Aluminum alloy section bar

A technology of aluminum alloy profiles and left profiles, which is used in wing sash frames, windows/doors, building components, etc., can solve the problems of difficult parts processing, reduced service life, and lack of firmness, and achieves good sound insulation, improved service life, The effect of quiet living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

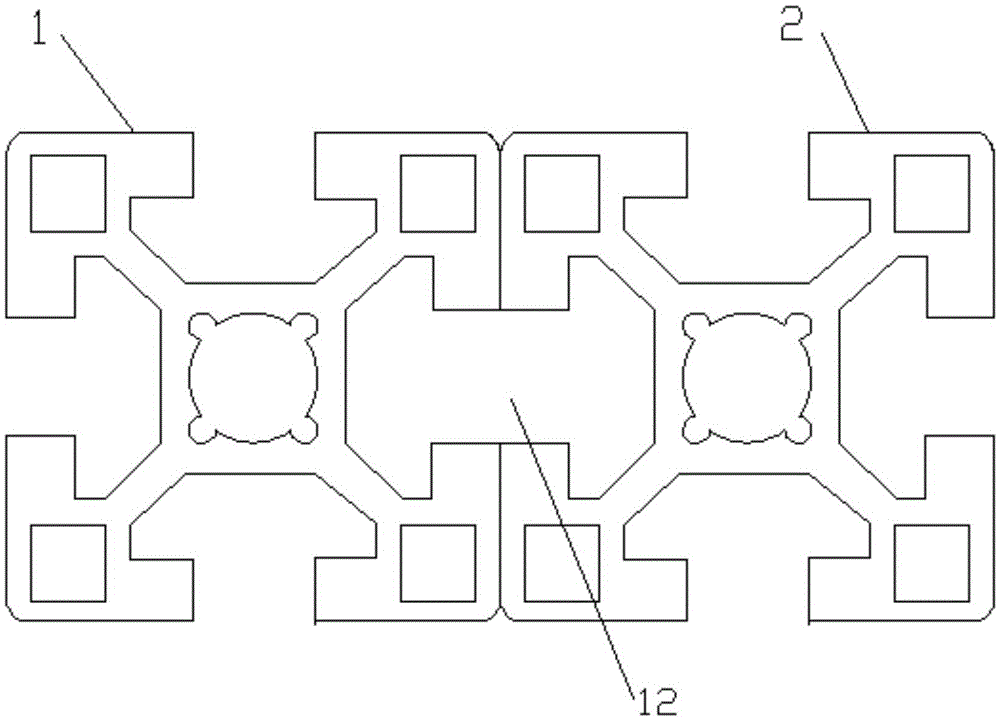

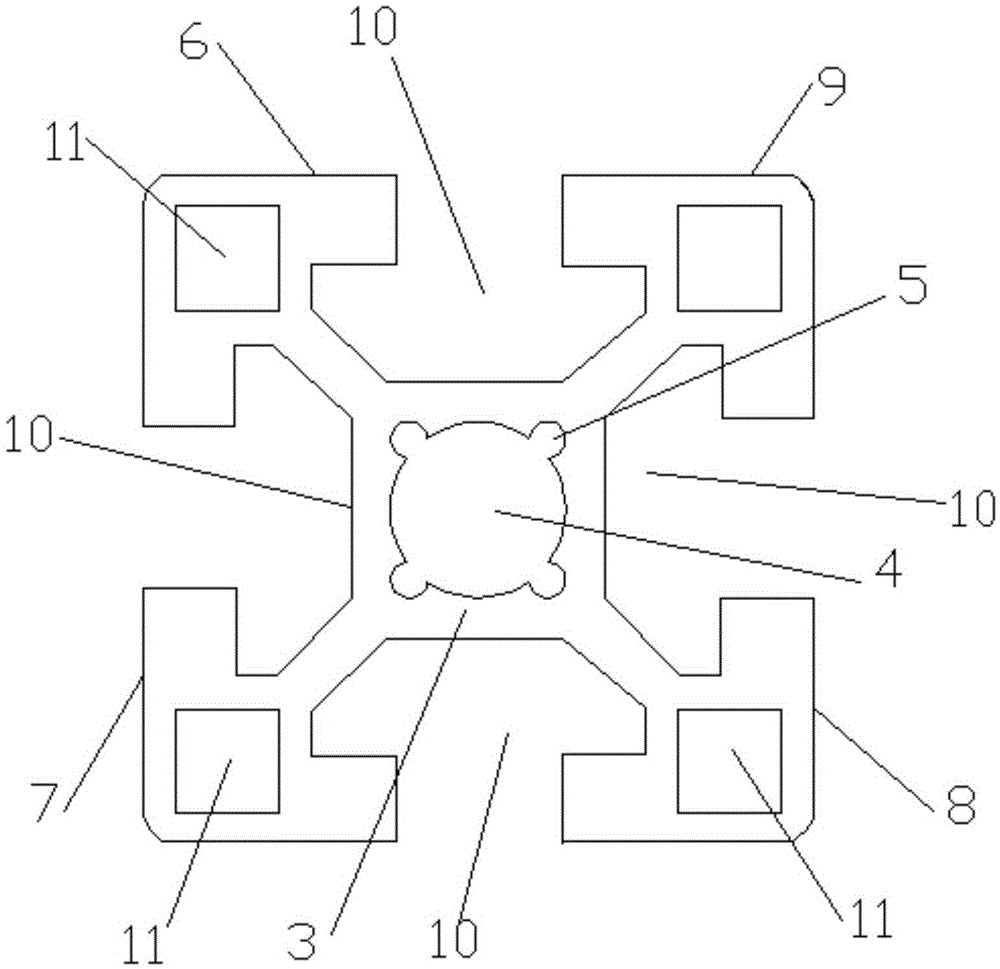

[0017] Such as figure 1 , 2 As shown, the technical solution of the present invention is an aluminum alloy profile including a left profile body 1 and a right profile body 2. The right side of the left profile body 1 is fixedly connected to the left side of the right profile body 2. The left profile body 1 includes a box body 3. A through cavity 4 is opened in the box body 3 along its length. The through cavity 4 is provided with a sound insulation member. The through cavity 4 is a circular through cavity. The four corners of the through cavity are provided with arc grooves 5 protruding outward, and the upper left support 6, the lower left support 7, the upper right support 8 and the lower right support are respectively provided at the 4 corners outside the frame 9, the upper left support 6 and the lower left support 7, the upper left support 6 and the upper right support 8, the lower left support 7 and the lower right support 9, the upper right support 8 and the lower right sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com