A floating press-fit turbine shell bushing device and its alignment and positioning method

A turbine shell and bushing technology, applied in the field of fixtures, can solve the problems of extrusion deformation of parts bushing holes, complicated operation, low positioning accuracy, etc., to ensure the qualified rate of press-fitting, easy and reliable operation, and improve press-fitting accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, this frock technical scheme is further described:

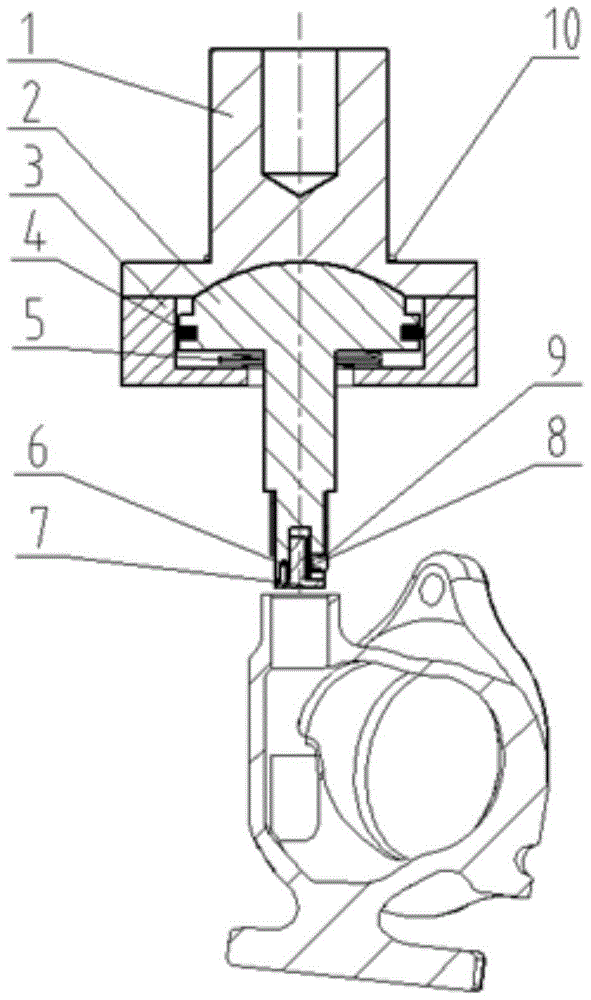

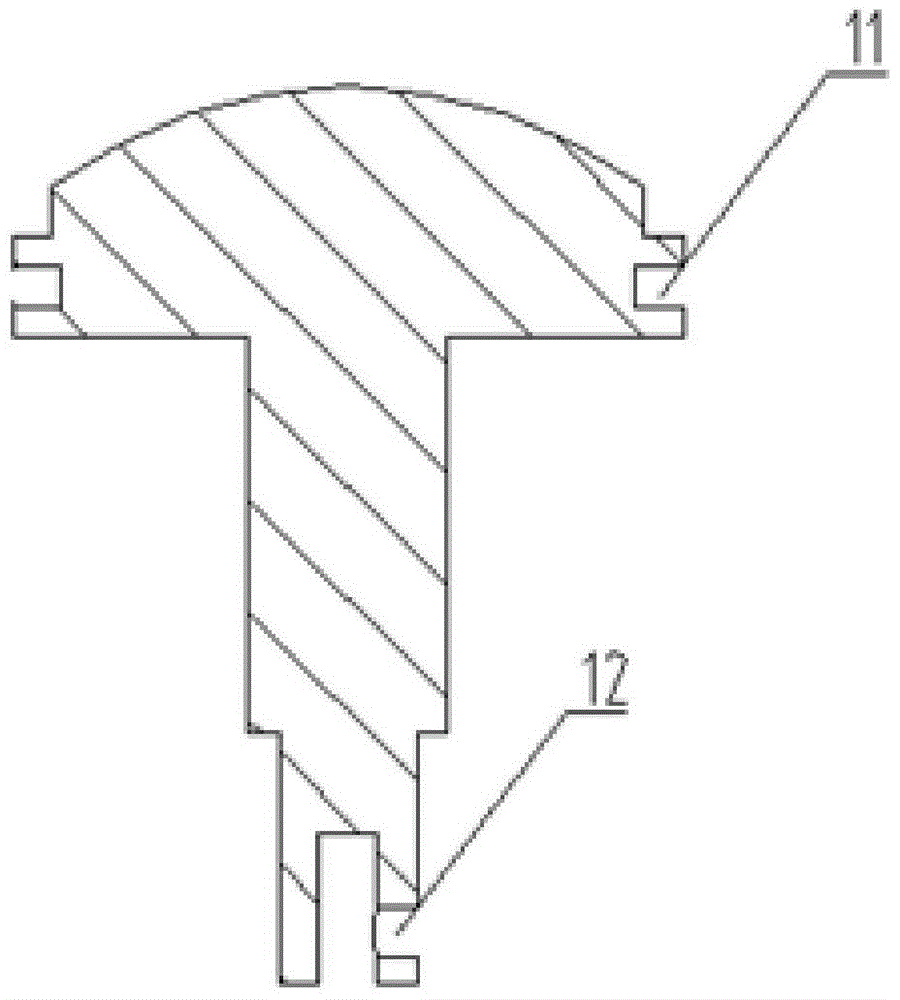

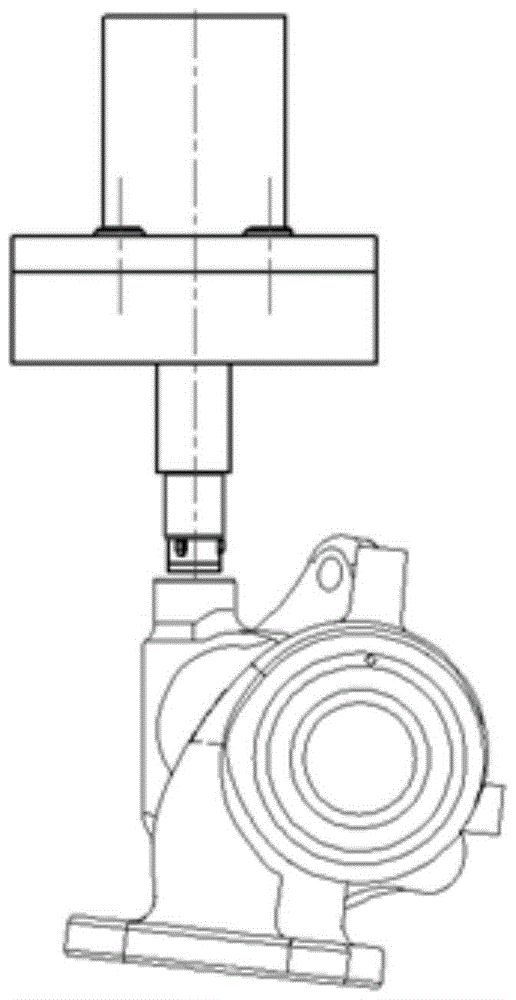

[0015] Such as Figure 1-7 As shown, the device includes a connecting base 1 directly bolted to the press, which has a spherical structure; the positioning rod 2 with a groove structure is opened on the lower part of the spherical structure of the connecting base, and the groove structure is used to accommodate the fastening rod 7 And the guide block 9, wherein the cylindrical perforation 12 is used to install the alignment spring 8 and the guide block 9, the guide block 9 is covered with the alignment spring 8; the guiding function of the guide block 9 is guaranteed; it is connected to the connection base 1 through the fixing bolt 10 The fixed block 3 is mainly used to fix the small spring 4 and the large spring 5, and to make the spring have a certain pressing force; the small spring groove 11 embedded in the positioning rod 2 is used to install the small spring 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com