A feeding pan for poultry

A feeding pan and feeding pan technology, applied in the application, poultry industry, animal husbandry and other directions, can solve the problems of easy drilling into the feeding pan, unreachable chicks, affecting the growth of chickens, etc., to ensure cleanliness and avoid waste. , The effect of preventing chickens from being cooked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

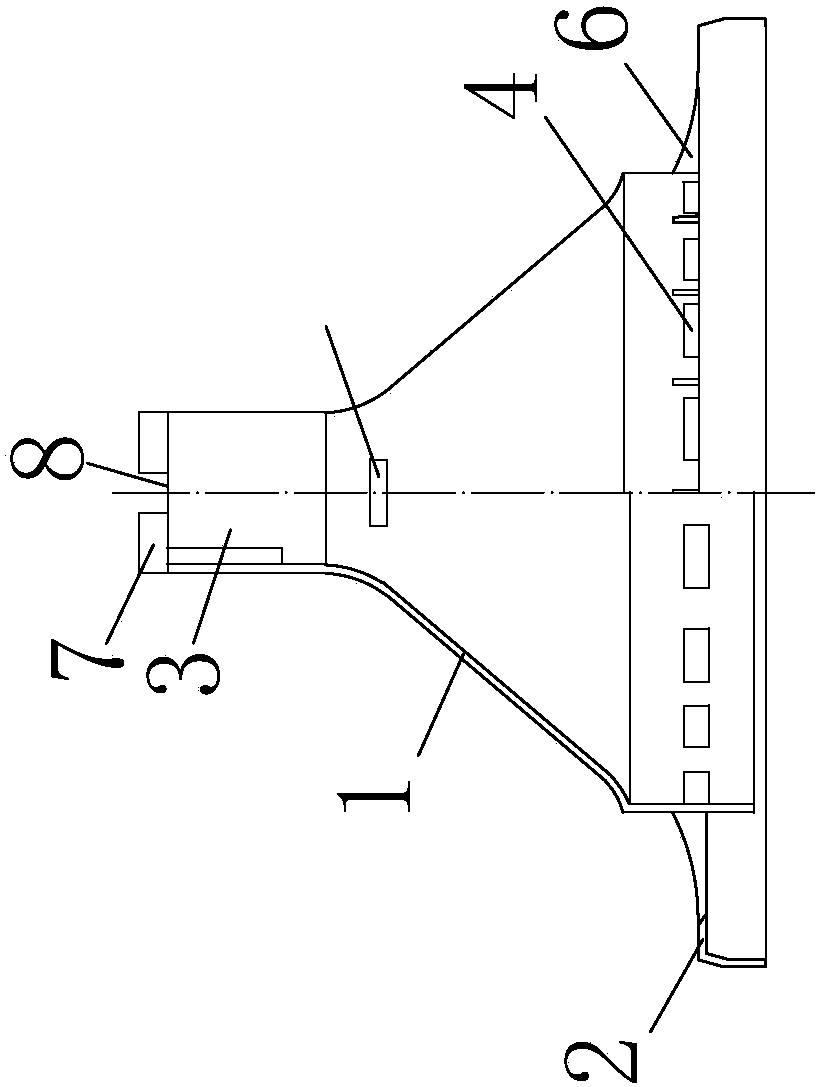

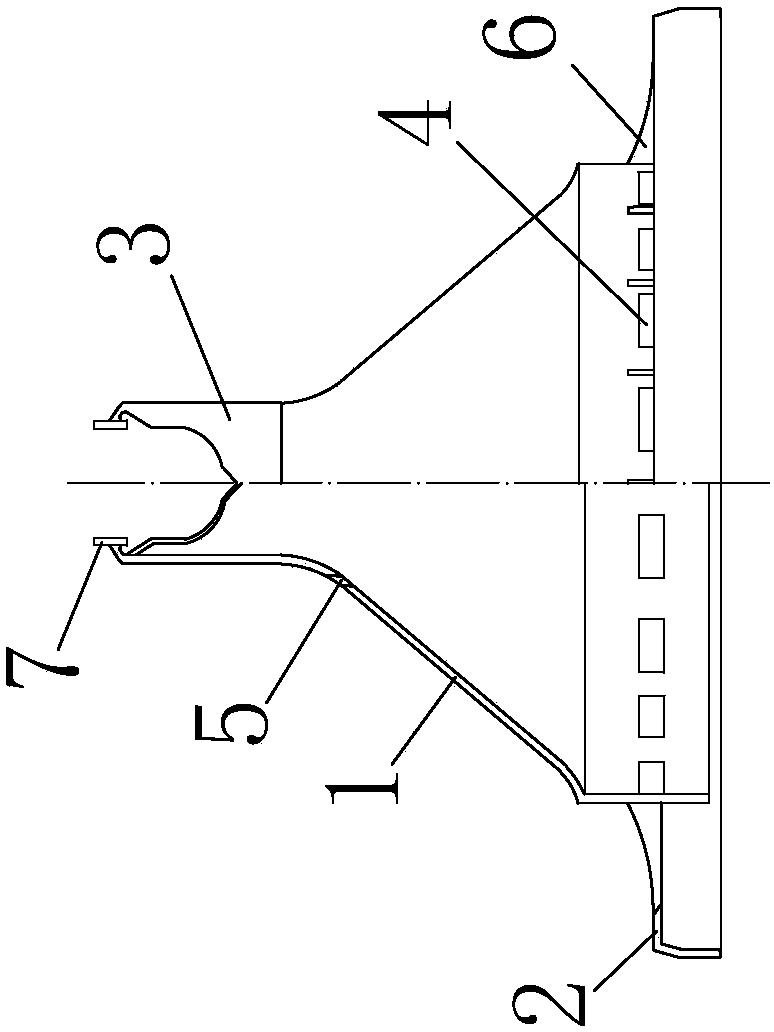

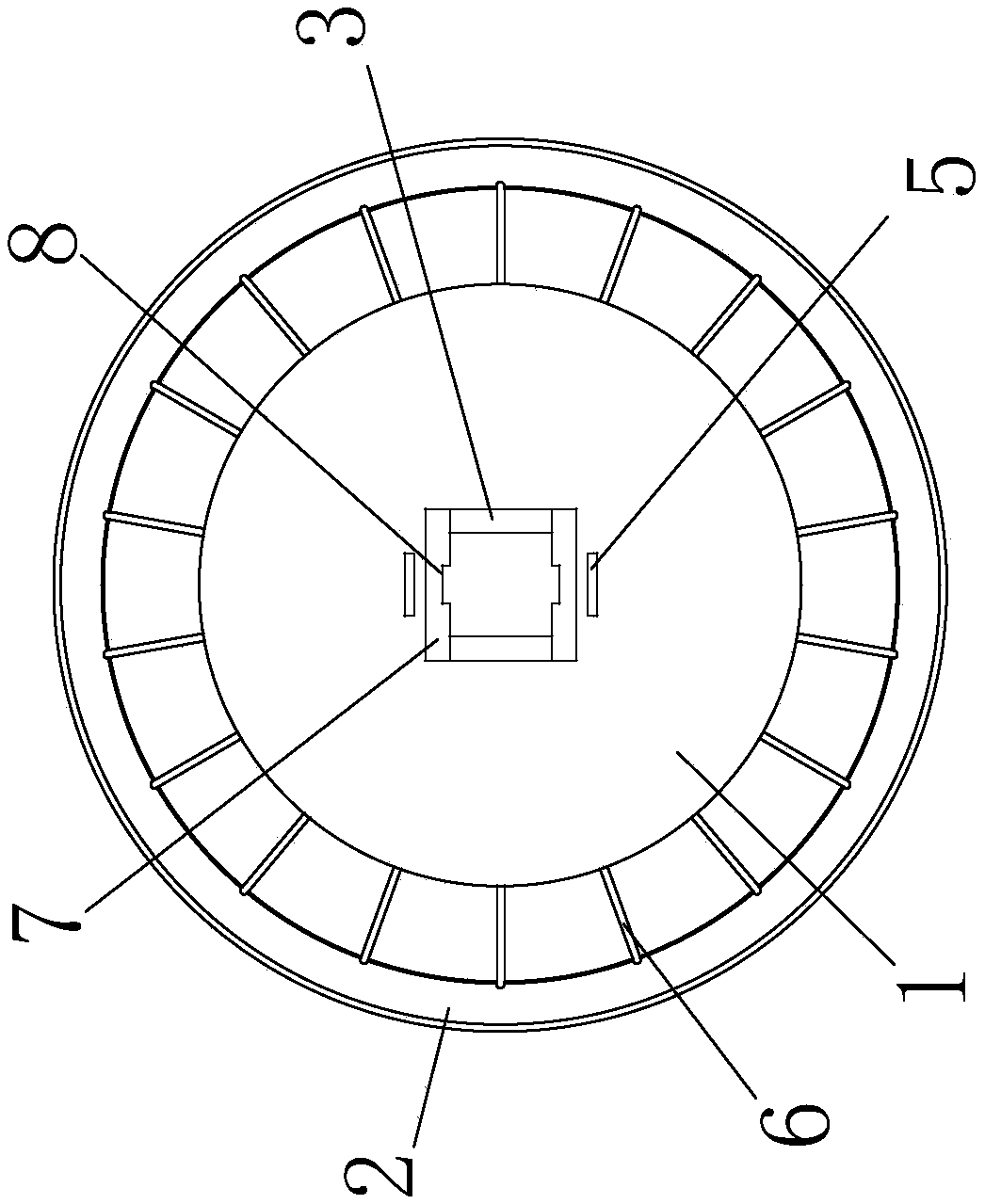

[0029] Such as Figure 1-12 As shown, a feeding pan for poultry includes an outer pan body and an inner pan body. Conical, and a tray fixing seat 3 is provided on its top, a circle of small discharge openings 4 is provided at the bottom of the outer tray shell 1, and lower tray fixing holes 5 are respectively provided on both sides of the top of the outer tray shell 1, The annular buckle plate 2 is set on the bottom of the outer tray housing 1, and is connected with the outer tray housing 1 through a plurality of evenly arranged partition plates 6. The top of the tray fixing seat 3 is provided with a symmetrical slide plate 7, each The middle part of slide plate 7 is respectively provided with breach 8, and inner disc body is made up of tapered material guide housing 9 and annular material tray 10, and the both sides of material guide housing 9 tops are respectively provided with lower housing fixed plate 11, each The top of the lower shell fixed inserting plate 11 is respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com