A lobby background wall and its manufacturing process

A production process and background wall technology, applied in covering/lining, building, building structure, etc., can solve the problems of human harm, high construction cost, inconvenient construction, etc., achieve good sound insulation and noise reduction effect, simple structure and process , increase the effect of beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

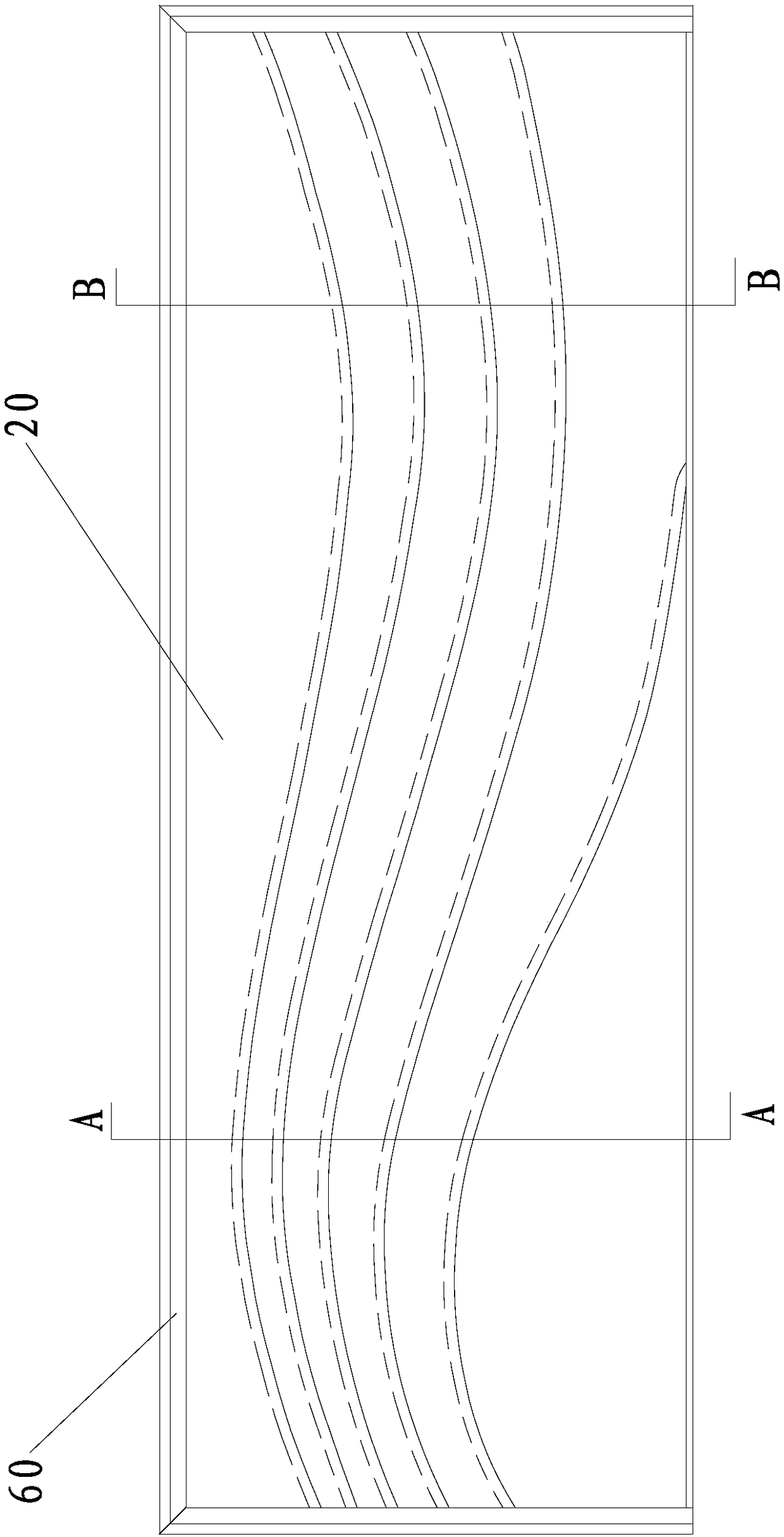

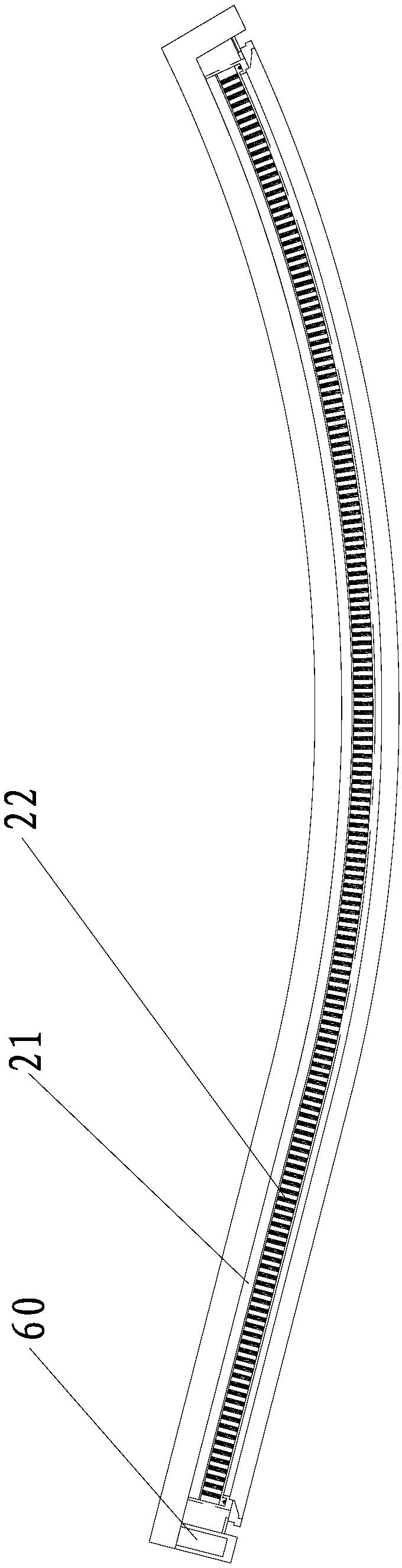

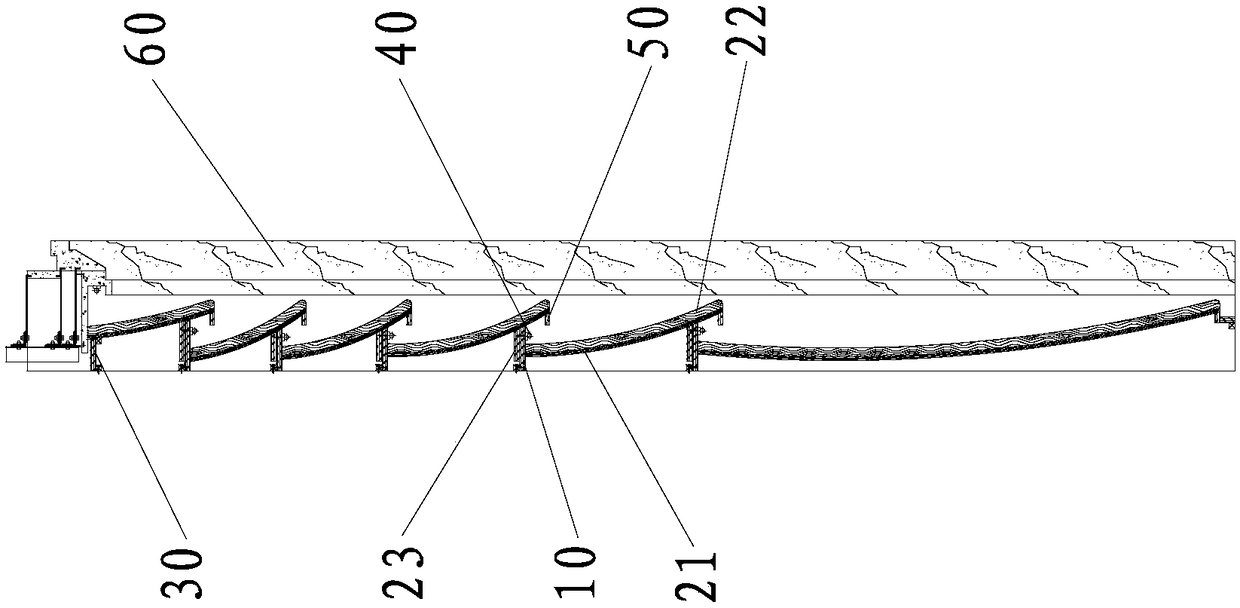

[0039] like Figure 1-5 As shown, the lobby background wall provided by this embodiment includes a plurality of wavy base panels 10 and a plurality of wave units 20 stacked in sequence from the floor to the ceiling, and of course may also include a wall frame for defining the boundary of the wall 60. The wall frame 60 can be a conventional background wall frame, which is not the focus of the present invention, and will not be described in detail here.

[0040] Each base plate 10 is located at the position where every two adjacent wave units 20 overlap each other, that is, the number of base plates 10 is one less than the number of wave units 20. In this embodiment, there are six wave units 20 , the six wave units 20 are stacked together sequentially. For the convenience of expression, in this embodiment, each wave unit 20 is referred to as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com