Multi-functional assembly machine

A multi-functional, machine-based technology, applied in conveyor objects, transportation and packaging, metal processing, etc., can solve problems such as high labor costs, disadvantageous automation of the entire line, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

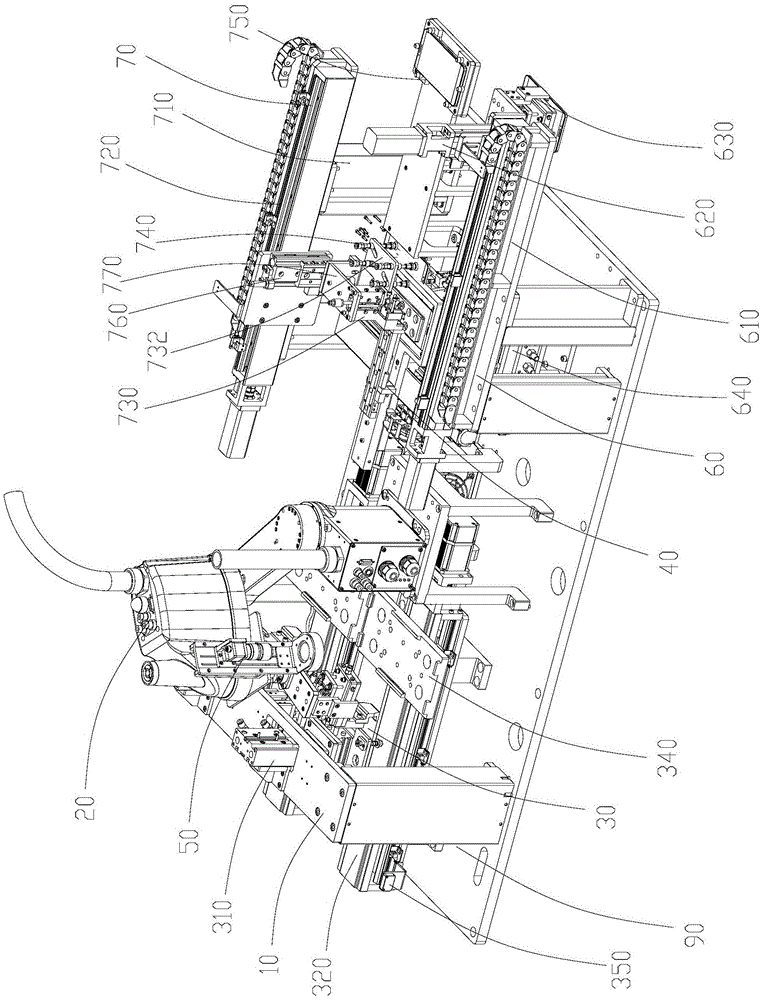

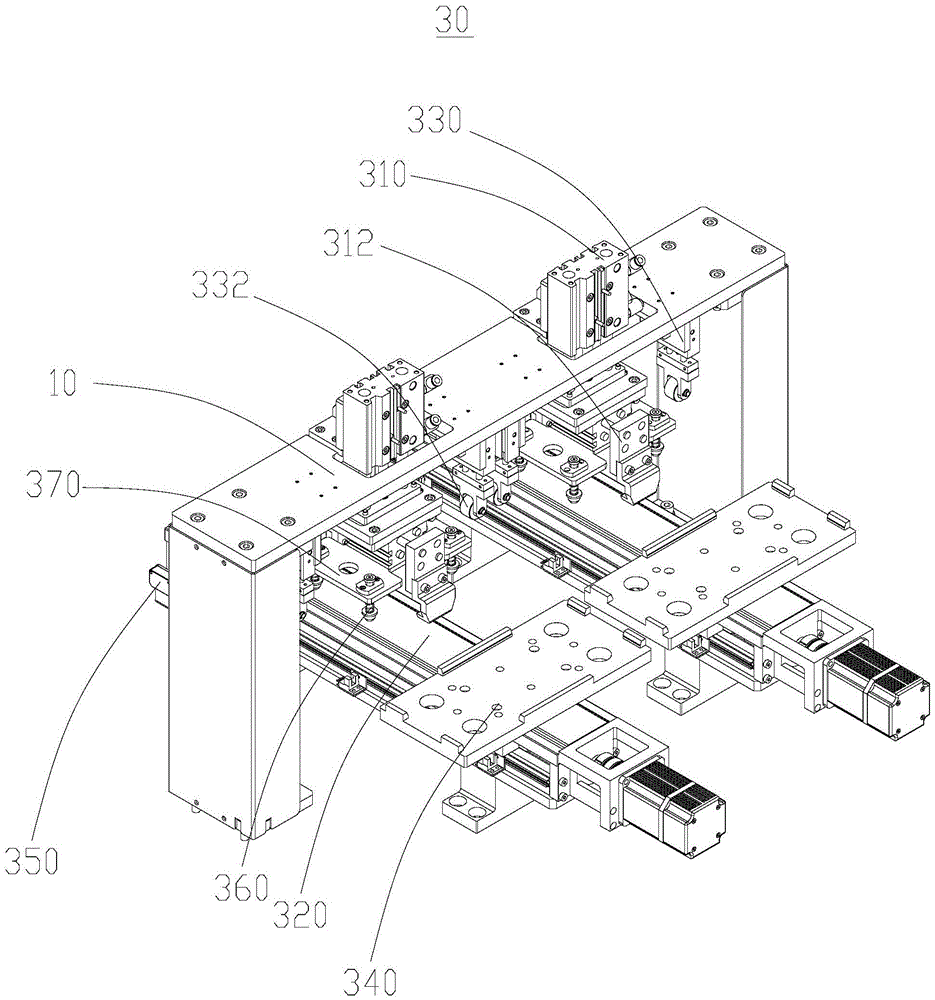

[0026] like Figures 1 to 4 As shown, a multifunctional assembly machine platform includes a support frame 10, a robot 20, a disassembly mechanism 30, a ground wire mechanism 40 and a controller. The robot 20 is provided with a vision mechanism 50, and the vision mechanism 50, the robot 20, The dismounting mechanism 30 and the ground wire mechanism 40 are electrically connected to the controller respectively. The dismounting mechanism 30 includes a first lifting cylinder 310, a first sliding table 320 and two buckle-off cylinders 330. The first lifting cylinder 310 And the buckle-off cylinder 330 is arranged on the support frame 10, and the two buckle-off cylinders 330 are respectively arranged on both sides of the first lifting cylinder 310, and the first lifting cylinder 310 is provided with a first claw 312, and the first lifting cylinder 310 is provided with a first claw 312, and the first lifting cylinder 310 A slide table 320 is located below the support frame 10, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com