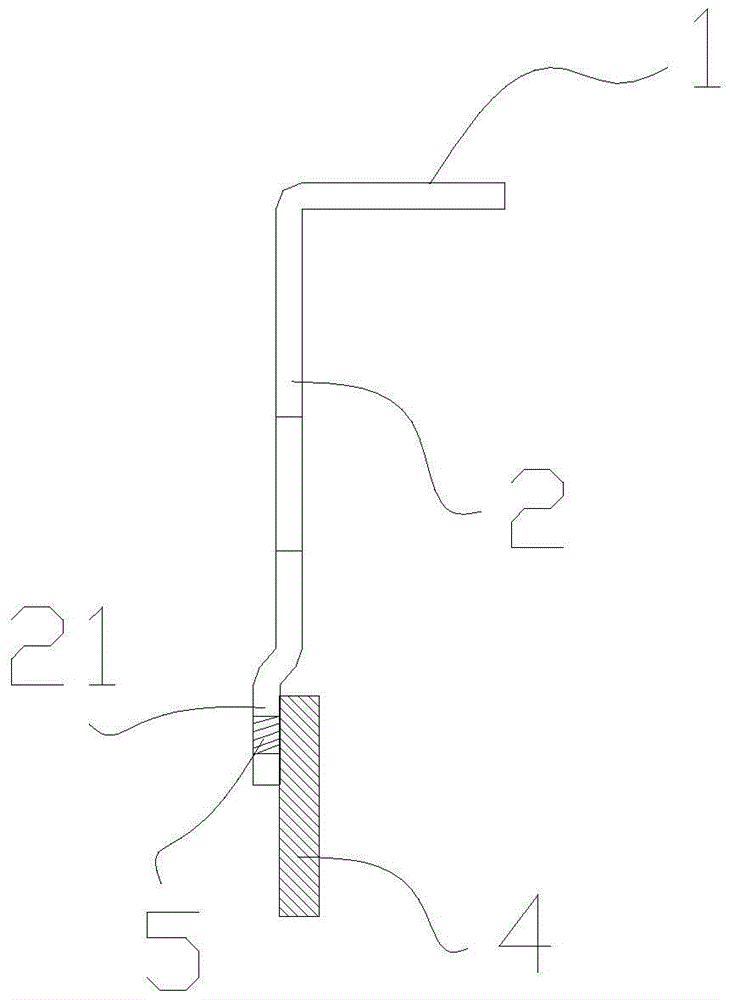

[0020] refer to Figure 1 to Figure 3 , the embodiment of the present invention provides a toner cartridge scraper, including a bracket 1, the bracket 1 has an L-shaped cross section, and a plurality of sticking reinforcement holes 3 are opened on the step surface 2 of the bracket 1, and the sticking reinforcement holes 3 are 1.7 mm in diameter. Circular perforation; in the present embodiment, on the step surface 2 of support 1, four pasting reinforcement holes 3 are arranged, and the distance between the center of the pasting reinforcement holes 3 at both ends of support 1 and the two ends of support 1 is 3mm, the second The hole distance between one paste reinforcement hole 3 and the second paste reinforcement hole 3 is 70mm, the hole distance between the second paste reinforcement hole 3 and the third paste reinforcement hole 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com