Bevel gear transmission torque self-balancing shaftless ducted fan or propeller blades for aircraft

A technology for ducted fans and aircraft, which is applied in the field of bevel gear transmission torque self-balancing shaftless ducted fans or shaftless ducted blades for aircraft, which can solve the problem of large air circulation space in the hub, increased blade tip linear velocity, and reduced efficiency and other issues, to achieve the effect of reducing disturbance and wind resistance, reducing disturbance turbulence, and improving lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

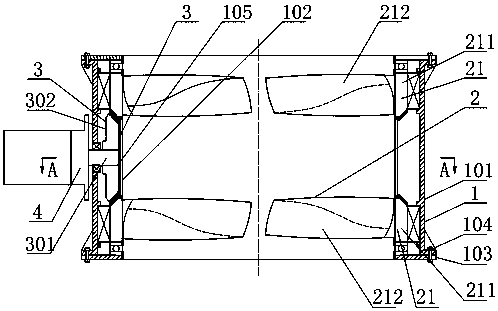

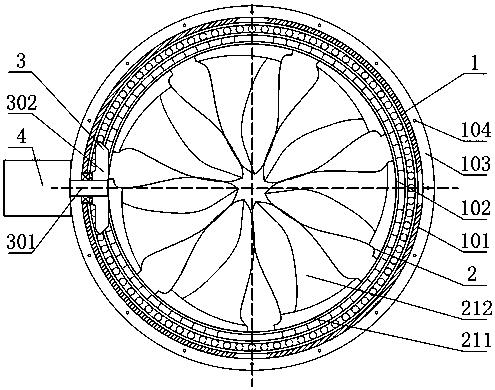

[0031] refer to figure 1 and figure 2 , a self-balancing shaftless ducted fan with bevel gear transmission torque for an aircraft, comprising a ducted cylinder frame 1, a group of reverse shaftless fans 2 and a transmission mechanism 3, and the reverse shaftless fan 2 and the transmission mechanism 3 are installed In the duct holder 1, the transmission mechanism 3 is connected with the reverse shaftless fan 2 through gears to form a shaftless ducted fan.

[0032] The duct holder 1 includes a duct holder 101, a duct inner cylinder 102 and an annular end cover 103. The duct holder 101 is a mounting bracket for the reverse shaftless fan 2 and the transmission mechanism 3. The annular end cover 103 It is connected with the end of the duct frame 101 through connecting bolts 104, and is used to fix the reverse shaftless fan 2 and prevent it from sliding axially.

[0033] The set of reverse shaftless fans 2 includes two shaftless fans 21 that can rotate in reverse, and the shaftle...

Embodiment 2

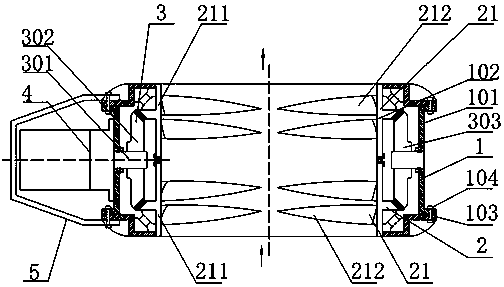

[0040] refer to image 3 , a self-balancing shaftless ducted fan with bevel gear transmission torque for aircraft, the main difference from Embodiment 1 is that this embodiment uses annular angular contact bearings instead of radial bearings and axial bearings as the reverse shaftless fan 2 Install the bracket, and the annular end cover 103 is welded and folded at this time;

[0041] The two toothed cylindrical swivels 211 of the reverse shaftless fan 2 of the present embodiment are T-shaped rings, and the surface near the fan port of the toothed cylindrical swivel 211 is connected with the annular end cover 103 through the annular angular contact bearing, the gear It meshes with the main bevel gear 302, and at the same time, two toothed cylindrical swivels 211 are connected by plane bearings to form the duct inner cylinder 102;

[0042] The blades 212 of this embodiment are of two stages, and are evenly fixed on the inner surface of the toothed cylindrical swivel 211;

[00...

Embodiment 3

[0046] refer to Figure 4 , a self-balancing shaftless ducted fan with bevel gear transmission torque for an aircraft, the main difference from Embodiment 1 is that the toothed swivel of this embodiment is a toothed annular swivel 221, and it is also provided with a power unit 4 synchronous The second power unit 4' in operation, the second power unit 4' drives the toothed annular swivel 221 through the transition bevel gear 303 that is symmetrical with the main bevel gear 302 to provide more sufficient power and increase the power of the shaftless ducted fan for the aircraft The installation position of the power unit 4 and the second power unit 4' is also provided with a swing device 5, the swing device 5 is connected with the duct frame 101, and the shaftless ducted fan of the aircraft can be adjusted by synchronously rotating the swing device 5. Lift direction, realize the control of aircraft speed;

[0047] Each shaftless fan 21 of this embodiment is also provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com