Glass ribbon transporting device, glass plate manufacturing device and glass plate manufacturing method

A technology for handling devices and manufacturing devices, which can be used in glass manufacturing equipment, glass transportation equipment, glass production, etc., and can solve problems such as defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, modes for implementing the present invention will be described with reference to the drawings, but the present invention is not limited to the embodiments described below, and various modifications and substitutions can be added to the following embodiments without departing from the scope of the present invention.

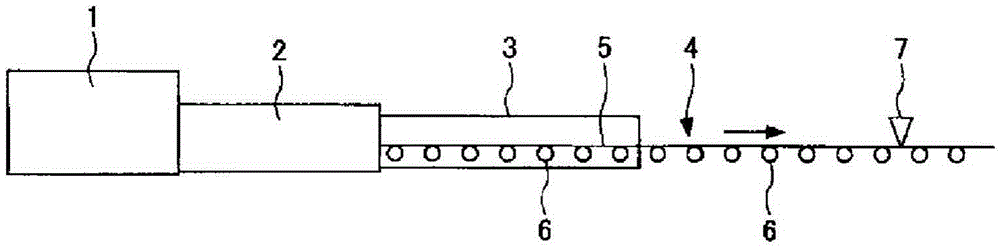

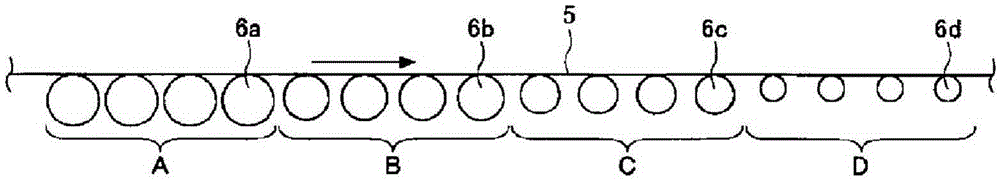

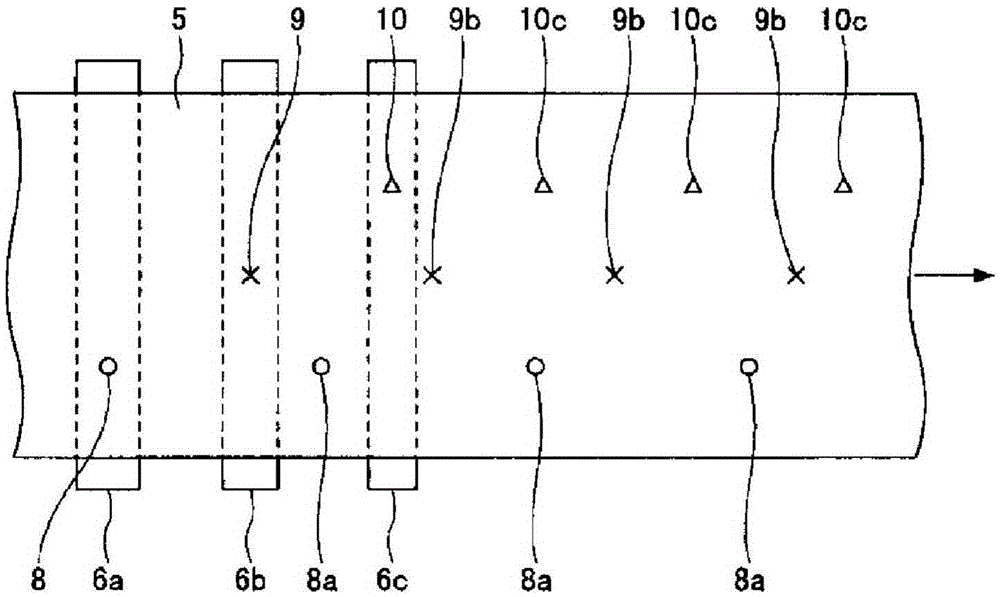

[0045] figure 1 It is a side view of the glass plate manufacturing apparatus provided with the glass ribbon conveyance apparatus which concerns on one Embodiment of this invention. In this float glass manufacturing apparatus, the molten glass obtained in the glass melting furnace 1 is supplied onto the molten tin in the molten metal tank 2 to form a glass ribbon 5 in a ribbon shape. After the formed glass ribbon 5 is lifted from the molten metal tank 2 by lifting rollers and taken out, it is transported by the glass ribbon conveying device and slowly cooled to below the strain point temperature of the glass in the slow cooling furnace 3, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap