Sheep house cleaning device

A cleaning device and sheep house technology, which is applied in the field of farming machinery, can solve problems such as high labor costs, damp sheep houses, and decreased air quality, and achieve the effect of fast cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

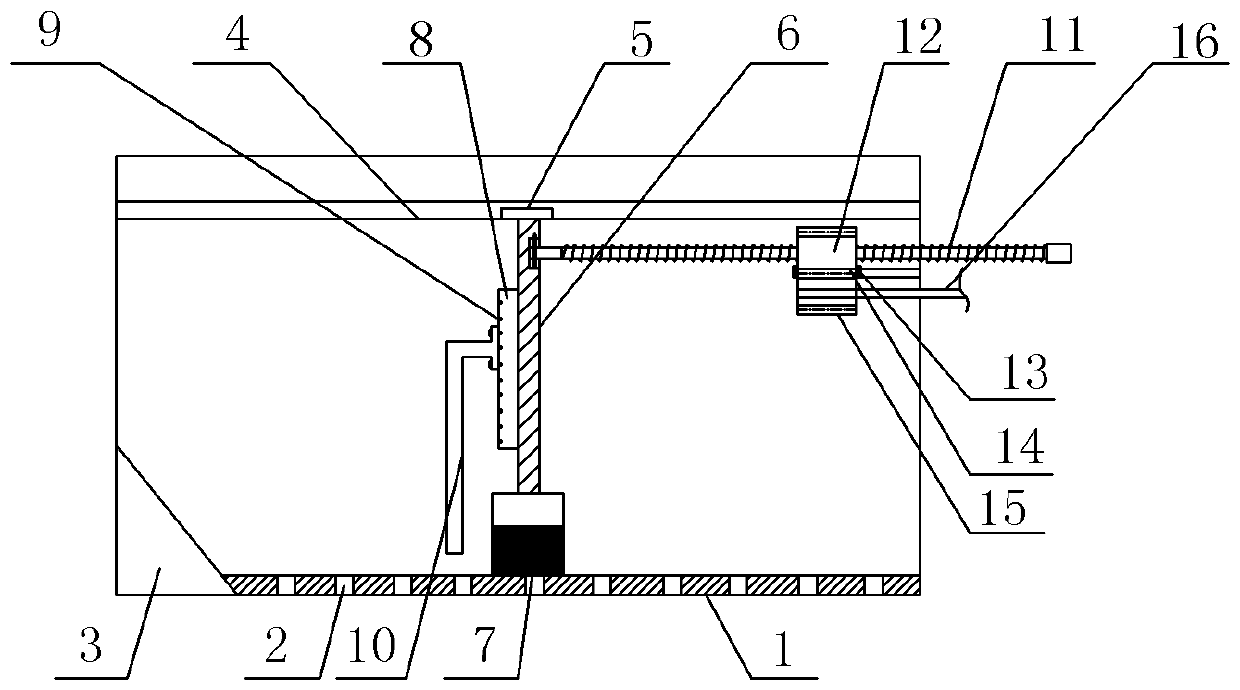

[0014] The reference signs in the accompanying drawings of the description include: bottom plate 1, excretion strip hole 2, slant plate 3, guide rail 4, slider 5, connecting rod 6, bristle brush head 7, adjustment strip 8, adjustment hole 9, driving plate 10 , screw rod 11, nut 12, claw 13, driven gear 14, driving gear 15, transmission shaft 16.

[0015] The embodiment is basically as attached figure 1 Shown: the sheep house cleaning device is installed in the sheep house, the sheep house includes a base plate 1, the left side, the right side and the back of the base plate 1 are surrounded by wall panels, and the front of the base plate 1 is surrounded by a fence board (not shown in the figure) Out of the fence board), a sheep shed roof is built on the top surface of the wall board and the fence board, a number of excretion holes 2 are spaced apart on the board surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com