A device for automatic deburring and grinding

A deburring, automatic technology, applied in metal processing and other directions, can solve problems such as low efficiency and product accuracy cannot be guaranteed, and achieve the effect of avoiding needle breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

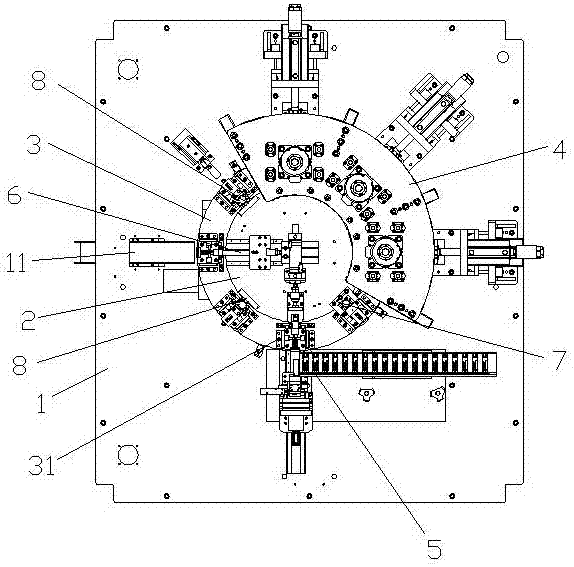

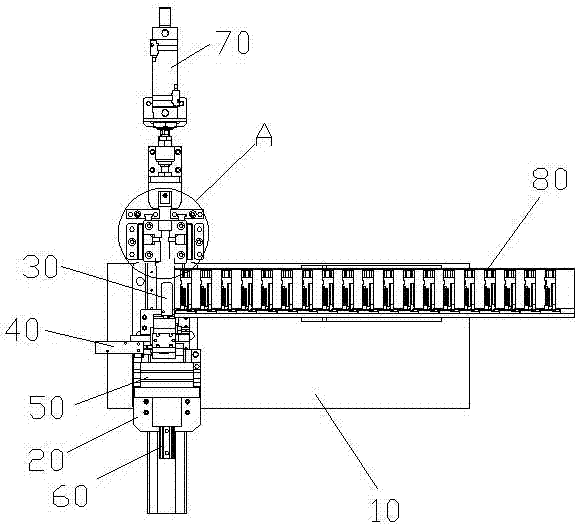

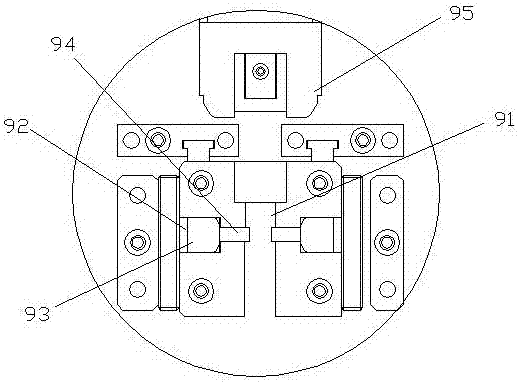

[0023] Such as figure 1 and Figure 6 As shown, a device for automatic deburring and grinding includes a chassis 1, a center plate 2 and a turntable 3 with the same height are arranged on the top of the chassis 1, and a number of A product fixing seat 31, the chassis 1 on the outside of the rotating disk 3 is provided with a feeding device 5 and a material receiving port 11, and there is at least one group of symmetrically arranged deburring devices on the upper and lower sides of the rotating disk 3 of the feeding device 5 and the material receiving port 11 41. The deburring device 41 includes a lower pressing plate 42 and a pressing plate 43 that can move up and down relative to the lower pressing plate 42. The pressing plate 43 is provided with a plurality of guide grooves 44 for blades to pass through.

[0024] In this embodiment, the feeding device 5 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com