Special-shaped cross-section fiber aggregate, fiber structure and polymer composite fiber

A technology of fiber aggregates and special-shaped cross-sections, which can be used in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., and can solve the problems of not greatly improving the moisture absorption effect and inhibiting dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the polymer composite fiber of the present invention can be listed as follows: 50-90% of the A component of the poorly soluble polymer chip and 10-50% of the B component of the easily soluble polymer chip are melted and composited through the spinneret. Spraying, spinning, and coiling to obtain composite fibers.

[0042] The component A of the poorly soluble polymer chip is a non-eluting polymer, preferably a polyamide polymer or a polyester polymer. Polyester-based polymers include polyethylene terephthalate, polytrimethylene terephthalate, polybutylene terephthalate, and modified copolymers thereof. Examples of polyamide-based polymers include nylon 6, nylon 66, and modified copolymers thereof.

[0043] The easily soluble polymer chip B component is preferably a soluble copolyester chip, which is mainly formed by copolymerization of terephthalic acid and ethylene glycol, and contains at least the third comonomer isophthalic acid 5-sulfonate ...

Embodiment 1

[0097] 80 wt% polyethylene terephthalate (PET) and 20 wt% soluble polyester chips were pre-crystallized and dried to less than 100 ppm, respectively, and put into each silo, and passed through each screw at a temperature of 250-300°C Melting, the discharge volume is controlled by a separate metering pump, and the primary composite fiber is spun out through the composite spinning assembly whose temperature is controlled by the spinning box at about 290°C, and cooled and solidified under the condition of side blowing wind speed of 40m / min. , and then oil the fibers evenly through the oil nozzle to bundle the fibers and reduce friction. The oil supply rate is 1.0%.

[0098] The fibers that have been oiled and bundled pass through the spinning shaft, are entangled by the pre-interlacer, enter the first hot roller 1HR (temperature is 80°C), and are wound on the first hot roller for 6 turns, and then pass through the second hot roller. The roll 2HR is also wound 6 times on it (tempe...

Embodiment 2

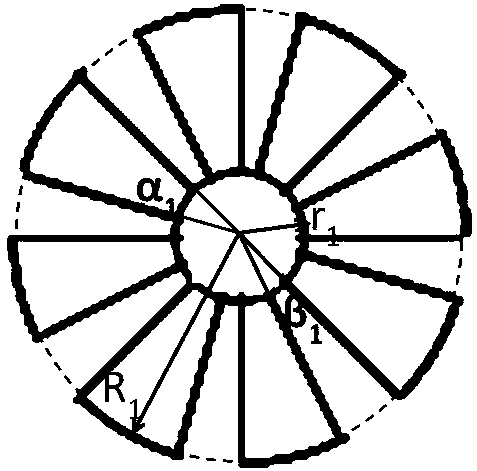

[0104] 80 wt% polyethylene terephthalate (PET) and 20 wt% soluble polyester chips were pre-crystallized, dried to below 100 ppm, and spun as in Example 1 to obtain composite fibers. Use SEM to observe the section of the composite fiber, the number of leaves of the first component polyethylene terephthalate is 12, and calculate the filament factor K 2 =4.3.

[0105] The above-mentioned fibers were made into fabrics, and the fabrics were reduced in NaOH solution with a concentration of 1% and a liquor ratio of 150 for 35 minutes, and the fabric reduction rate was 20%.

[0106] Use SEM to observe the section of the heterosexual fiber, the fiber section is in the shape of 12 leaves, and the filament factor is K 1 =4.3.

[0107] It is measured that the fabric has water absorption and quick-drying performance. The water absorption performance of climbing is tested with the Japanese standard JISL 1907:2010, and the height of the liquid water rises to 85mm; the water absorption is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com