Prefabricated water-permeable strip block for paving pavement and surface layer structure

A sidewalk and strip technology, applied in roads, pavements, roads, etc., can solve the problems of poor cost performance and high cost, and achieve the effects of low cost, ecological problems, and good anti-warping function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

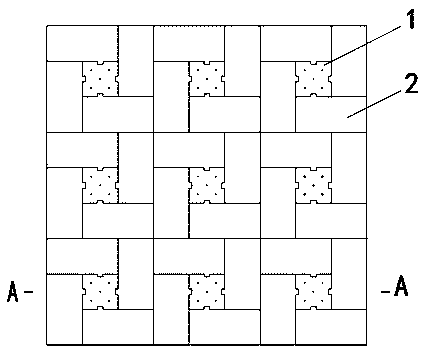

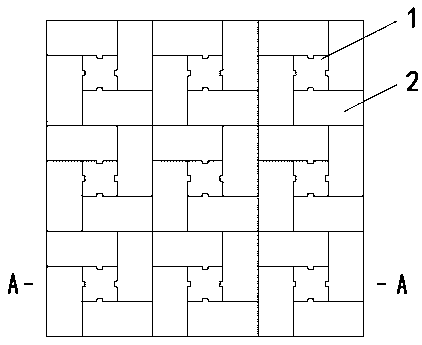

Image

Examples

Embodiment 1

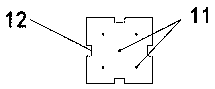

[0045] Such as image 3 As shown, the top surface of the prefabricated permeable bar 1 is flush with the top surface of the pavement brick, and coarse sand is filled in the permeable hole 11, so that the prefabricated permeable bar 1 is directly connected to the cushion from the surface layer, which can ensure The rainwater seeps down at the fastest speed, part of it flows into the roadside ecological side ditch along the cushion, and part of it continues to seep down to the soil foundation to replenish groundwater.

Embodiment 2

[0048] Such as Figure 5 Shown, the present invention also provides a kind of construction method of novel permeable sidewalk pavement, and it comprises the following steps:

[0049] S0, to ensure that the road bed compaction degree ≥ 90%;

[0050] S1. Pave the graded crushed stone or natural gravel cushion with a thickness of 10-15cm;

[0051] S2. The prefabricated permeable strips are positioned and inserted into the graded crushed stone or natural gravel cushion to a depth of 5-10cm;

[0052] S3, C20 cement concrete base is poured around the permeable strips, pay attention not to skew the prefabricated permeable strips;

[0053] S4. Meet the 7d compressive strength of the C20 cement concrete base, and lay cement mortar for the leveling layer;

[0054] S5. When paving pavement tiles, ensure that they are stable, free of warping and smooth on the surface.

[0055] Compared with the existing technology, the prefabricated permeable strips are used in the manufacturing and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com