Composite floor with self-weight reducing function and favorable structural stiffness

A technology for structural rigidity and self-weight reduction, applied to floors, building components, building structures, etc., can solve problems such as mold floating and upper and lower plate thicknesses, achieve good load-bearing effect, reduce floor self-weight, and improve overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

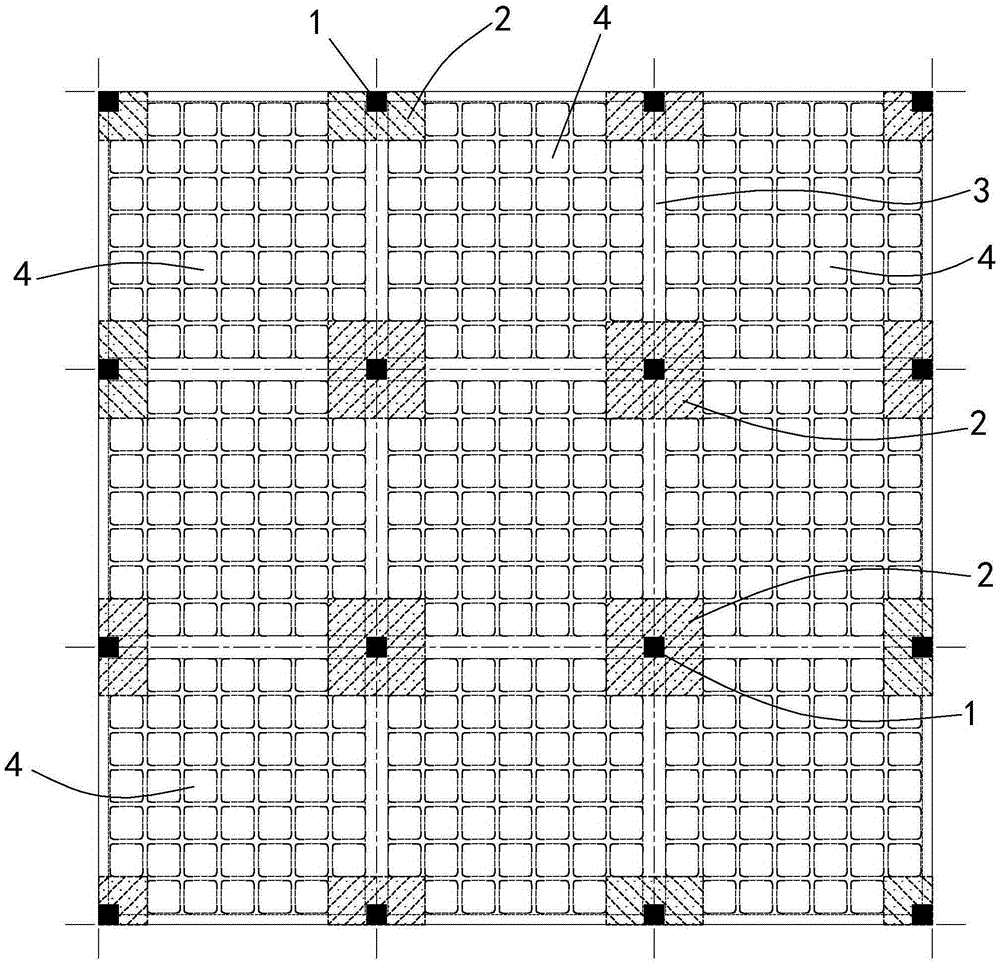

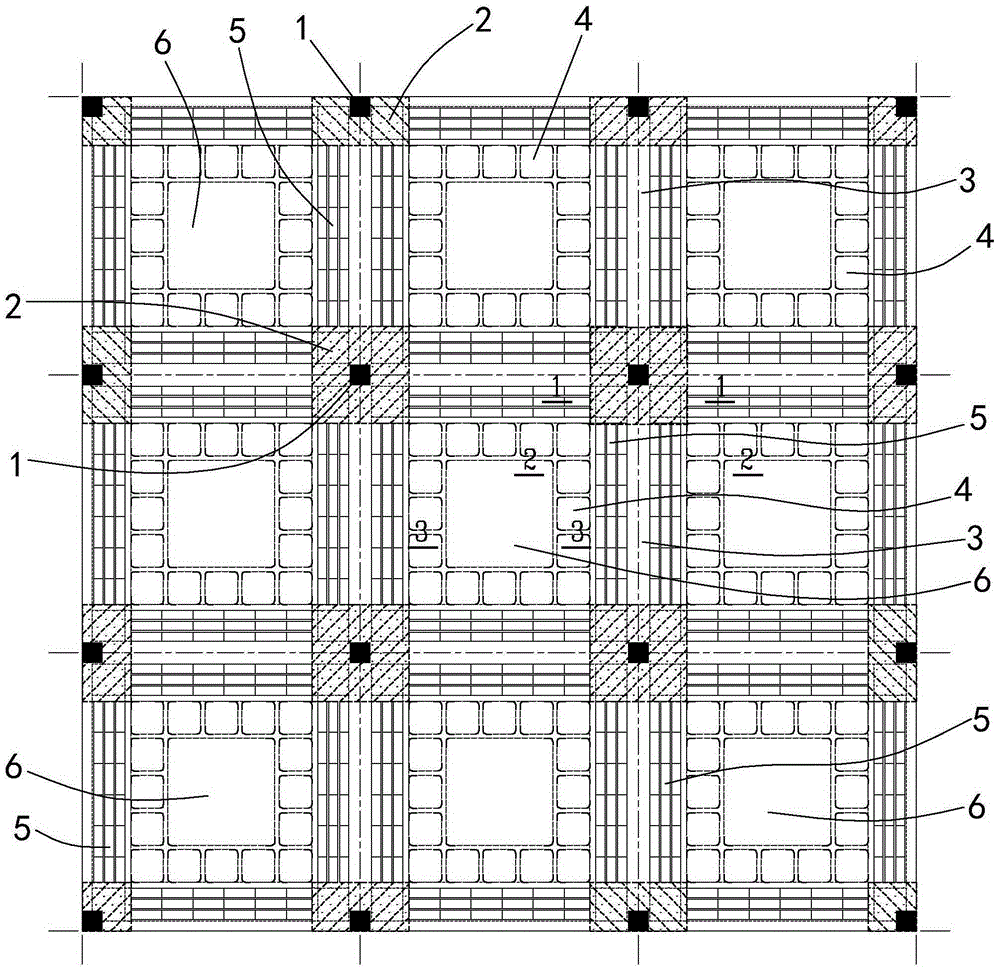

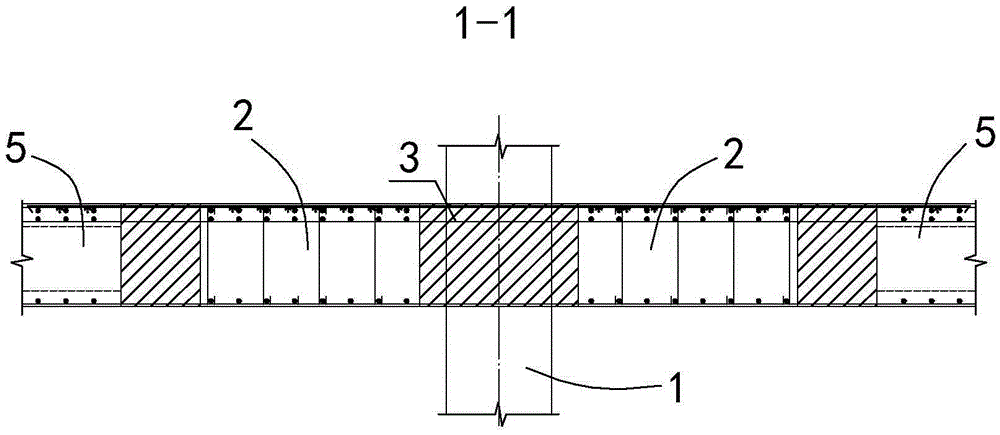

[0039] Such as Figure 2 to Figure 5Shown is a hybrid floor that can reduce its own weight and has good structural rigidity. The floor is a long-span floor with a span of 10m. This floor is also suitable for large-span floors with a span of 7-12m.

[0040] The floor covers include columns 1, column caps 2, concealed beams 3 and multiple square ribbed beams 4. The side length of the densely ribbed beams 4 is 1m. Uniform lattice distribution, the number of column caps 2 is equal to the number of columns 1, each column cap 2 is poured around a corresponding column 1, and the concealed beams 3 are multiple beams arranged in a criss-cross pattern, adjacent to each other A hidden beam 3 is arranged between the vertical columns 1, and every four vertical columns 1 and four hidden beams 3 form a square rigid frame, thereby forming a plurality of uniformly arranged rigid frames, and the four vertical columns 1 are respectively located in the On the four vertices of the square, four hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com