Encapsulating method of high-strength chip

A chip packaging, high-strength technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing the service life of the chip, affecting the normal operation of the chip, and lack of stability of the chip packaging structure, so as to improve the strength and Toughness, multiple protections, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

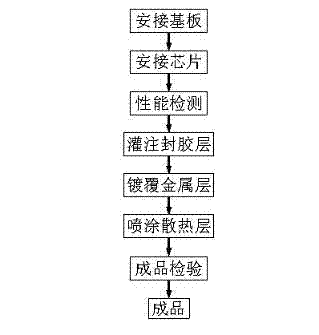

[0016] figure 1 It is a process step diagram of a high-strength chip packaging method in an embodiment of the present invention; the high-strength chip packaging method mainly includes the following steps: a) mounting the substrate, b) mounting the chip, c) performance testing, d) pouring the sealant layer, e) Plating metal layer, f) Spraying heat dissipation layer, g) Finished product inspection.

[0017] The specific implementation steps are as follows:

[0018] a) Install the substrate, the substrate is bonded to the metal pins with thermosetting adhesive, and the electrical connection with the metal pins is realized through gold wires;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com