An apparatus able to accurately apply pressures on a miniature chip

A micro-chip technology, applied in the direction of mechanical pressure/force control, non-electric variable control, instruments, etc., can solve the problems of affecting the chip, poor control of the uniformity of applied force, and inability to accurately control the force, so as to ensure stability Effects on sex and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described in detail below.

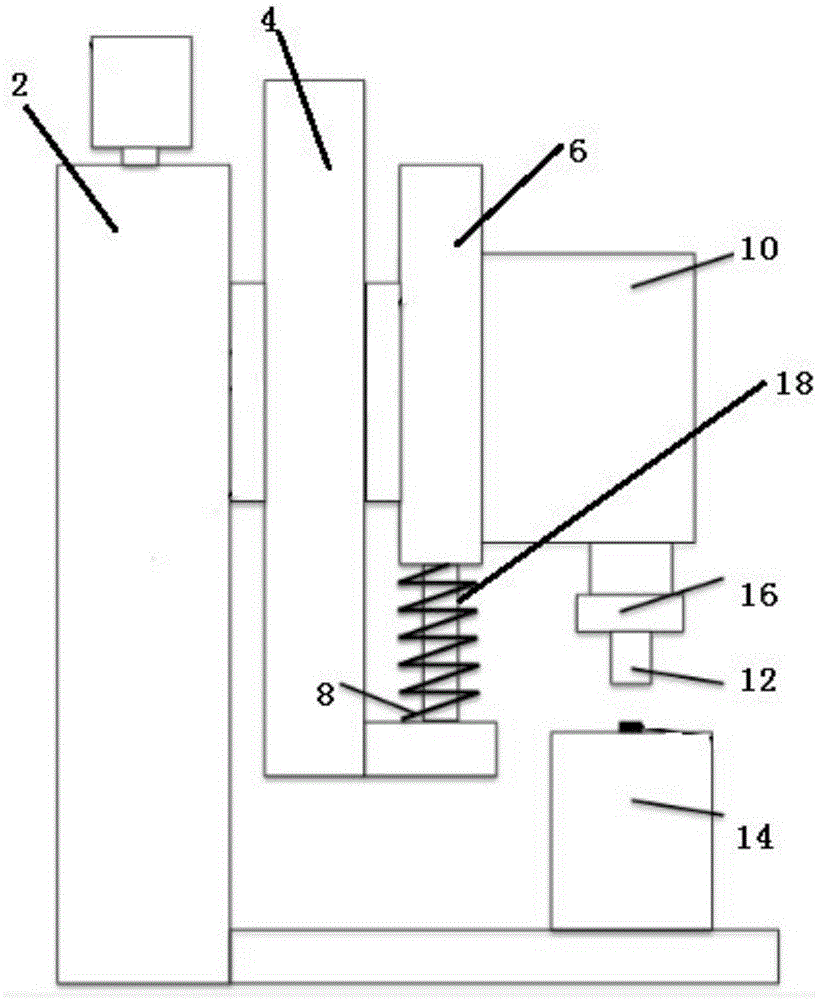

[0015] like figure 1 As shown, the present invention includes a base 2 and a lifting device 4 that is connected to the base 2 and can be raised and lowered, and is characterized in that it also includes:

[0016] - the casing 6, the bottom of which is connected to the lifting device 4 with a spring 8;

[0017] - weight block 10, which is a counterweight device, which is connected to the side wall of the casing 6, and a pressure head 12 is fixedly connected under the weight block 10;

[0018] - a workbench 14 arranged directly below the indenter 12 , the microchip is mounted on the upper surface of the workbench 14 .

[0019] As a further improvement of the present invention, a pressure sensor 16 is also connected between the pressure head 12 and the weight block 10 .

[0020] As a further improvement of the present invention, a vertical columnar guide rod 18 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com