Automated cleaning sheep house

A sheep house and cleaning technology, applied in the field of breeding machinery, can solve the problems of high labor cost, mass reproduction of microorganisms, untimely treatment and utilization of manure, etc., and achieve the effect of fast cleaning speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

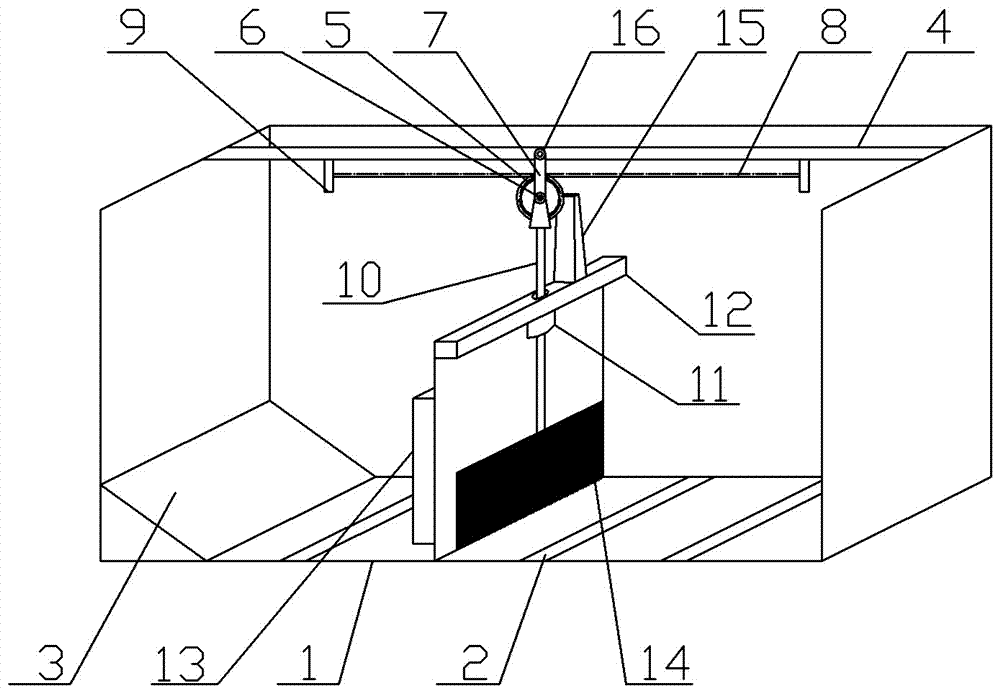

[0015] The reference signs in the accompanying drawings of the description include: bottom plate 1, drain bar hole 2, inclined plate 3, guide rail 4, driving gear 5, gear shaft 6, connecting plate 7, rack 8, limit block 9, brush handle 10, Mounting table 11, beam 12, moving plate 13, brush head 14, fixed frame 15, roller 16.

[0016] The sheep house of embodiment automatic cleaning is basically as attached figure 1 Shown: including the base plate 1, the left side, the right side and the back of the base plate 1 are surrounded by wall panels, and the front of the base plate 1 is surrounded by fence panels (the fence panels are not shown in the figure), and the top surfaces of the wall panels and fence panels are built House roof is arranged, and the plate surface of base plate 1 is separated with some excretion bar holes 2, and the bottom of base plate 1 is a septic tank....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com