Use method for welding clamp for gas-liquid separator

A gas-liquid separator and welding fixture technology, applied in the field of tooling fixtures, can solve the problems of weak air tightness, poor, and hindering the wide production and use of gas-liquid separators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

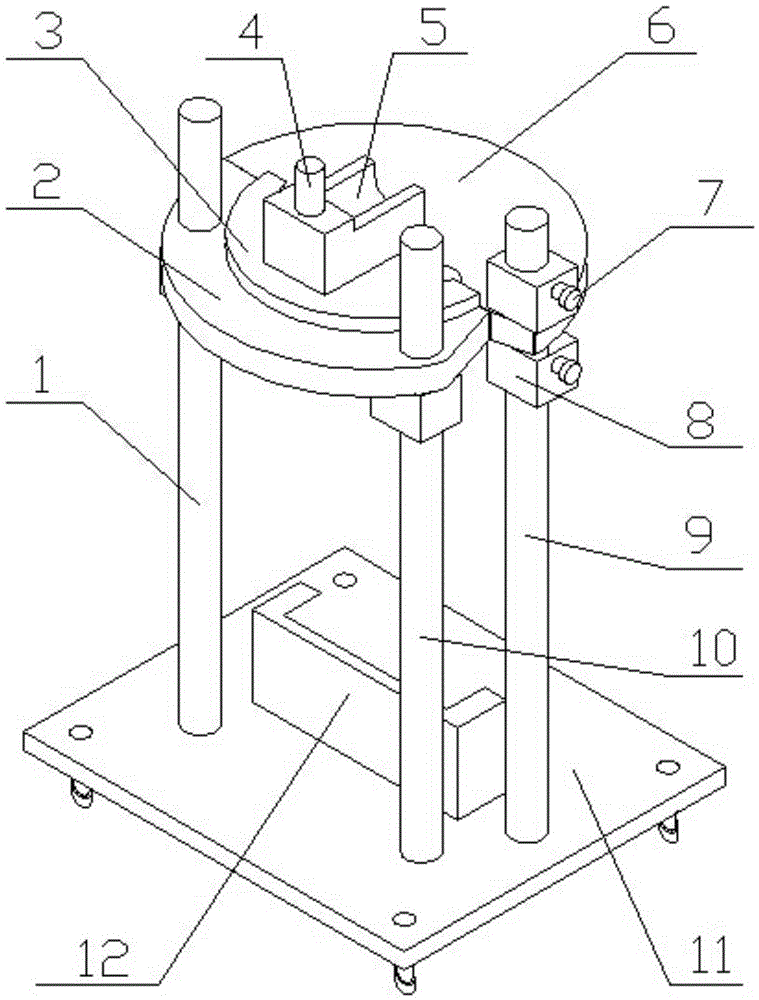

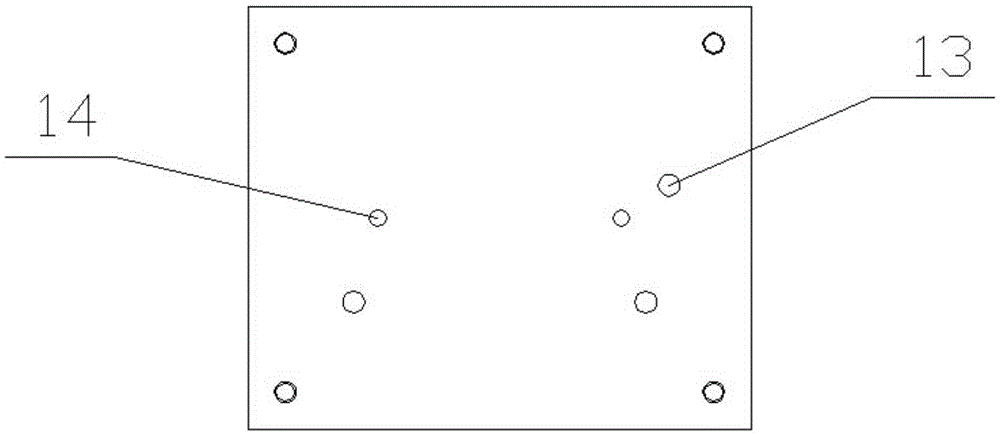

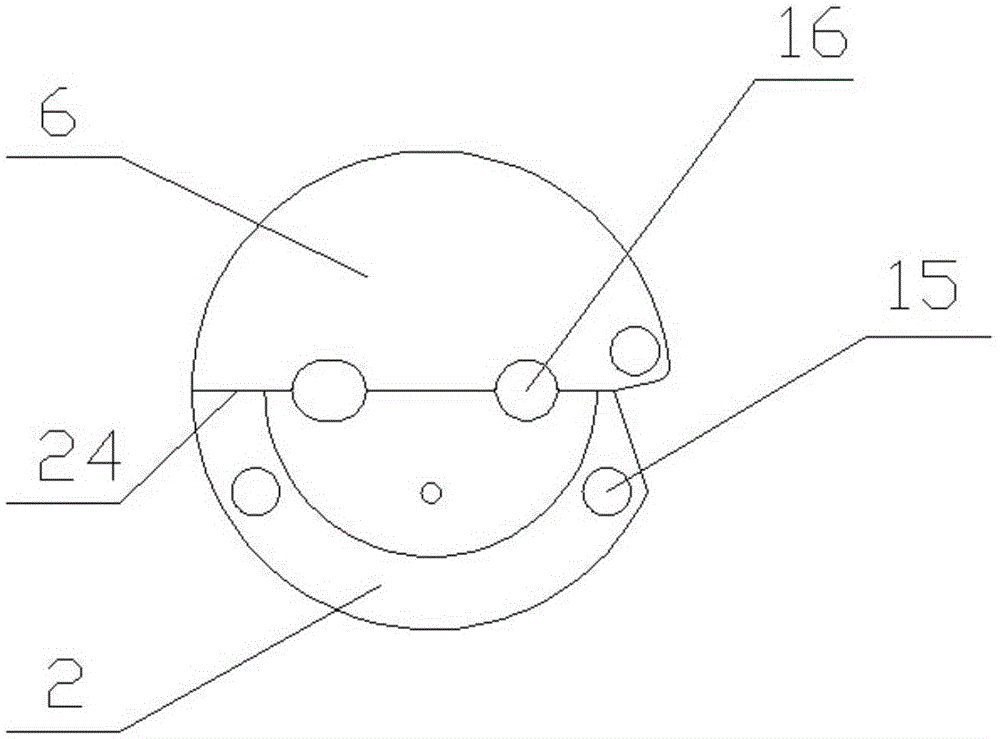

[0053] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, a gas-liquid separator welding fixture, which includes a first guide post 1, a semi-circular support block 2, a guide post 4, an intake pipe support block 5, a rotating semi-circular support block 6, a positioning block 8, and a second guide post 9 , the third guide post 10, the base 11 and the limit backing plate 12; the base 11 is provided with two limit backing plate mounting holes 14 and three guide post mounting holes 13; the axes of the three guide post mounting holes 13 and the base The connection line of the three intersection points on the upper surface of 11 forms a right triangle; the axis of the two limit back plate installation holes 14 and the connection line of the two intersection points on the upper surface of the base 11 are parallel to the connection line of the three...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap