Variable ducted propeller

A technology of ducted propellers and propellers, which is applied in shipbuilding, ship propulsion, ships, etc., can solve the problems of low propulsion efficiency and decrease of propulsion efficiency, and achieve the effect of improving propulsion efficiency and high propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

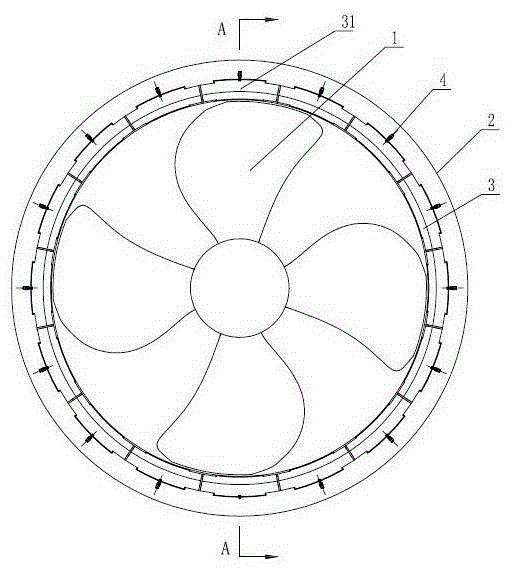

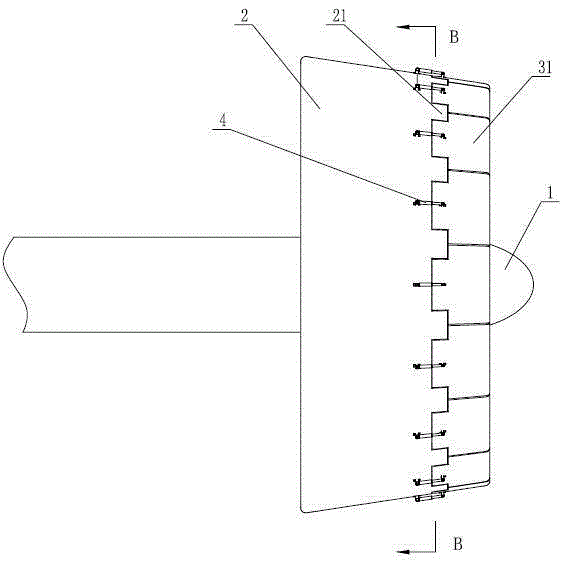

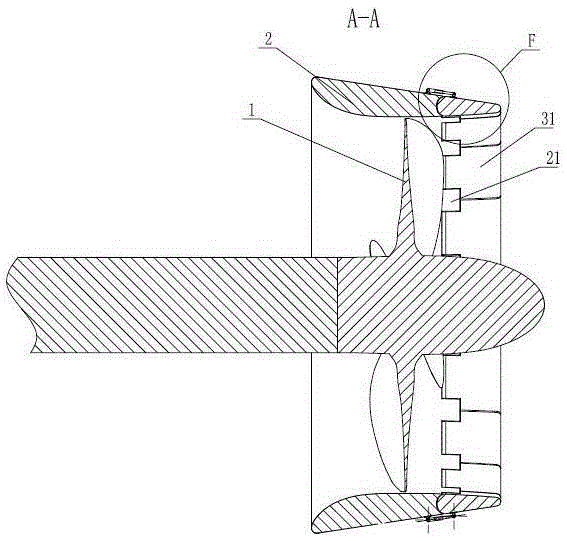

[0023] See figure 1 , figure 2 , image 3 , Figure 4 , the present invention includes a propeller 1 and a conduit sleeved on the periphery of the propeller 1, the conduit includes a fixed pipe section 2 and a movable pipe section 3 connected in series along the axial direction of the propeller 1, and the fixed pipe section 2 and the movable pipe section 3 are both annular sleeve structures , the fixed pipe section 2 is located at the front end of the conduit; the front end refers to the shaft of the propeller 1 and one end of the gearbox, and the gearbox transmits power to the shaft of the propeller 1; the movable pipe section 3 is composed of a plurality of The vanes 31 are connected in series along the circumferential direction, and the vanes 31 are rotatably connected to the end surface of the fixed pipe section 2. The outer wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com