Method for automatically detecting air valve friction welding yield strength

An automatic detection and yield strength technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, conveyor objects, transportation and packaging, etc., can solve the problems of high labor costs, chaotic management, operational errors, etc., and achieve work efficiency The effect of high height, large clamping range and simplified test device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

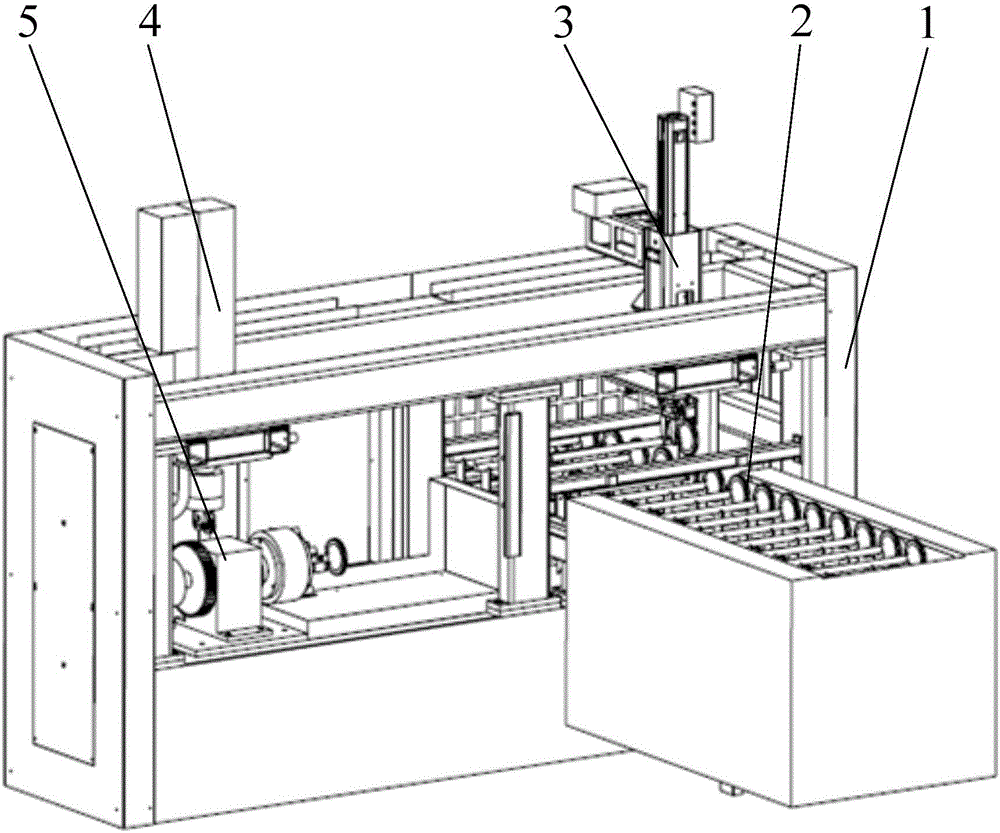

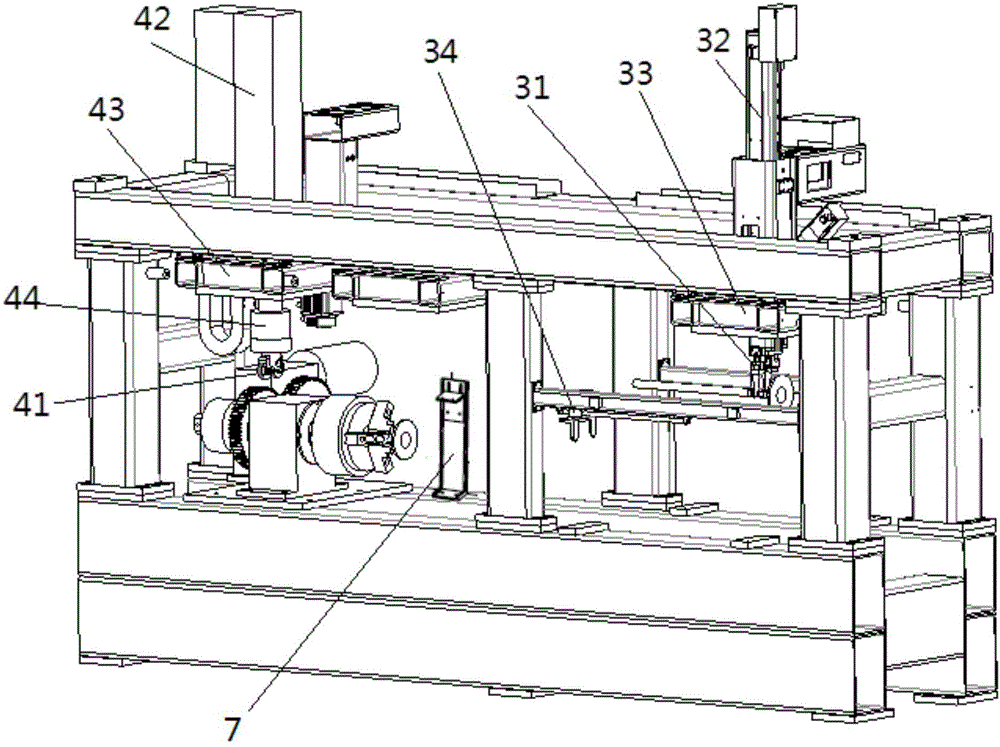

[0037] see Figure 1 to Figure 7 , this embodiment discloses a method for automatic detection of the friction welding yield strength of a valve. The valve is welded by a head and a rod. The method is based on a detection device. There are automatic loading and unloading conveying mechanism 2, loading and unloading manipulator module 3, electric cylinder loading module 4, hydraulic chuck clamping mechanism 5,

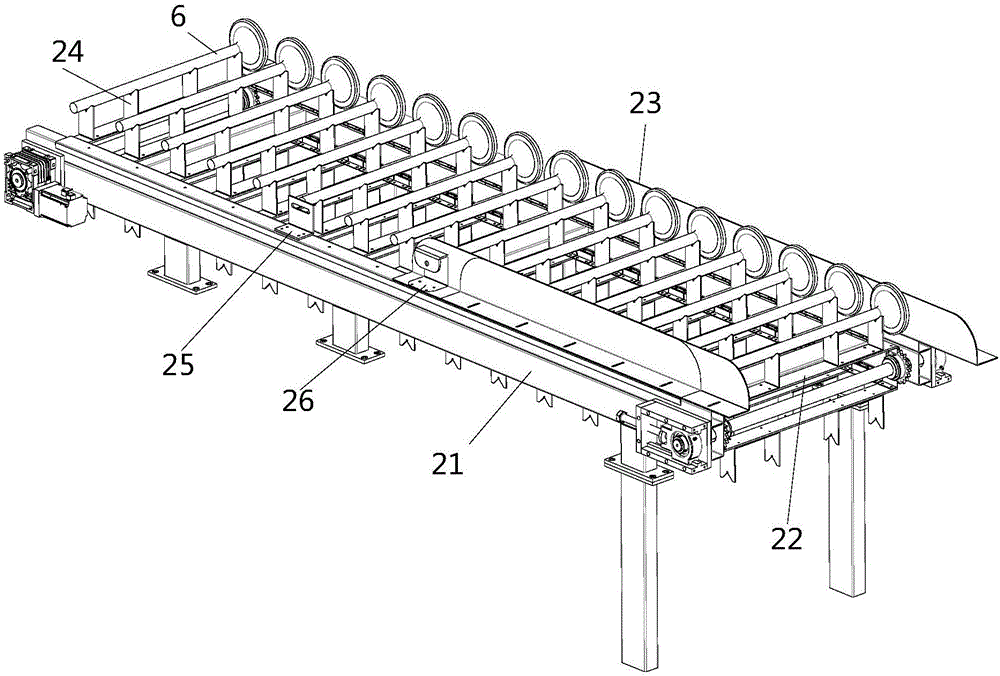

[0038] The automatic loading and unloading conveying mechanism 2 includes a support 21, a conveying chain plate 22 arranged on the support 21, a plurality of support block groups, two photoelectric switches, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com