Thread trimming mechanism driving device for sewing machine

A thread-cutting mechanism and a driving device technology are applied to the thread-cutting mechanism, sewing machine components, sewing equipment and other directions in a sewing machine, which can solve the problems of high precision requirements of electromagnets, failure of the thread-cutting function of the sewing machine to work normally, stuck and other problems. To solve the effect of unstable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

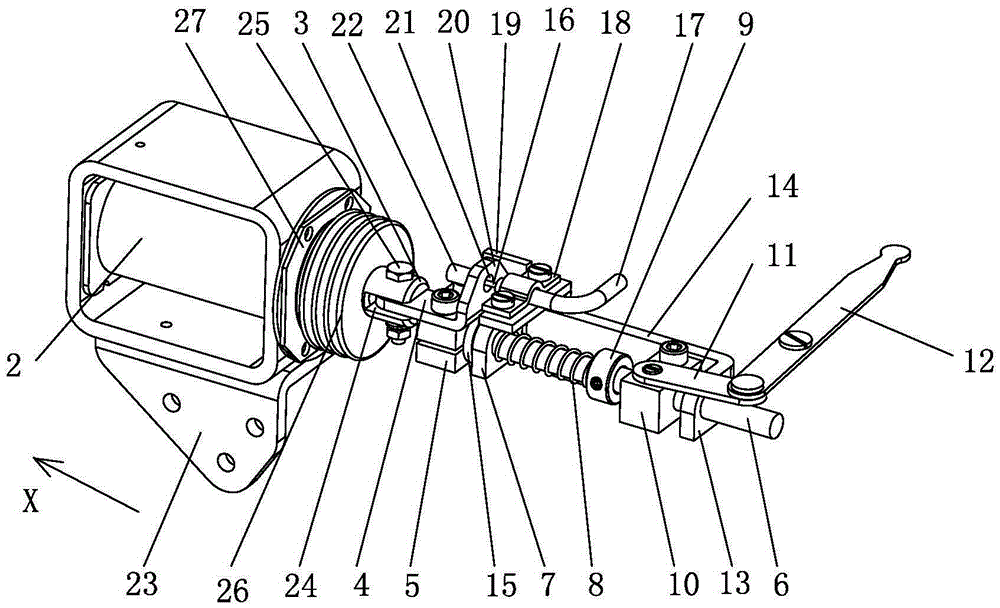

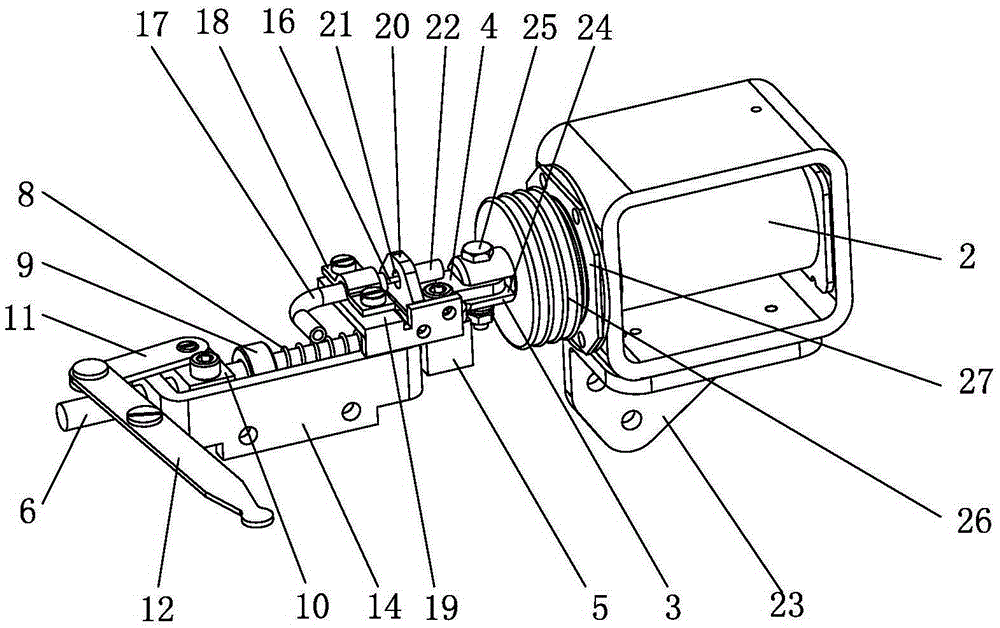

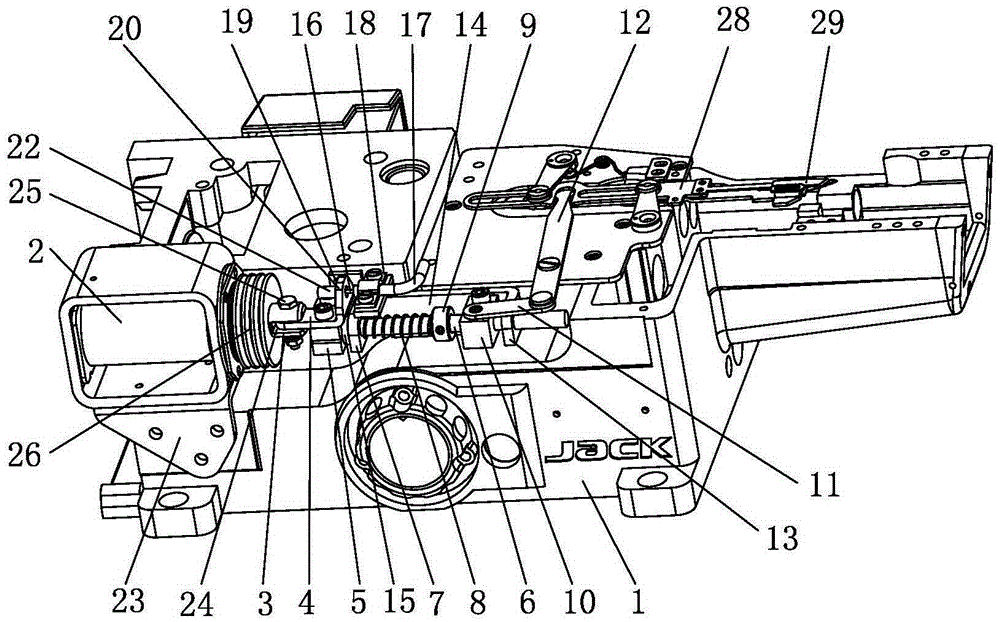

[0021] The present invention will be further described below with specific embodiment, see figure 1 —4:

[0022] A sewing machine thread trimming mechanism drive device, including a driver 2 fixed on the casing 1, the movable rod 3 of the driver 2 is connected with a connecting plate 4, the connecting plate 4 is connected with a guide rod 6 through a crank block 5, and the guide rod 6 There is a spring seat 7 fixed on the casing 1, the return spring 8 is set outside the guide rod 6, and one end of the return spring 8 is pressed against the spring seat 7, and the other end is pressed against the retaining ring 9, and the retaining ring 9 is fixed on the guide bar 6, adjust the position of the retaining ring 9 on the guide bar 6 and then adjust the elastic force of the return spring 8, the guide bar 6 is also provided with a guide block 10, the guide block 10 is connected with the knife through the thread trimmer connecting rod 11 The disc drive rod 12 is connected, and the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com