Method for measuring nonuniform temperature field in wall and wall thickness

A measurement method and temperature field technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that the ultrasonic solid temperature measurement method is difficult to meet the actual needs of the project, and achieve the effects of broadening the scope of application, eliminating influence, and avoiding manufacturing and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

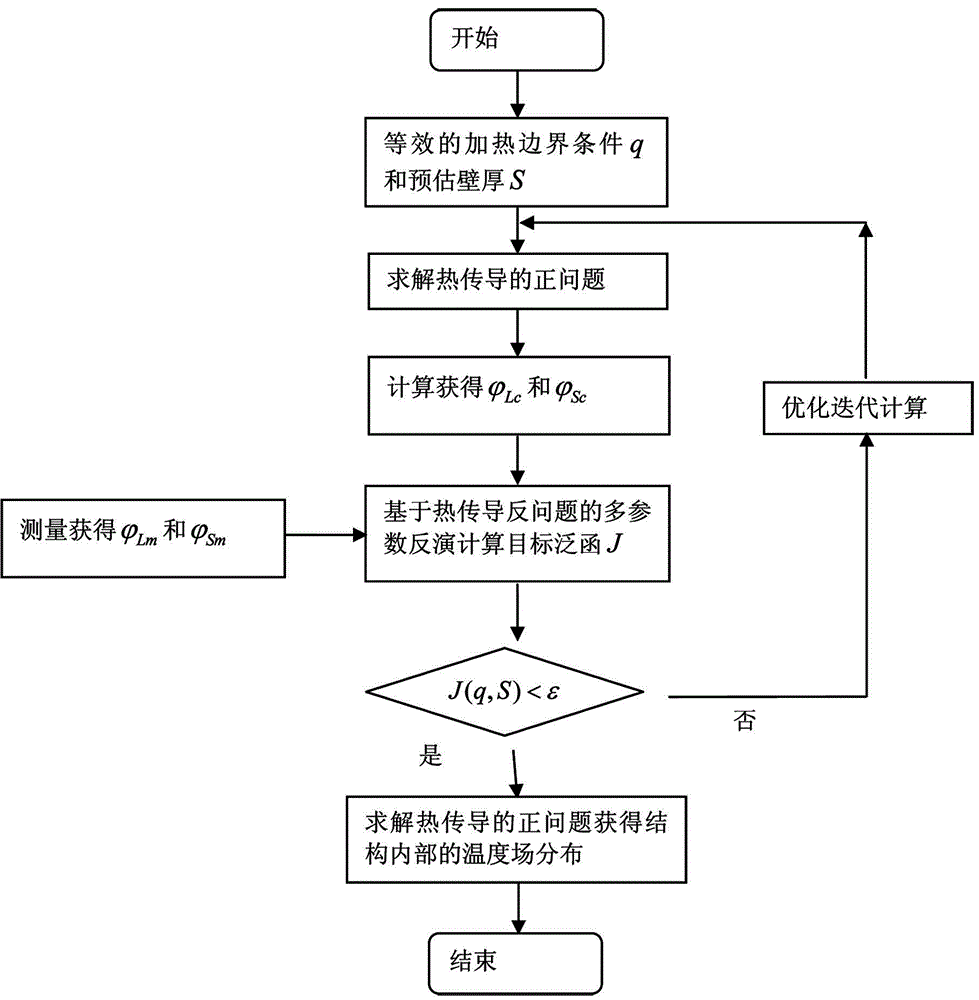

[0022] Such as figure 1 A measurement method for simultaneously obtaining the non-uniform temperature field and wall thickness inside the wall is shown, and the basic steps are:

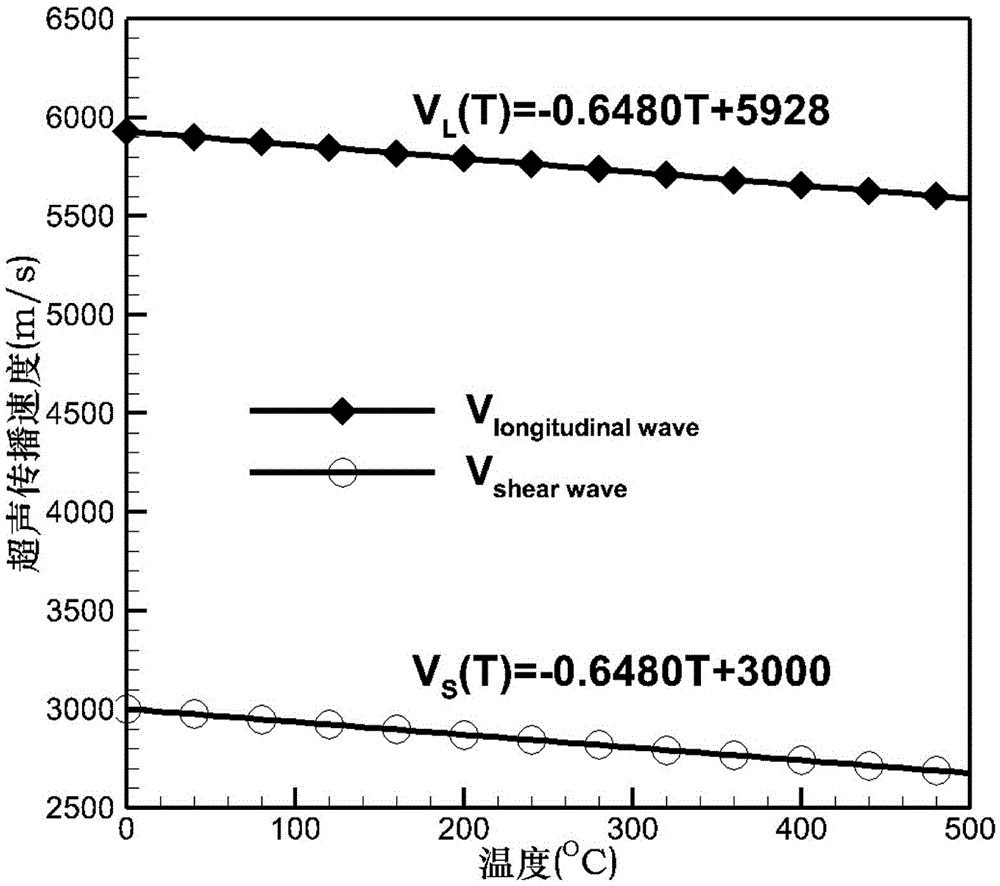

[0023] (1) Obtain the relationship between the longitudinal wave / shear wave velocity and temperature in the tested specimen (Q235 steel) from the calibration test, such as figure 2 shown;

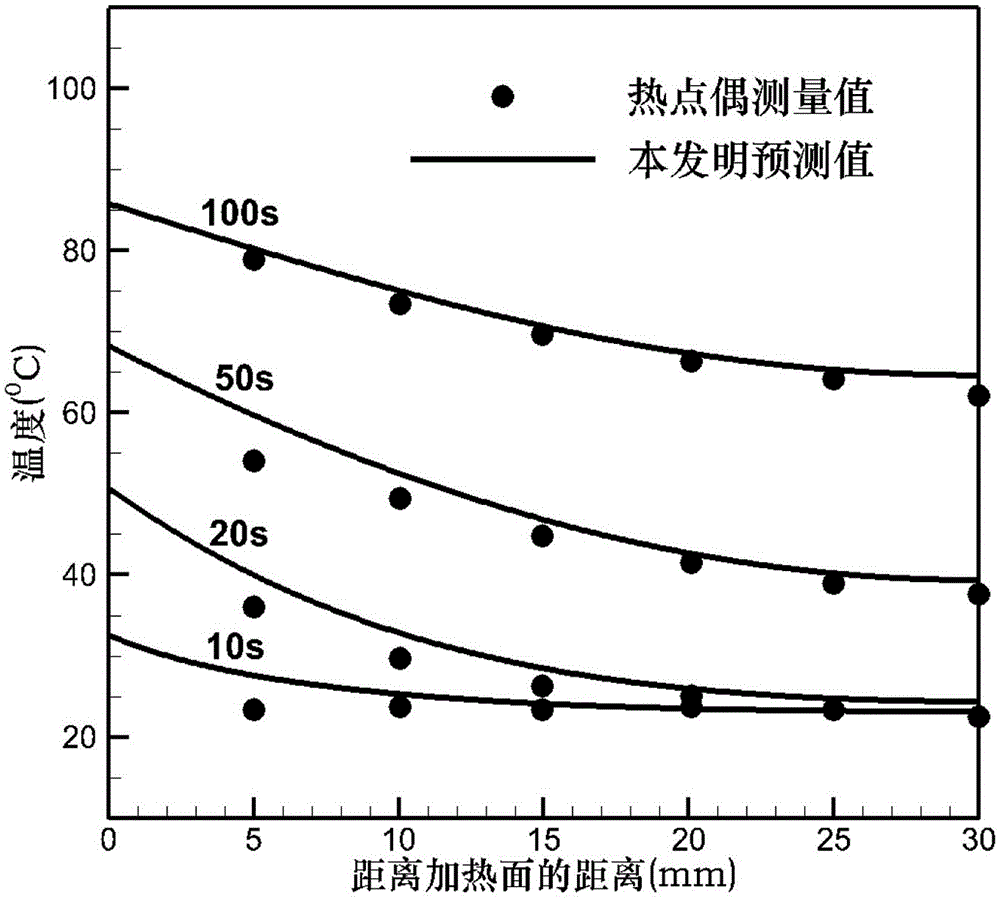

[0024] (2) For the steel specimen (length × width × height is 200 × 50 × 30mm, the thickness of the heating surface measured by the vernier caliper is 30.21mm), using the infrared method to obtain a large area of the specimen surface at the time of 10s, 20s, 50s and 100s The temperature is 26 , 26.3 , 38.7 and 62.3 ;

[0025] (3) Based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com