Jointing pant of automobile drive system

A technology for connecting parts and transmission systems, applied in the field of connecting parts, to achieve the effect of increasing service life, reducing diameter and thickness, and widening the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

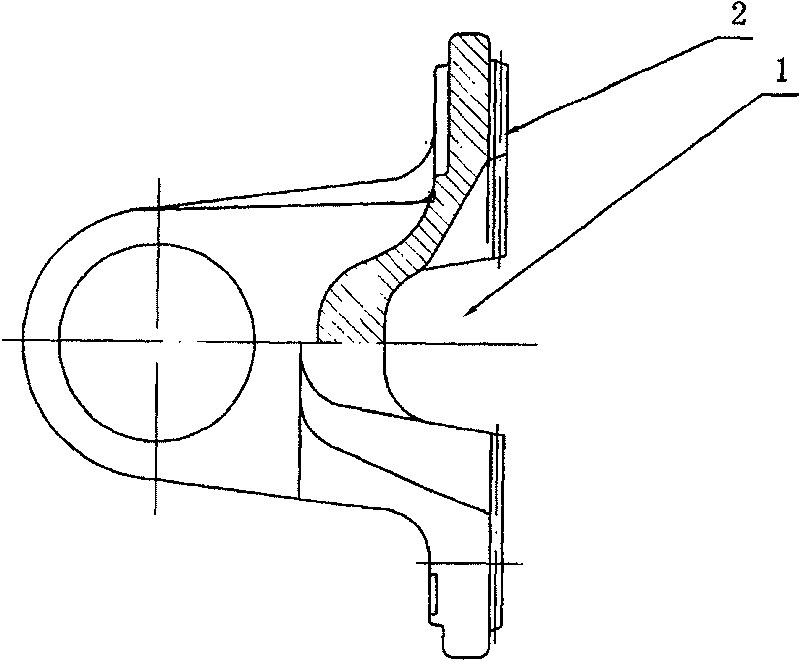

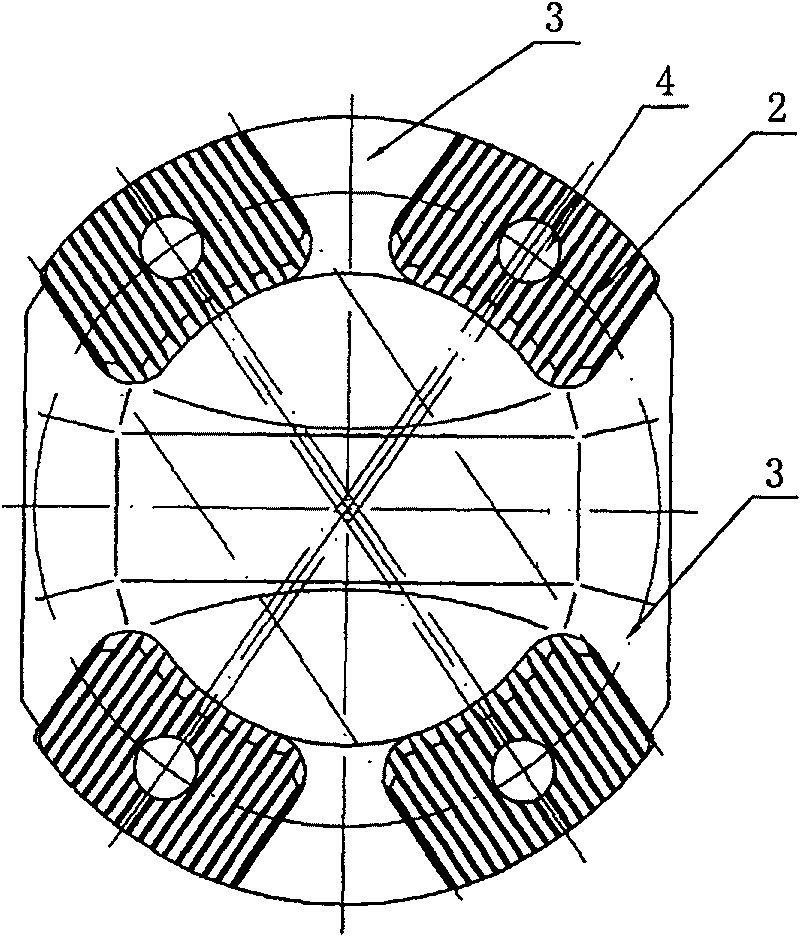

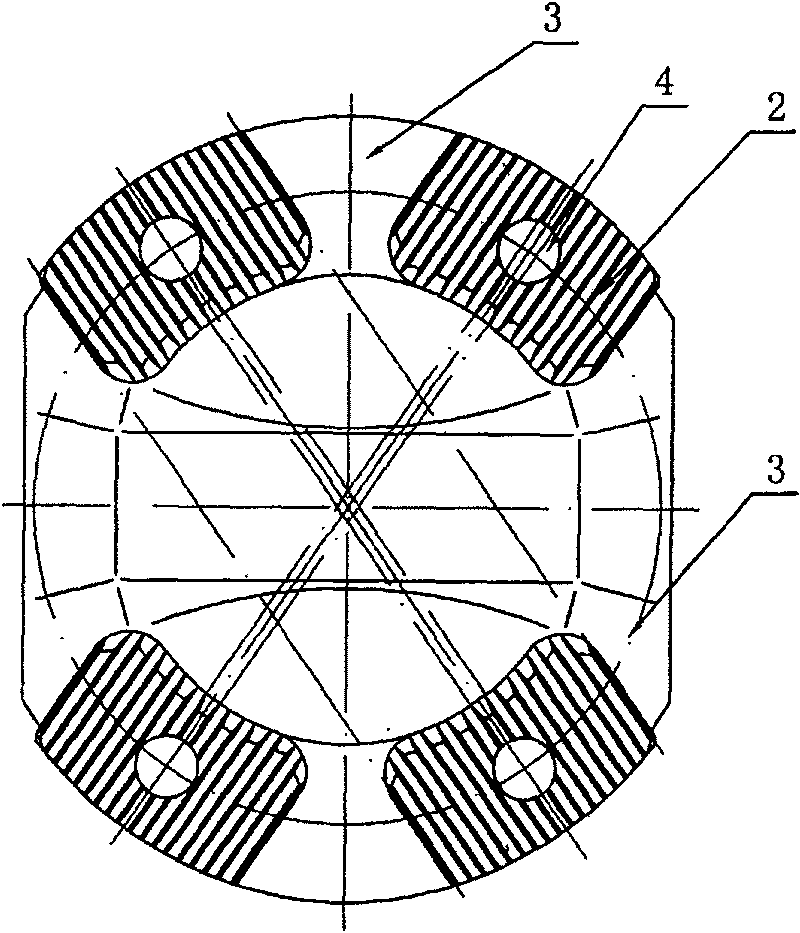

[0009] Such as figure 1 , 2 The structure of the connecting part of the end face of the connecting parts of the automobile transmission system shown is: the central part 1 of the end face is recessed, two sets of end face teeth 2 distributed at a certain angle are arranged on the end face circumference, and the end face circumference parts avoiding the end face teeth 2 are set. There is a sunken weight-reducing groove 3; a connecting hole 4 is also provided on the circumference of the end face.

[0010] The angle between the two groups of face teeth is generally between 60° and 80°, and the number of teeth in each group of face teeth is 6 to 10. The tooth shape of the end tooth is generally rectangular or involute or trapezoidal, and it is most convenient to process with rectangular teeth.

[0011] Combined with the structure and space arrangement of the connecting parts of the current automobile transmission system, the angle between the two sets of end face teeth is prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com