Water purification machine system with pressure-limiting stop valve

A technology of stop valve and pure water machine, which is applied in the directions of water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the high pressure of source water and the safety hazard of the pure water machine system , Increase the cost of the pure water machine system and other issues, to achieve the effect of improving the pressure safety performance, saving costs, and facilitating installation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

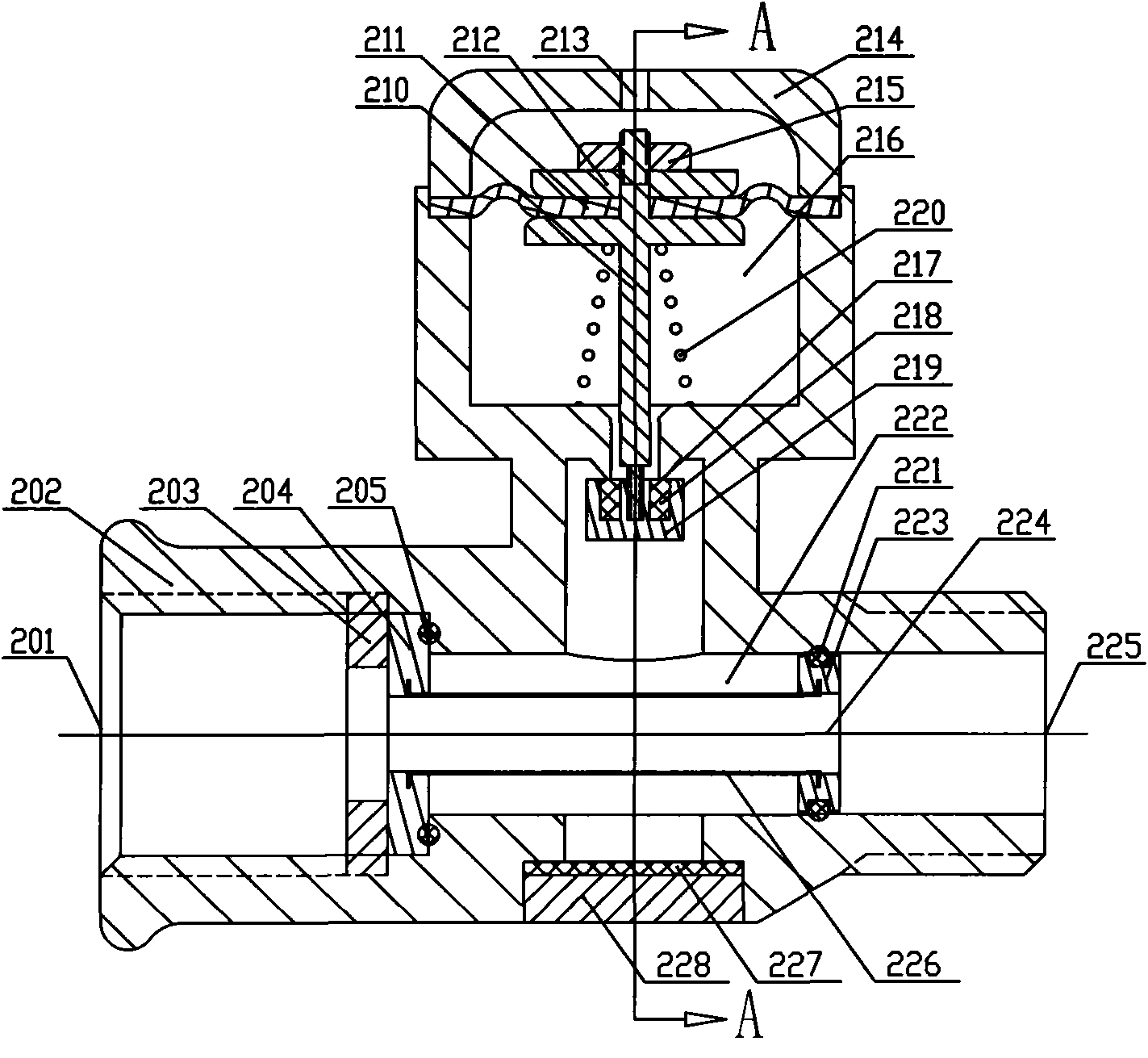

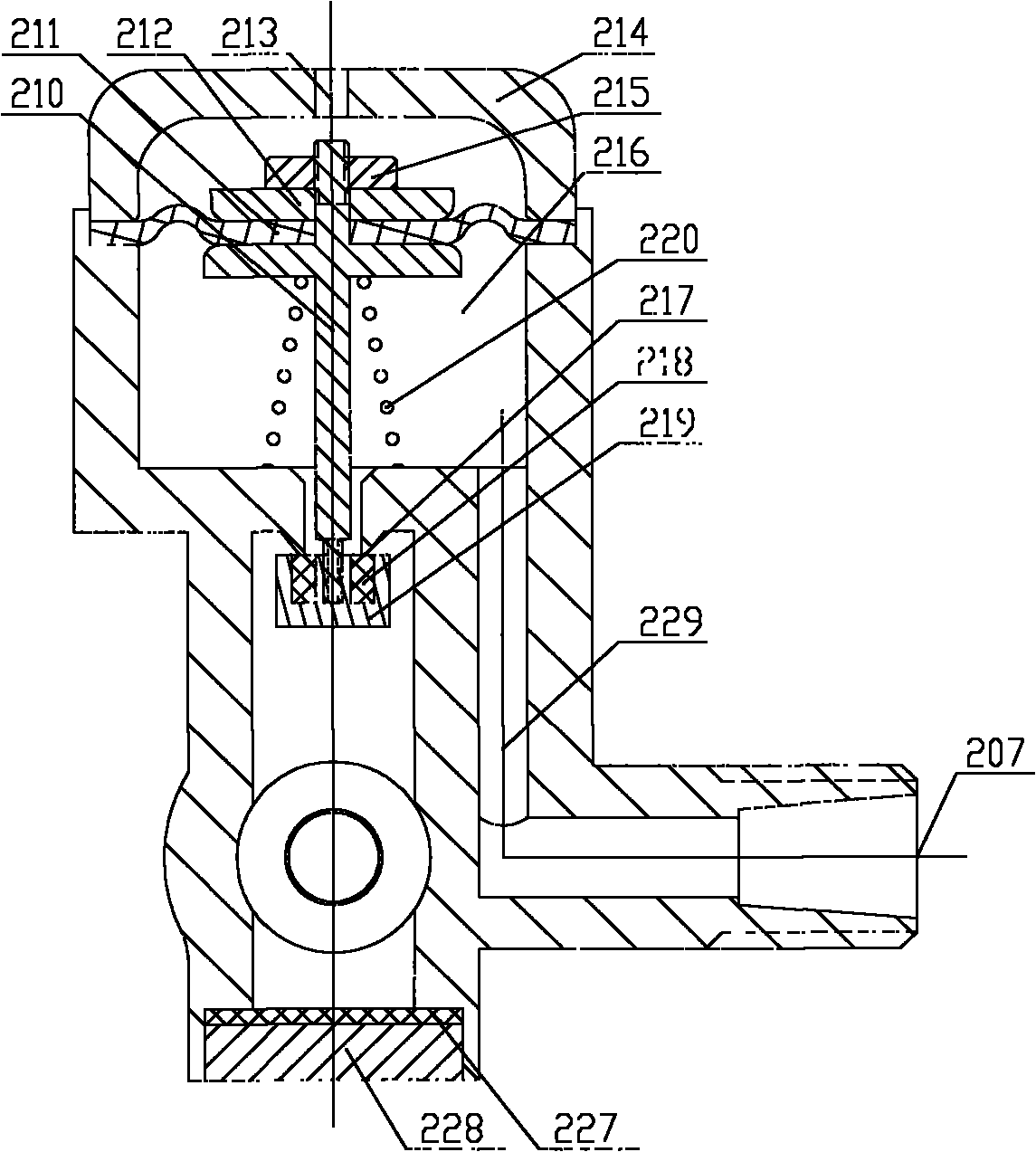

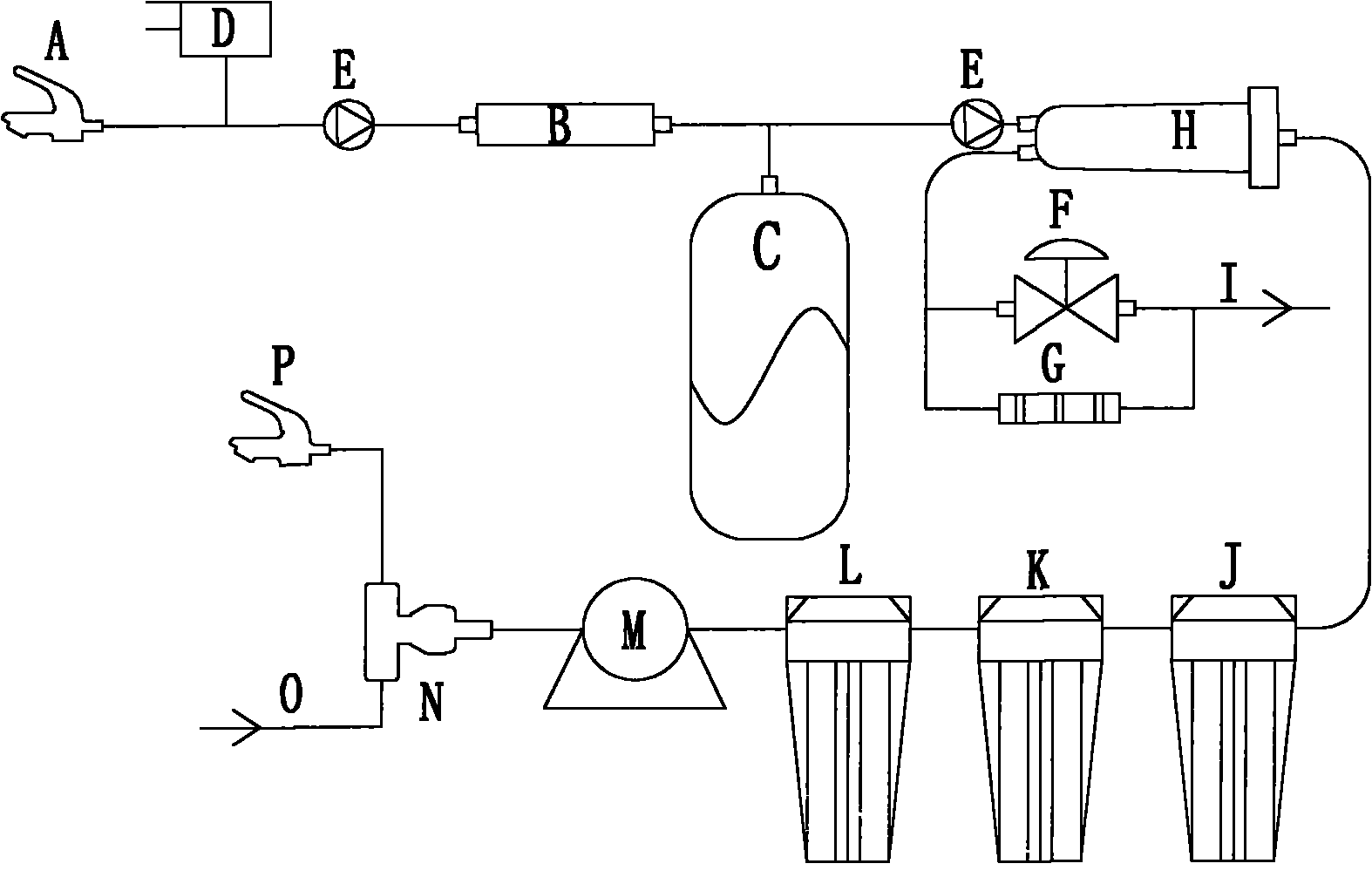

[0015] see Figure 1 to Figure 3 As shown, in the pure water machine system with the pressure limiting shut-off valve in this embodiment, the source water inlet of the pressure limiting shut-off valve is connected to the source water through the pipeline, and the source water outlet is connected to the source tap P through the pipeline, and the net The water device interface is directly connected to the water inlet of the self-priming booster pump M through the pipeline. There is no filter unit of the pure water machine before the water inlet of the self-priming booster pump M, and the water outlet of the self-priming booster pump M is connected to the PP cotton filter. The water inlet end of the barrel L is connected; the water outlet end of the PP cotton filter barrel L is connected to the water inlet end of the reverse osmosis filter barrel H through a pipeline, and the reverse osmosis filter barrel H has a clean water outlet pipeline and a concentrated water outlet pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com