Prefabricated pier upright column, cushion cap spigot and insertion groove combined connection structure and splicing method

A combined connection and column technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problem of large amount of bearing material, achieve the effect of low manufacturing and processing requirements, avoid the thickness of the bearing platform, and fast and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

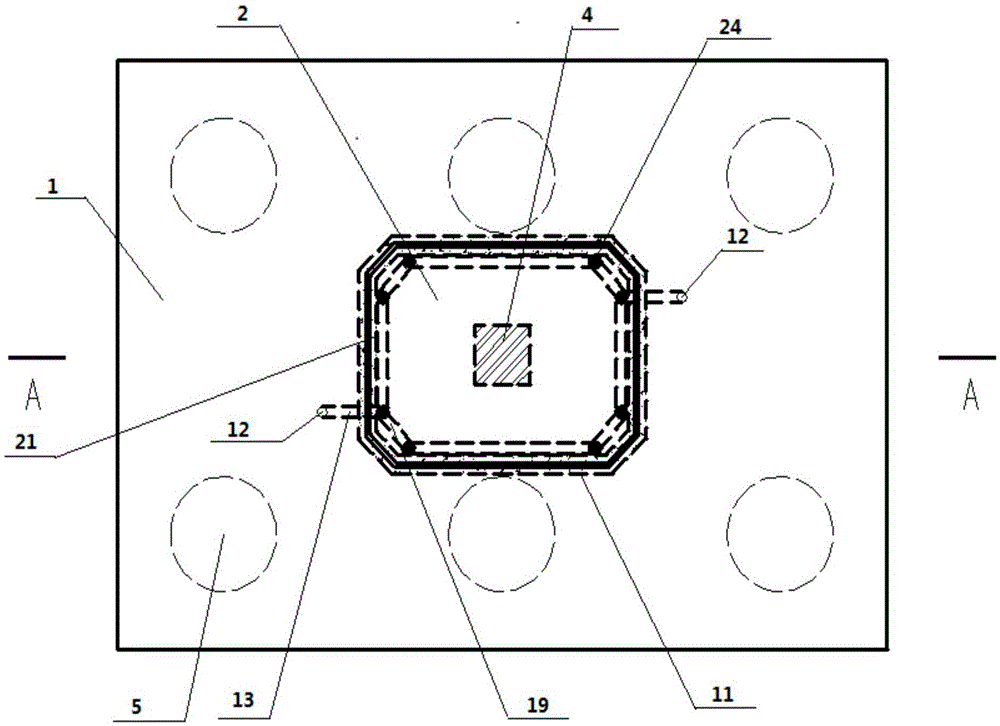

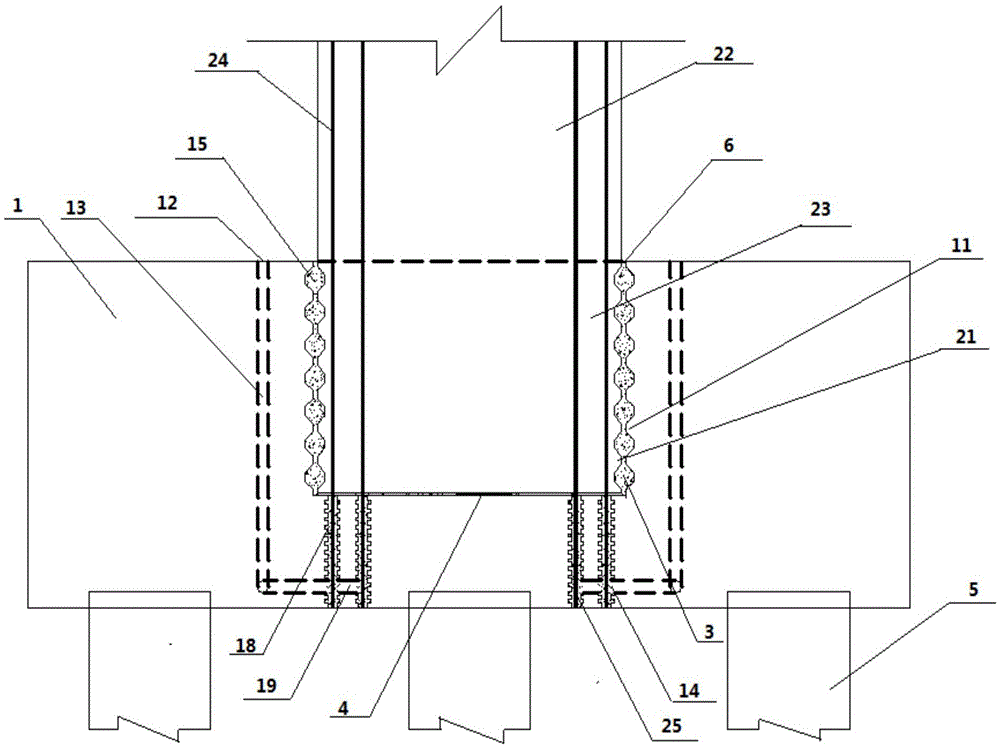

[0029] like Figure 1-Figure 2 As shown, a specific embodiment of the combined connection structure and assembly method of the prefabricated bridge pier column and the cap socket and the socket of the present invention includes the following steps:

[0030] Prefabricated column 2, prefabricated column 2 includes column exposed end 22 and column embedded end 23, several steel bars 24 are embedded in prefabricated column 2, and steel bar 24 is provided with the free end 25 that stretches out certain length from the bottom end of column embedded end 23; The skilled person should know that the cross-section size and reinforcement of the column embedded end 23, as well as the number of steel bars provided and the length of the free end of the steel bars need to meet the various technical requirements for the normal use of the bridge structure and for the bridge to remain firm under earthquake action. In this embodiment The outer contour dimension of the exposed end 22 of the column...

Embodiment 2

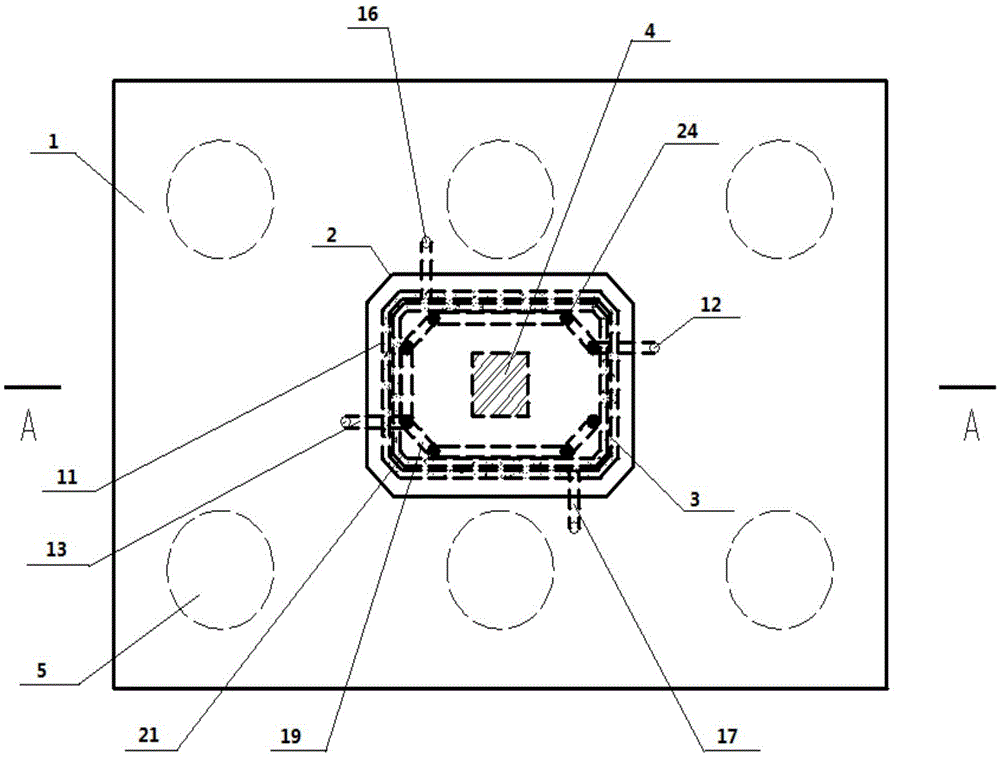

[0037] like Figure 3-Figure 4 As shown, another specific embodiment of the combined connection structure and assembly method of the prefabricated bridge pier column and the cap socket and the socket of the present invention includes the following steps:

[0038] Prefabricated column 2, column 2 comprises exposed end 22 and embedded end 23, and several steel bars 24 are embedded in column 2, and steel bar 24 is provided with the free end 25 that stretches out certain length from the bottom end of column embedded end 23; Those skilled in the art should know , the cross-sectional size and reinforcement of the column embedded end 23, the number of steel bars set and the length of the free end of the steel bar need to meet the various technical requirements for the normal use of the bridge structure and the bridge's firmness under earthquake action. In this embodiment, the exposed end 22 of the column The outer contour size is greater than the maximum outer contour size of the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com