PBT composite material and preparation method thereof

A composite material and PBT resin technology, applied in the field of PBT composite materials and preparation, can solve the problems of affecting the mechanical properties of materials, not durable enough, and easy to fail in antistatic properties, and achieve excellent antistatic effect, good anti-warping, and good electrical conductivity. Effects of performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

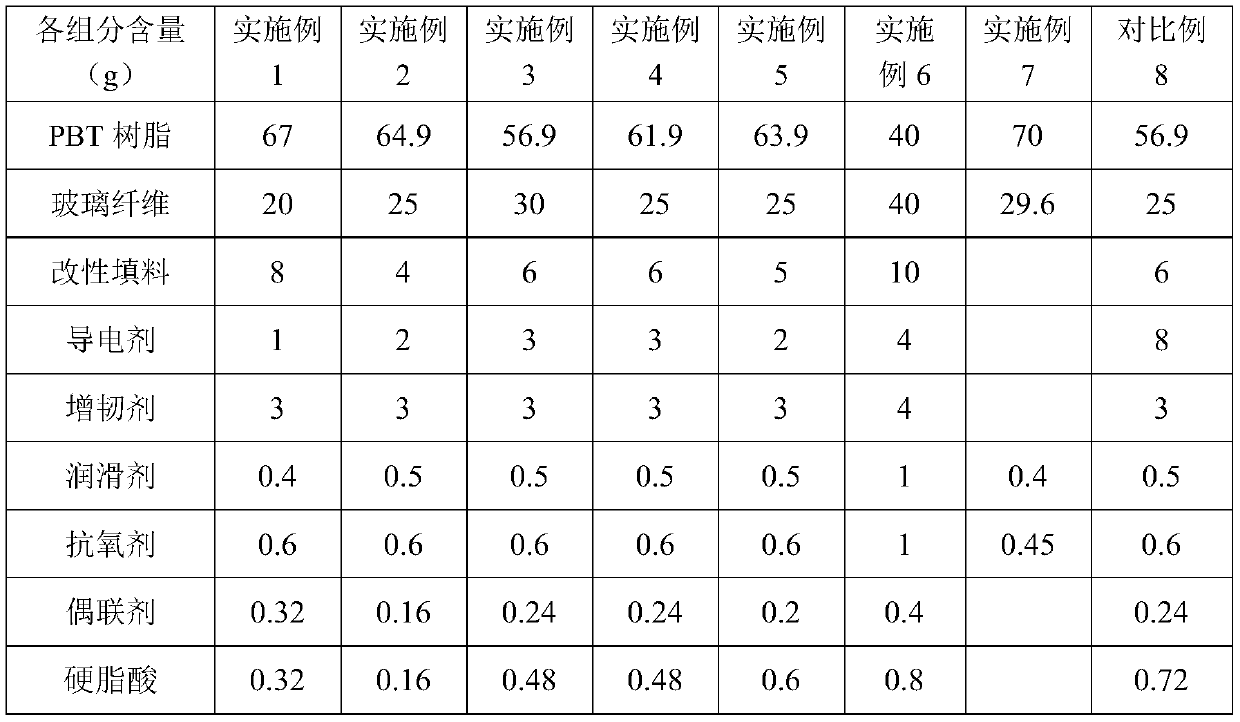

Embodiment 1

[0035] Weigh each component by weight:

[0036] PBT resin is 67g; glass fiber is 20g; modified filler is wollastonite 8g; conductive agent is graphene 1g; toughening agent is ethylene-methyl acrylate-glycidyl methacrylate terpolymer 3g; The agent is β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.4g, tris(2,4-di-tert-butylphenyl) phosphite antioxidant 0.2g; lubricant is pentaerythritol stearate 0.4g, silane coupling agent KH5700.32g, stearic acid 0.32g.

[0037] Among them, wollastonite is pre-surface-treated by silane coupling agent and stearic acid. The specific treatment method is: after dissolving and diluting the silane coupling agent with absolute ethanol, atomize and add to the wollastonite in the high-speed mixer, silane After the coupling agent is added, carry out fluidized bed drying reaction for 2 hours; then add stearic acid to carry out fluidized bed homogenization reaction, and after 1 hour of reaction, the modified spare filler can be obtained. ...

Embodiment 2

[0041]PBT resin is 64.9g; glass fiber is 25g; modified filler is whisker 4g; conductive agent is carbon nanotube 2g; toughening agent is ethylene-butyl acrylate copolymer 3g; antioxidant is β-(3,5 -Di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.4g, tris(2,4-di-tert-butylphenyl) phosphite antioxidant 0.2g; lubricant is ethylene Bis fatty acid amide 0.5g, silane coupling agent KH570 0.16g, stearic acid 0.16g.

[0042] The whiskers are pre-surface treated with silane coupling agent and stearic acid. The specific treatment method is: after dissolving and diluting the silane coupling agent with absolute ethanol, atomize and add to the whiskers in the high-speed mixer, silane coupling After the agent is added, the fluidized bed drying reaction is carried out for 2 hours; then stearic acid is added to carry out the fluidized bed homogenization reaction, and after the reaction is completed for 1 hour, the modified spare filler can be obtained. Among them, the atomization spe...

Embodiment 3

[0046] PBT resin is 59.6g; glass fiber is 30g; modified filler is wollastonite 6g; conductive agent is carbon nanotube 2.4g / graphene 0.6g; toughening agent is ethylene-methyl acrylate-glycidyl methacrylate Terpolymer 3g; antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.4g, tris(2,4-di-tert-butyl phosphite) phenyl) ester antioxidant 0.2g; lubricant is pentaerythritol stearate 0.5g, silane coupling agent KH570 0.24g, stearic acid 0.48g.

[0047] Among them, wollastonite is pre-surface-treated by silane coupling agent and stearic acid. The specific treatment method is: after dissolving and diluting the silane coupling agent KH570 with absolute ethanol, atomize it and add it to the wollastonite in the high-speed mixer. After adding the silane coupling agent KH570, carry out the fluidized bed drying reaction for 2 hours; then add stearic acid to carry out the fluidized bed homogenization reaction, and after the reaction is completed for 1 hour, the modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com