Hydraulic design method of torispherical pump body for nuclear main pump

A technology of hydraulic design, nuclear main pump, applied in the direction of components, pumps, pump elements, etc. of pumping devices for elastic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

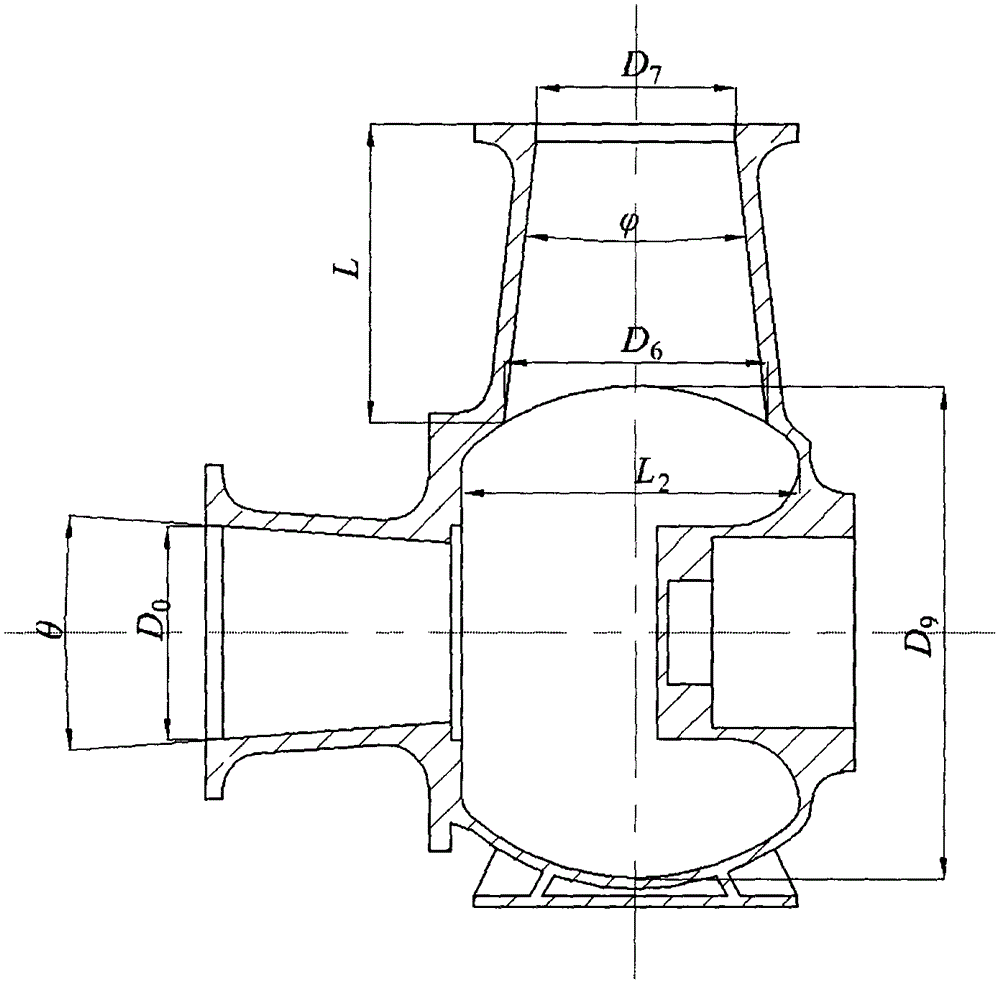

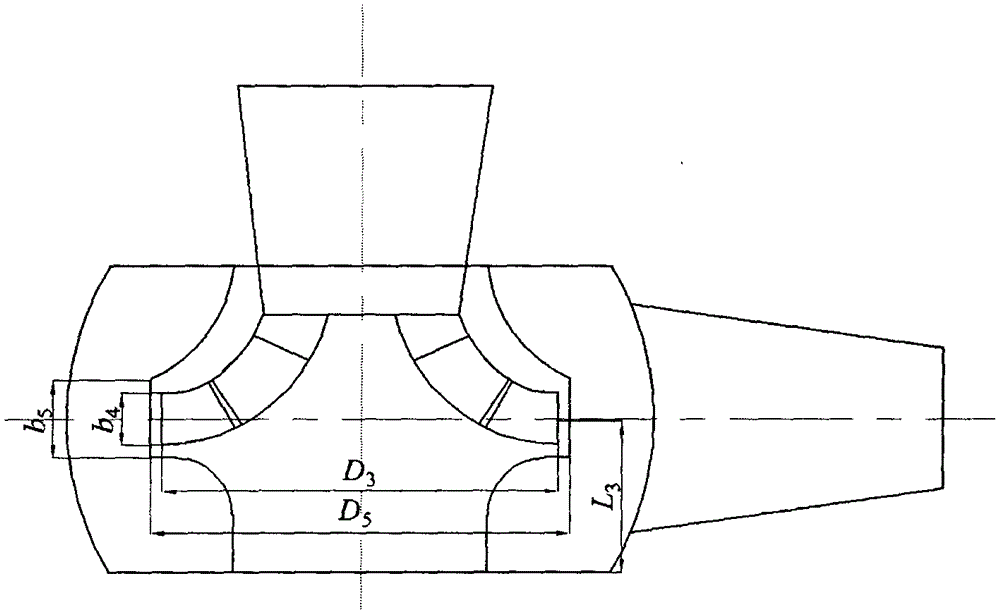

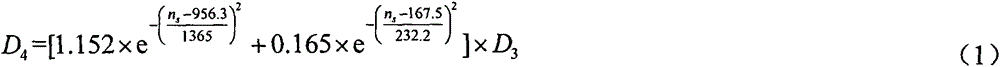

[0107] The present invention uses the following formulas to determine the estimated base circle diameter D of the quasi-spherical pump body for the nuclear main pump 4 、The base circle diameter of quasi-spherical pump body for nuclear main pump D 5 , The inlet width of the quasi-spherical pump body for the nuclear main pump b 5 , Estimated cross-sectional area F of quasi-spherical pump body for nuclear main pump 3 , The cross-sectional area F of the quasi-spherical pump body for the nuclear main pump, the average velocity v of the cross-section of the quasi-spherical pump body for the nuclear main pump, the estimated maximum outer diameter D of the quasi-spherical pump body for the nuclear main pump 8 、Maximum outer diameter D of quasi-spherical pump body for nuclear main pump 9 , The cross-sectional width of the quasi-spherical pump body for the nuclear main pump L 2 、The inlet position L of the quasi-spherical pump body for the nuclear main pump 3 , The inlet diameter D of the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com