Bridge prefabricated pier column and cap socket socket connection structure and its assembly method

A connection structure, socket-type technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of large workload, low redundancy of on-site construction adjustment, high construction positioning accuracy requirements, etc., and meet the positioning accuracy requirements. Low, low manufacturing and processing requirements, fast and convenient on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

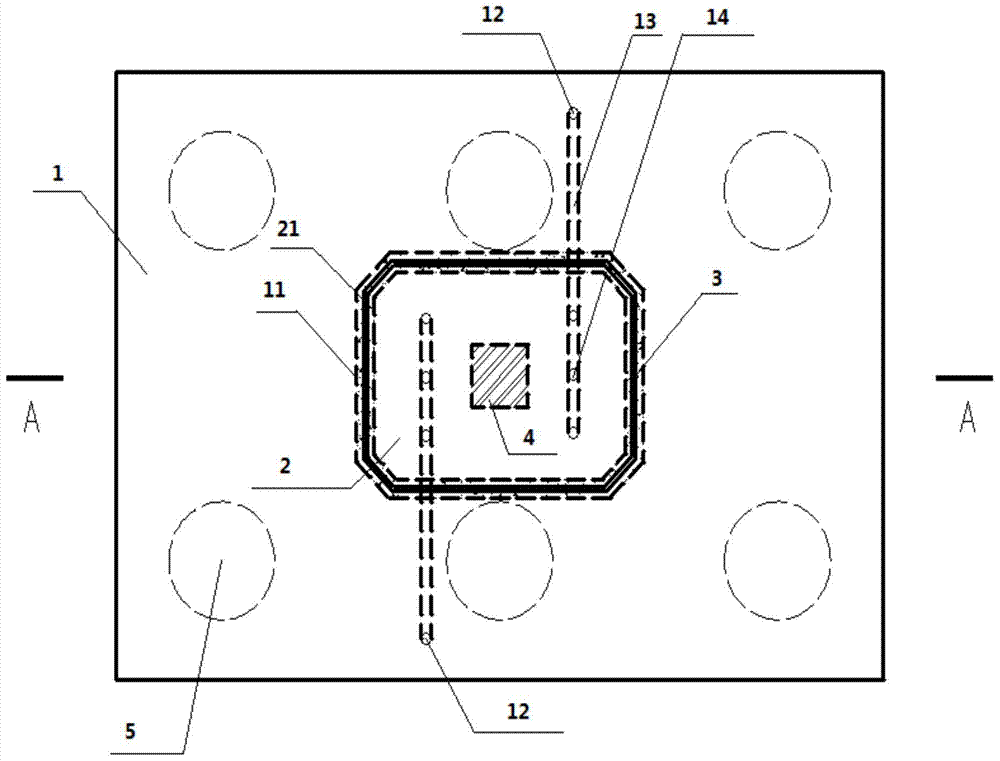

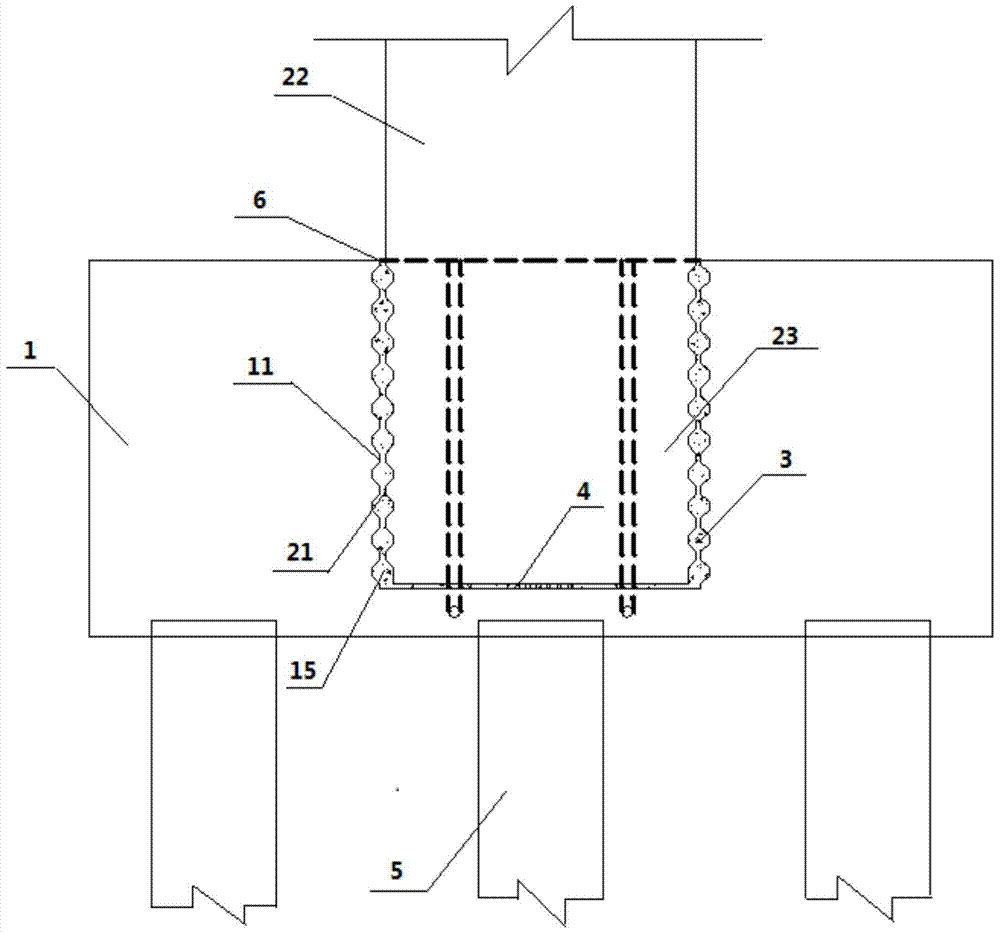

[0029] Such as figure 1 image 3 As shown, a specific embodiment of a bridge prefabricated pier column and cap socket type connection structure and an assembly method thereof of the present invention includes the following steps:

[0030] The prefabricated column 2 includes an exposed end 22 and an embedded end 23. The embedded end 23 is used to be embedded in the cap 1. Those skilled in the art should know that the cross-sectional size and reinforcement of the column embedded end 23 must meet the requirements of the bridge structure for normal use and Various technical requirements for keeping the bridge strong under the action of earthquakes. In this embodiment, the outer contour size of the exposed end 22 of the column is equal to the maximum outer contour size of the embedded end 23, and the outer wall of the embedded end 23 of the column is provided with several annular raised column shear force key 21.

[0031] The prefabricated platform 1 is provided with a column ins...

Embodiment 2

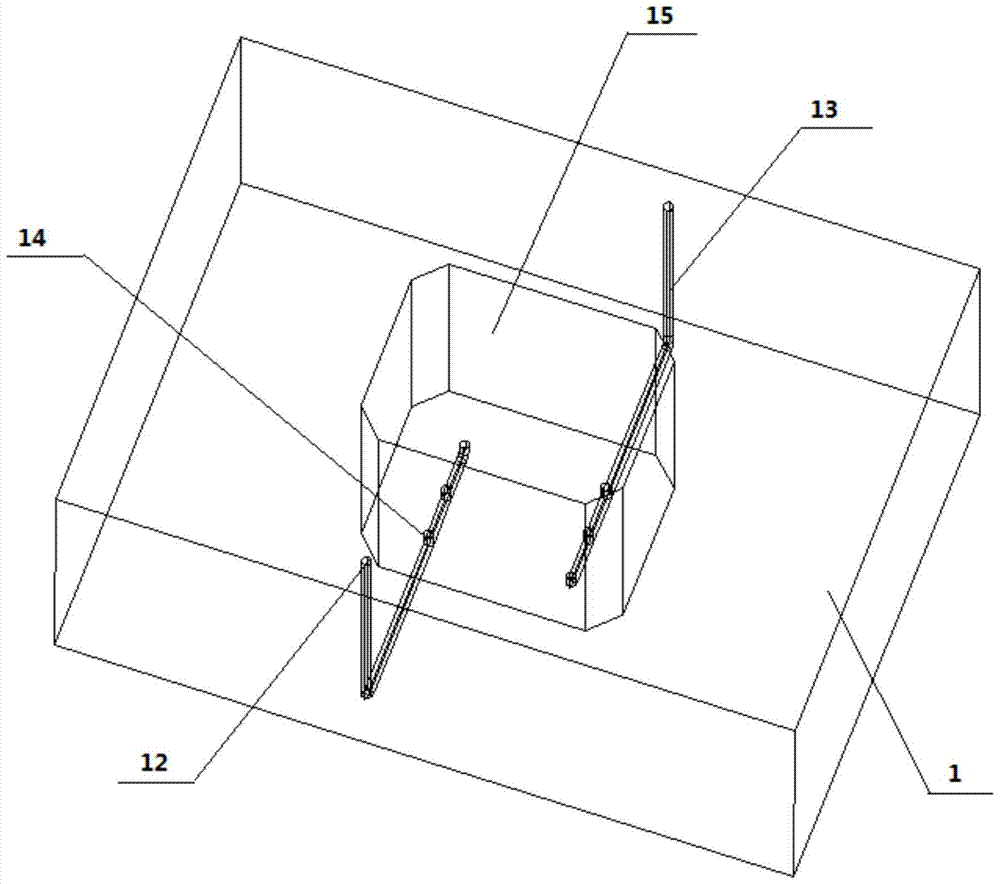

[0036] Such as Figure 4-6 As shown, another specific embodiment of a bridge prefabricated pier column and cap socket socket connection structure and its assembly method of the present invention includes the following steps:

[0037] The prefabricated column 2, the column 2 includes an exposed end 22 and an embedded end 23, the embedded end 23 is used to be embedded in the cap 1, those skilled in the art should know that the cross-section size and reinforcement of the column embedded end 23 must meet the normal use of the structure and the earthquake According to various technical requirements, in this embodiment, the outer contour size of the exposed end 22 of the column is larger than the maximum outer contour size of the embedded end 23, and the outer wall of the embedded end 23 of the column is provided with several annular raised column shear keys 21.

[0038] The cast-in-place cap 1 is provided with a column installation hole 15 in the vertical direction of the cap 1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com