A sliding variant adjustable caret intake

A kind of air inlet and variant technology, which is applied to the combustion of the air inlet of the power plant, the power plant on the aircraft, the arrangement/installation of the power plant, etc., and can solve the complex shape of the air intake parts, the separation of the airflow, and the strong reflection signal and other issues to achieve the effect of improving the performance of high Mach number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

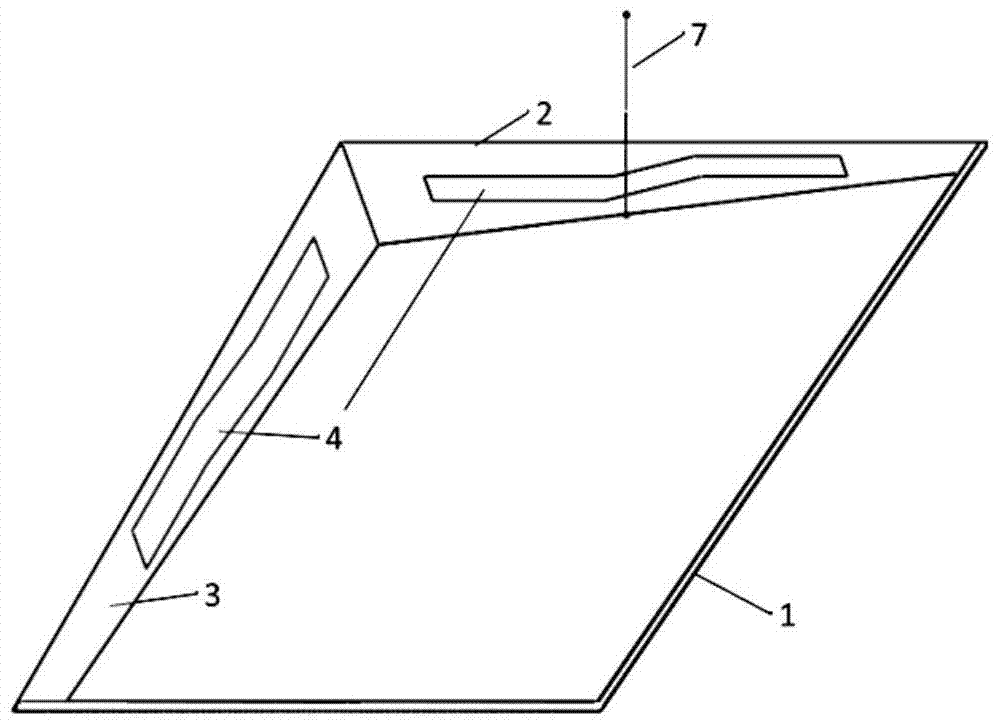

[0029] (1) As attached figure 1 As shown, the air inlet section is a parallelogram with a double chamfered lip 1;

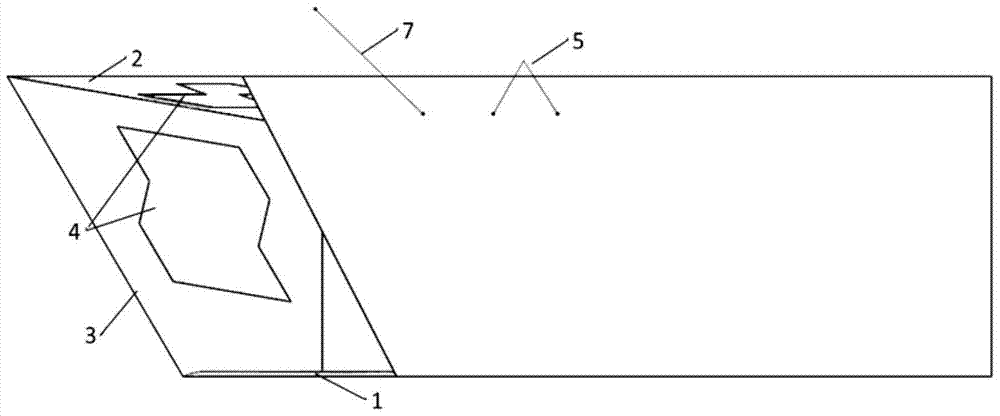

[0030] (2) As attached figure 2 As shown, an upper sidewall fixed compression swash plate 2 and an inner wall fixed compression swash plate 3 are arranged behind the lip 1, and attachment surfaces are provided on the upper side wall fixed compression swash plate 2 and the inner side wall fixed compression swash plate 3 Layer desorption opening area 4;

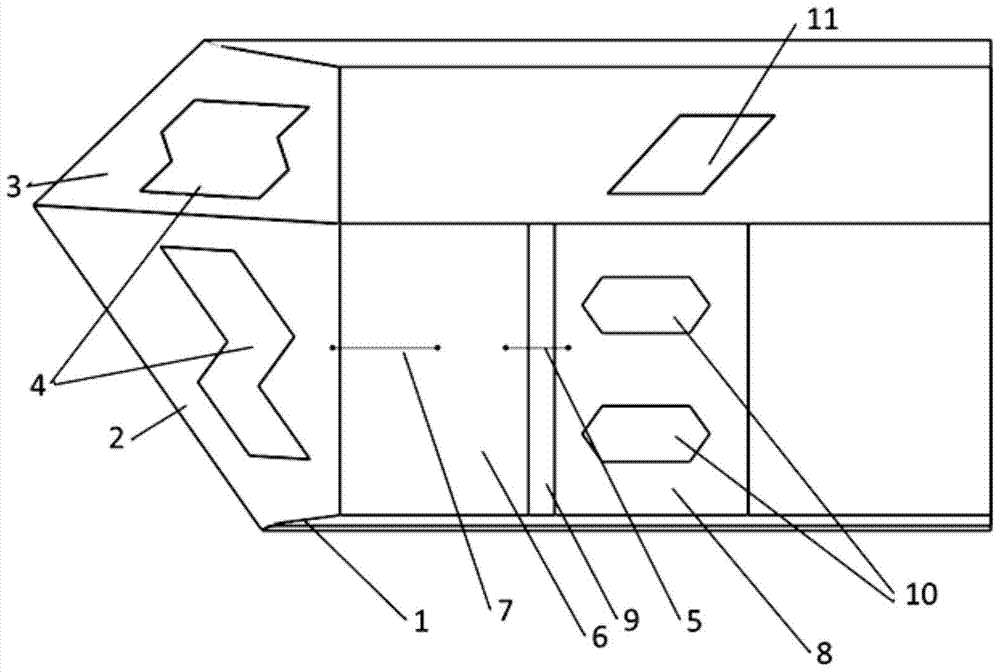

[0031] (3) As attached image 3 As shown, after the compression swash plate 2 is fixed on the upper side wall, there is hinged a sliding variable adjustable compression swash plate 6 driven by the compression swash plate driving piston rod 7, which moves with the sliding variant through the expansion swash plate follower hinge 5 Expansion inclined plate 8 is connected;

[0032] (4) As attached image 3 As shown, the flexible honeycomb sealing structure 9 keeps the seal between the adjustable compression swas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com