TYYH-type drain wire clamp

A technology of drainage wire clamp and drainage plate, which is applied in the direction of multi-conductor connectors, electrical components, connections, etc., can solve problems such as difficulty in crimping drainage wires and conductors, burning out construction of drainage plates, and affecting sag changes, etc., and achieves a solution The effects of burning out and construction left over false leads, reducing line tripping, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

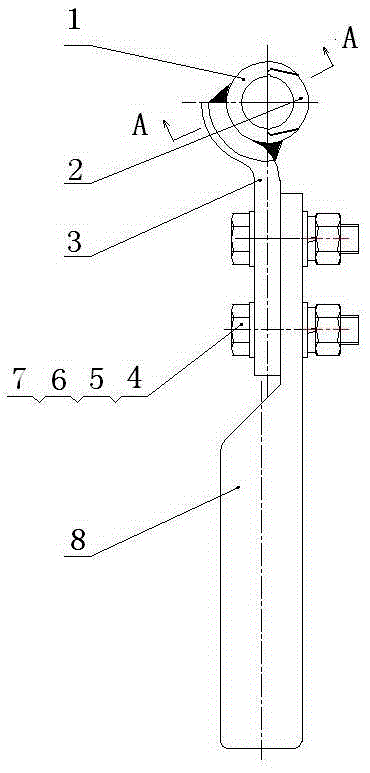

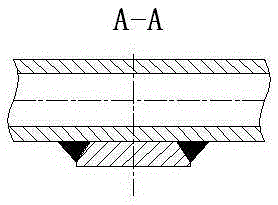

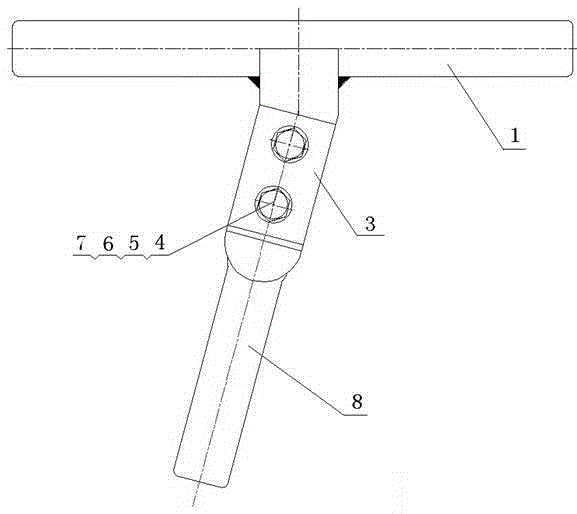

[0014] like Figure 1-7 As shown, a TYYH type drainage clip includes a repair pipe body 1, the outer surface of the repair pipe body 1 is connected to a drainage plate 3, and the drainage plate 3 is located in the middle of the length direction of the repair pipe body 1. The drainage plate 3 is connected with the drainage clamp 8, and the main body 1 of the repairing pipe is matched with the drawer 2 of the repairing pipe. The outer surface of the repair pipe main body 1 is connected with the drainage plate 3 by welding. The drain plate 3 is connected with the drain clamp 8 through the hex head bolt 4 , the hex nut 5 , the flat washer 6 and the spring washer 7 .

[0015] Use the present invention, can obtain following effect:

[0016] 1) The original connection method is not changed, and the original wires and fittings are not replaced.

[0017] 2) The problem wire jumper can be permanently processed and restored.

[0018] 3) After the implementation, the number of infrare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com