A cotton-feeling knitted fabric

A technology of knitted fabrics with a cotton feel, applied in the field of cotton-feel knitted fabrics, can solve the problems of weaving fine denier warp yarns, the movement stretchability is not as good as that of knitted fabrics, and the limitation of capillary effect, etc., and achieve good water absorption and quick-drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

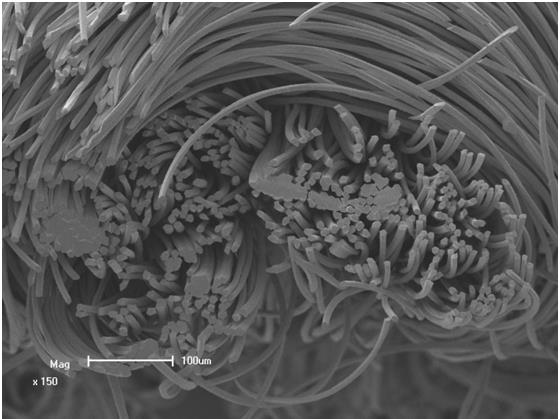

Image

Examples

Embodiment 1

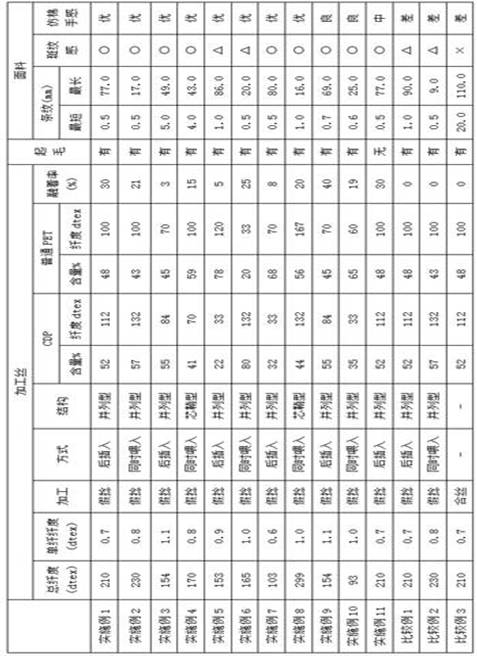

[0042] On the 28-needle single-sided circular knitting machine, 100% of the 210dtex-288f side-by-side mixed fiber false-twisted processed yarn obtained by the rear insertion type is selected (the fusion rate is 30%, and the content ratio of CDP: ordinary PET is 52:48). Plain stitches are woven to obtain gray fabrics, and then refined (90°C×20 minutes), CDP dyed (120°C×30 minutes), ordinary PET dyed (130°C×40 minutes), finished products are shaped (160°C×90 seconds), The cotton-feeling knitted fabric of the present invention is obtained through fluff processing.

[0043] The surface of the obtained fabric has dyed parts A and B of different lengths, rich and natural mottling, and excellent cotton-like hand feeling. The performance parameters are shown in Table 1.

Embodiment 2

[0045] Select the 230dtex-288f side-by-side mixed fiber false-twisted processed yarn obtained by feeding at the same time (the fusion rate is 21%, the content ratio of CDP: ordinary PET is 57:43), and the rest are the same as in Example 1 to obtain the present invention. Cotton-feel jersey.

[0046] The surface of the obtained fabric has dyed parts A, B and C of different lengths, with rich and natural mottling, and excellent cotton-like hand feeling. The performance parameters are shown in Table 1.

Embodiment 3

[0048] Select the 154dtex-144f side-by-side mixed fiber false-twisted processed yarn (melting rate 3%, CDP: common PET content ratio is 55:45) obtained by inserting after selection, and the rest are the same as in Example 1 to obtain the cotton of the present invention. Sensual knit fabric.

[0049] The surface of the obtained fabric has dyed parts A and B of different lengths, rich and natural mottling, and excellent cotton-like hand feeling. The performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com